A complete analysis of the key steps of the durability test of adjustable dumbbells

A complete analysis of the key steps of the durability test of Adjustable Dumbbells

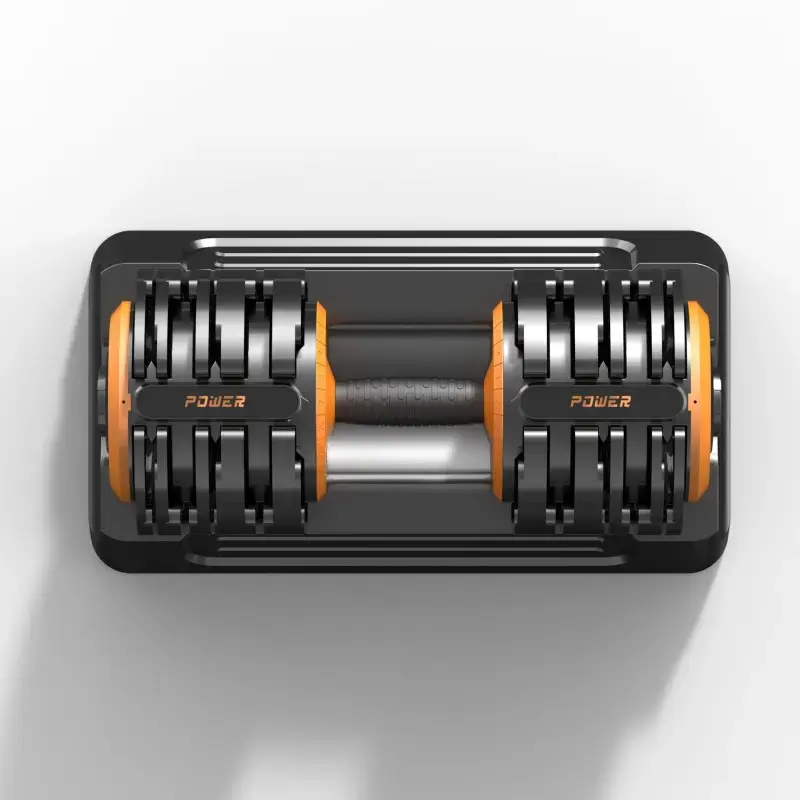

In the field of fitness equipment, adjustable dumbbells are widely favored by fitness enthusiasts and professional fitness people because of their convenience and versatility. For international wholesale buyers, it is crucial to ensure the durability of the adjustable dumbbells they purchase, which is not only related to the market competitiveness of the product, but also directly affects customer satisfaction and brand reputation. This article will explore the key steps of the durability test of adjustable dumbbells in depth, helping you to accurately evaluate product quality and stand out in the fierce international market.

I. Preparation before testing

(I) Clarify the test objectives and standards

Before starting the test, it is necessary to clarify the specific objectives of the test, such as evaluating the performance degradation of dumbbells under long-term use, determining the frequency of use and strength limit they can withstand, etc. At the same time, the corresponding test standards should be formulated based on international standards, industry specifications and target market needs. International standards such as ISO 20957 have detailed provisions on the safety and durability of fitness equipment. These standards can be used as an important reference for testing to ensure that the test results are authoritative and universal.

(II) Sample selection

Selecting representative adjustable dumbbell samples is the basis of testing. An appropriate amount of samples should be drawn from different batches and different suppliers to ensure the diversity and randomness of the samples. The number of samples should be determined based on statistical principles and test accuracy requirements. It is generally recommended to select at least 10-20 sets of dumbbells for testing to ensure that the test results can accurately reflect the quality status of the entire product batch.

(III) Preparation of test equipment and tools

Prepare accurate measuring instruments, such as dynamometers for measuring the locking force of the adjustment mechanism and torque wrenches for detecting the adjustment torque of the knob, to ensure accurate measurement of various performance indicators. At the same time, necessary protective equipment, such as gloves and goggles, should be equipped to ensure the safety of testers during operation.

II. Appearance and structural inspection

(I) Appearance quality inspection

Carefully check the surface treatment of the adjustable dumbbells, including the uniformity and firmness of the coating. High-quality dumbbells should have a smooth and flat surface, and the coating should not have obvious scratches or shedding. For example, for dumbbells using powder coating technology, the coating should be tightly attached to the metal surface and remain intact after wiping test, which can not only prevent the dumbbells from rusting, but also extend their service life.

