Adjustable Dumbbell Adjustment Performance Test

Adjustable Dumbbell Adjustment Performance Test

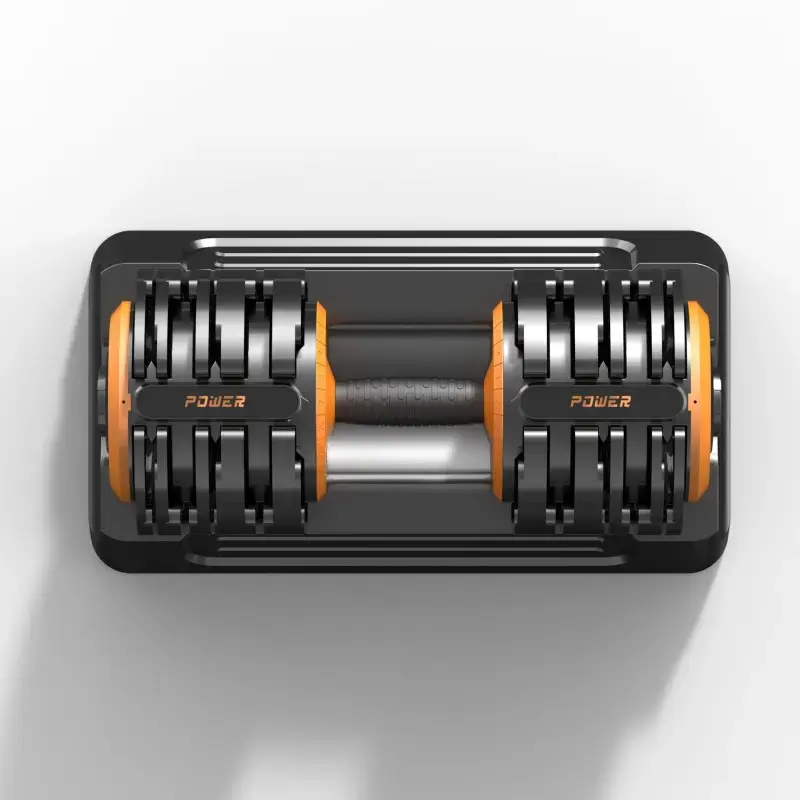

In today's fitness equipment market, Adjustable Dumbbells are favored by more and more fitness enthusiasts because of their convenience and versatility. For international wholesale buyers, it is crucial to ensure that the adjustable dumbbells they purchase have excellent adjustment performance. This article will delve into the specific aspects of the adjustable dumbbell adjustment performance test to help buyers fully understand the product performance and make wise purchasing decisions.

1. The Importance of Adjustment Performance Test

The core advantage of adjustable dumbbells is that they can quickly adjust the weight according to the user's training needs. This feature not only improves the flexibility of training, but also reduces the number of dumbbells that users need to buy and store. However, the quality of adjustment performance directly affects the user experience and product safety. If the adjustment mechanism is not reliable or the operation is complicated, it may cause users to encounter difficulties during use, or even cause safety accidents.

For international wholesale buyers, purchasing high-quality adjustable dumbbells can not only improve customer satisfaction, but also enhance market competitiveness. Therefore, comprehensive testing of the adjustment performance of adjustable dumbbells is a key step to ensure product quality.