Observe whether the appearance design of the dumbbell is reasonable, such as whether the shape of the handle conforms to the principles of ergonomics, whether the texture design of the gripping part helps to prevent slipping, etc. The ergonomic handle design can make users more comfortable during use, reduce hand fatigue, and also help improve the training effect.

(II) Structural integrity assessment

Check whether the connection of the various parts of the dumbbell is firm and reliable, and whether there is any looseness or excessive gap. Focus on checking the connection between the adjustment mechanism and the handle and the weight plate. These parts are subject to greater force and friction during use. If the connection is not firm, it is easy to cause adjustment failure or component damage.

Test the stability of the overall structure of the dumbbell, such as placing the dumbbell on an inclined plane at different angles to observe whether it can remain stable without tipping or sliding. Good stability is one of the important factors to ensure the safety of users during use.

III. Adjustment mechanism test

(I) Adjustment flexibility test

Repeatedly operate the adjustment knob or button to check whether it is smooth and without jamming. During the adjustment process, the switching of each gear should be clearly felt, and there should be no obvious change in resistance. For example, the tester can continuously adjust the weight of the dumbbell for multiple cycles at a certain speed and frequency, record the number of smooth adjustments and the number of jams, and evaluate the flexibility of the adjustment mechanism.

Measure the adjustment performance of the adjustment mechanism under different temperature and humidity environments. Because in actual use, dumbbells may face various environmental conditions, such as hot and humid sauna rooms or cold and dry outdoor environments. By simulating these extreme environments, possible problems with the adjustment mechanism can be discovered in advance, such as the solidification of lubricating grease in low temperature environments, resulting in difficulty in adjustment.

(II) Locking reliability test

After adjusting the dumbbell to different weight levels, shake the handle or weight plate vigorously to check whether the locking mechanism is stable and ensure that the weight of the dumbbell will not change due to vibration or other external forces during use. For example, apply an external force of a certain direction and magnitude to the adjusted dumbbell for a period of time, and check whether its weight changes. If there is no change after multiple tests, it means that the locking mechanism has a high reliability.

Use professional testing equipment to measure the locking force of the locking mechanism to ensure that it meets safety standards. Too little locking force may cause the dumbbell to loosen during use, affecting the training effect or even causing a safety accident; while too much locking force may make adjustment difficult and affect the user experience.