2. Specific aspects of the adjustable dumbbell adjustment performance test

(I) Weight adjustment range and accuracy test

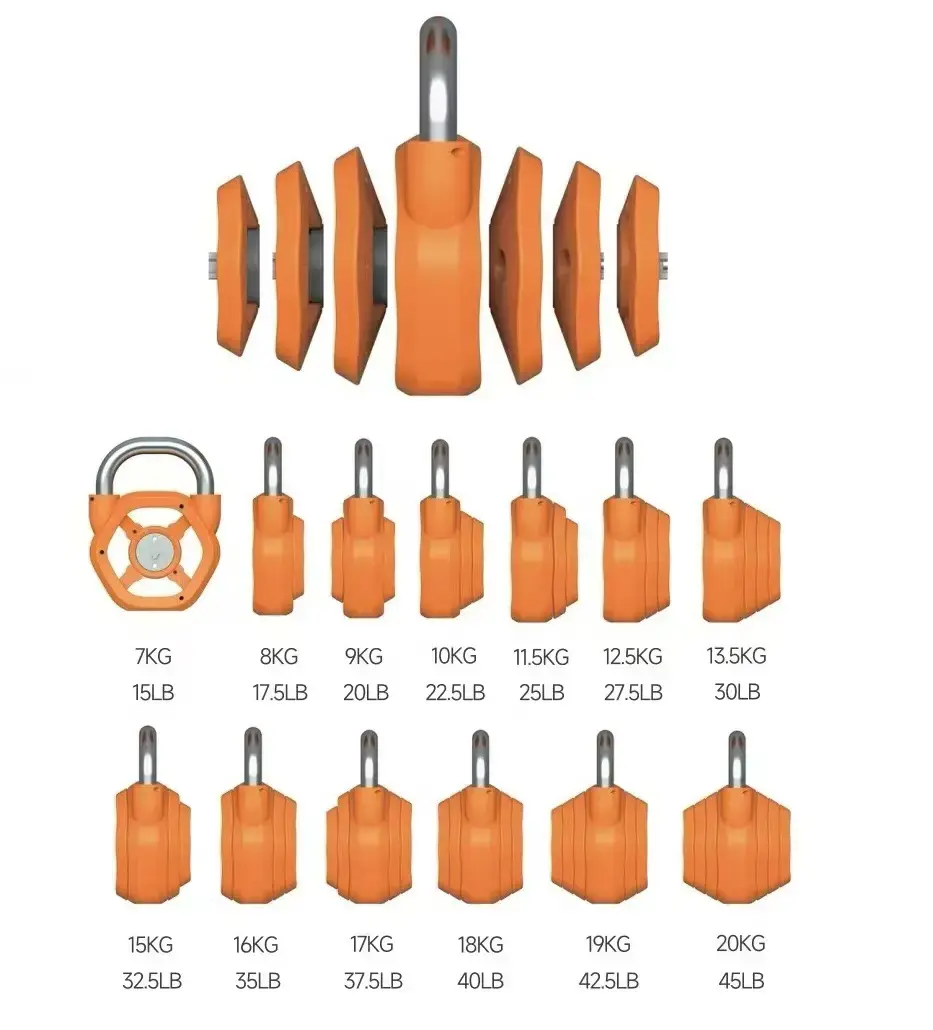

Weight adjustment range

Test purpose: Verify whether the weight adjustment range of the dumbbell is consistent with the description in the product manual. For example, an adjustable dumbbell claims that its weight can be adjusted between 5 pounds and 50 pounds. The test needs to confirm whether this range is accurate.

Test method: Use a high-precision electronic scale to weigh the weight of the dumbbell at different adjustment positions. Starting from the minimum weight setting, gradually increase the weight and record the actual weight after each adjustment. Ensure that the test covers the entire weight adjustment range.

Qualification standard: The actual weight should be consistent with the product's nominal weight, and the allowable error range is usually no more than ±1%.

Weight adjustment accuracy

Test purpose: Evaluate the accuracy of the weight change of the dumbbell during the adjustment process. For example, when the user adjusts the dumbbell from 10 pounds to 12 pounds, whether the actual weight can accurately reach the target value.

Test method: Select multiple weight adjustment points and use a high-precision electronic scale to measure the deviation between the actual weight and the target weight. Repeat the measurement multiple times to ensure the reliability of the results.

Qualification standard: The weight adjustment accuracy should be within ±0.5 pounds (or ±0.25 kilograms).

(II) Ease of adjustment operation test

Ease of use of adjustment mechanism

Test purpose: Evaluate the difficulty of users in adjusting the weight of dumbbells. A good adjustment mechanism should be simple and easy to understand, without complicated operation steps.

Test method: Invite users of different ages and fitness experience to conduct actual operation tests. Record the time required for users to complete a weight adjustment and observe whether users encounter difficulties during the operation.

Qualification standard: Most users should complete the weight adjustment operation within 10 seconds and can operate correctly without looking at the manual.

Responsiveness of adjustment knobs or buttons

Test purpose: Ensure that the adjustment knobs or buttons can respond quickly to user instructions when operated. For example, when the user turns the knob, the weight of the dumbbell should change immediately.

Test method: Turn the adjustment knob or press the button quickly several times and observe the response time of the dumbbell weight change. Use a high-speed camera to record the operation process for accurate analysis.

Qualification standard: The response time of weight change should not exceed 2 seconds.

(III) Reliability test of the adjustment locking mechanism

Stability of the locking mechanism

Test purpose: To verify whether the locking mechanism can firmly fix the weight plate after the dumbbell is adjusted to a specific weight to prevent it from loosening during use.

Test method: Adjust the dumbbell to different weight settings and then perform multiple repetitions of weightlifting. Observe whether the weight plate is loose or shifted.

Qualification standard: Under normal use conditions, the weight plate should always remain fixed without loosening or shifting.

Safety of the locking mechanism

Test purpose: To ensure that the locking mechanism can reliably prevent the weight plate from falling off under any circumstances to avoid harm to the user.

Test method: Perform extreme tests on the locking mechanism, such as checking whether the locking mechanism can still work properly under conditions beyond the normal weight range or under severe vibration.

Qualification standard: Even under extreme conditions, the locking mechanism should be able to firmly fix the weight plate to ensure safe use.

(IV) Durability test of adjustment performance

Adjustment performance after long-term use

Test purpose: To evaluate whether the adjustment performance of the dumbbell will decrease after long-term use. For example, will an adjustment knob become loose due to wear, or will a locking mechanism fail?

Test method: The dumbbells are subjected to accelerated durability testing to simulate long-term use. For example, the weight adjustment operation is performed thousands of times in succession, and then the adjustment performance is checked to see if it changes.