IV. Weight plate test

(I) Weight accuracy test

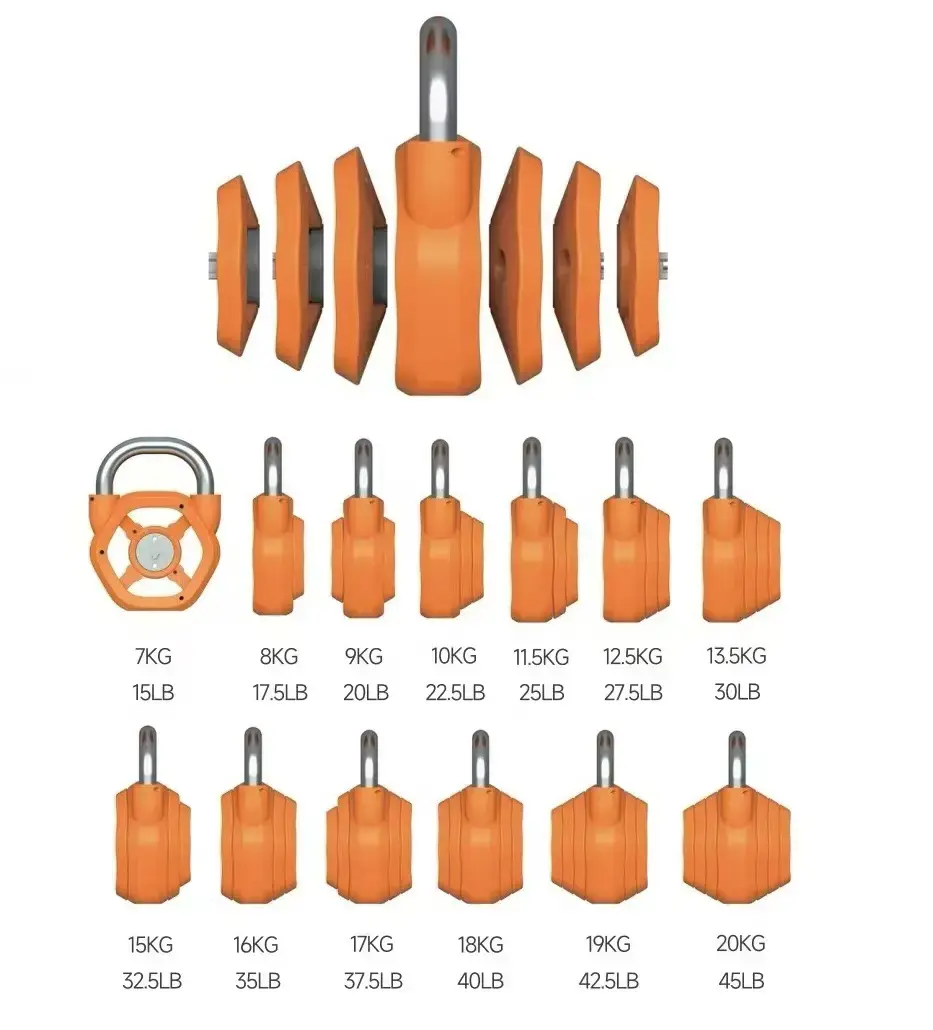

Use a high-precision electronic scale to measure the actual weight of each weight plate and compare it with the nominal weight. Ensure that the weight error of the weight plate is within the allowable range, and the weight error is generally required to be no more than ±5%. For example, the actual weight of a weight plate with a nominal weight of 10 kg should be between 9.5 kg and 10.5 kg. Accurate weight is the basis for ensuring training effect and fairness, especially for professional athletes or users with high strength training requirements.

Randomly select a certain number of weight plates for multiple weight measurements and calculate the degree of dispersion of their weight. If the degree of dispersion is large, it means that the weight consistency of the weight plate is poor, which may be caused by unstable production process or lax quality control, which will affect the overall performance of the adjustable dumbbell.

(II) Wear and deformation resistance test

The wear test of the weight plate can be carried out by simulating long-term friction, such as using sandpaper to rub the surface of the weight plate under a certain pressure and friction number, and then observing the wear of the surface, including the degree of coating shedding and the exposed area of the metal matrix. At the same time, the weight change of the weight plate after a large amount of friction is detected to evaluate its wear resistance.

Place the weight plate in a specific fixture, apply a certain pressure or bending force, keep it for a period of time and then release it to observe whether it can return to its original state or whether it has permanent deformation. The weight plate with strong anti-deformation ability can ensure that the dumbbell can still maintain accurate weight and good appearance after long-term use, without affecting the use effect.

V. Handle test

(I) Grip comfort evaluation

Let testers with different hand shapes and different strength levels hold the dumbbell handles and perform various fitness movements, such as curls and push-ups, to collect their subjective feedback on grip comfort. Focus on the influence of factors such as the thickness, length, and material of the handle on the hand feel. For example, a handle that is too thick may make it difficult for users with smaller hands to hold and cause fatigue; while a handle that is too hard will reduce comfort and affect the training experience.

Use pressure sensors and other equipment to measure the pressure distribution of the handle during holding. By analyzing the pressure data, you can intuitively understand the pressure load of each part of the handle, and then optimize the design of the handle to make it more ergonomic and improve the comfort of holding.

(II) Strength and durability test

The handle is tested for mechanical properties such as bending resistance and torsion resistance. Use a professional material testing machine to apply bending force or torsion force to the horizontal handle at a certain loading rate and loading range until the handle is deformed or damaged, record the maximum load value it withstands, and evaluate whether the strength of the handle meets the use requirements. Generally, the handle should be able to withstand a maximum force that is much greater than that that may occur during normal use to ensure safety under various high-intensity training.

Conduct a simulated use fatigue test, asking the tester to repeatedly use the dumbbell according to common fitness movements and frequencies for a certain period of time (such as hours or days), and observe the changes in the appearance and performance degradation of the handle after long-term use. For example, check whether there are cracks or deformations on the handle surface, whether the anti-slip texture of the grip is severely worn, etc., so as to evaluate the durability of the handle.

VI. Connection component test

(I) Connection firmness test

Check the connection firmness between the connection components such as the adjustment knob and the weight plate fixing nut and the handle and other related components. Use appropriate tools, such as a torque wrench, to tighten and loosen the connection components according to the specified torque value, and check whether there is looseness or thread slippage after repeated multiple times. The firmness of the connection components is the key to ensuring the stability of the overall structure of the dumbbell. Once the connection is loose, it may cause serious consequences such as the weight plate falling off.

Perform a vibration test on the connection components. Place the dumbbell on a vibration table and vibrate it for a long time at a certain vibration frequency and amplitude to simulate the vibration during transportation or use, and observe whether the connection components can remain tight. Vibration testing can detect potential connection problems in advance and improve the reliability and stability of the product.

(II) Corrosion resistance test of connecting parts

Place the connecting parts in specific corrosive environmental conditions, such as a salt spray test chamber. After a certain period of salt spray spraying, observe whether rust, corrosion, etc. appear on the surface. For dumbbells that are often used or stored in humid environments, the corrosion resistance of connecting parts is very important, which can prevent connection failure and product damage caused by corrosion and extend the service life.

VII. Comprehensive performance test

(I) Weight training simulation test

Set different training scenes and action combinations, such as performing multiple sets of curls, presses, squats and rowing with different weights, and let professional testers use adjustable dumbbells to perform high-intensity and long-term training simulations according to the requirements of actual fitness training. During the test, closely observe the overall performance of the dumbbells, including the stability of the adjustment mechanism, the comfort of the handle, the fixation of the weight plate, etc., record any problems and failures, and evaluate its reliability and durability under actual use conditions.

Regularly measure and record the performance parameters of the dumbbells during the test, such as weight changes, changes in adjustment flexibility, etc., draw performance decay curves, and analyze the changes in performance with the time and number of times of use. Through weight training simulation tests, the comprehensive performance of adjustable dumbbells under complex use conditions can be comprehensively evaluated, providing a basis for product improvement and quality improvement.

(II) Comprehensive test of environmental adaptability

The adjustable dumbbells are placed under different combinations of environmental factors such as temperature, humidity, and light for a long time. For example, they are placed in a high temperature and high humidity environment for several weeks or months to observe changes in their appearance, performance, etc. The comprehensive test of environmental adaptability can simulate the use environment of the product in different regions and seasons, discover quality problems caused by environmental factors in advance, and ensure that the product can maintain good performance and appearance under different climatic conditions around the world.

Functional tests are performed on dumbbells under extreme environmental conditions, such as checking whether the adjustment mechanism can still work normally in a low temperature environment, and observing whether the anti-slip performance of the handle is significantly reduced under strong light, etc., to ensure that it can still meet the user's use needs under various harsh environmental conditions.

8. Test result analysis and evaluation

(I) Data collation and statistical analysis

Collate and classify the large amount of data collected during the test, including appearance inspection results, performance test data, environmental adaptability test records, etc. Use statistical methods to analyze the data and calculate the statistical parameters such as the mean, standard deviation, and coefficient of variation of various performance indicators to quantitatively evaluate the durability level of the adjustable dumbbells. Through data collation and statistical analysis, the overall status and fluctuation of product quality can be clearly understood, providing strong data support for subsequent evaluation decisions.

(II) Quality evaluation and problem diagnosis

According to the test data and established test standards, a comprehensive quality evaluation of the durability of the adjustable dumbbells is carried out. Compare the actual test results of various performance indicators with the standard requirements to determine whether there are non-conformities or weak links. For the problems found, deeply analyze the causes of their occurrence, such as design defects, raw material quality problems, or inadequate production processes, etc., to provide a basis for taking targeted quality improvement measures.

(III) Report writing and decision-making suggestions

Write a detailed test report, which should include the purpose of the test, test methods, test results, data analysis, quality evaluation, and problems and suggestions. The test report should present the entire test process and results in an objective, accurate and clear manner, providing comprehensive and accurate product quality information for international wholesale buyers. Based on the test results, provide buyers with decision-making recommendations on whether to purchase this batch of adjustable dumbbells, and propose specific improvement directions and requirements for the problems found, to help suppliers improve product quality and achieve win-win cooperation.

In short, systematic durability testing of adjustable dumbbells is a key link to ensure product quality and meet market demand. Through the detailed testing and analysis of the above key steps, buyers can fully and deeply understand the durability of the product, so as to make wise purchasing decisions, provide the market with high-quality and reliable adjustable dumbbell products, and promote the healthy and stable development of the fitness equipment industry.