Adjustable dumbbell electroplating process

Adjustable Dumbbell electroplating process: the key to creating high-quality fitness equipment

I. Introduction

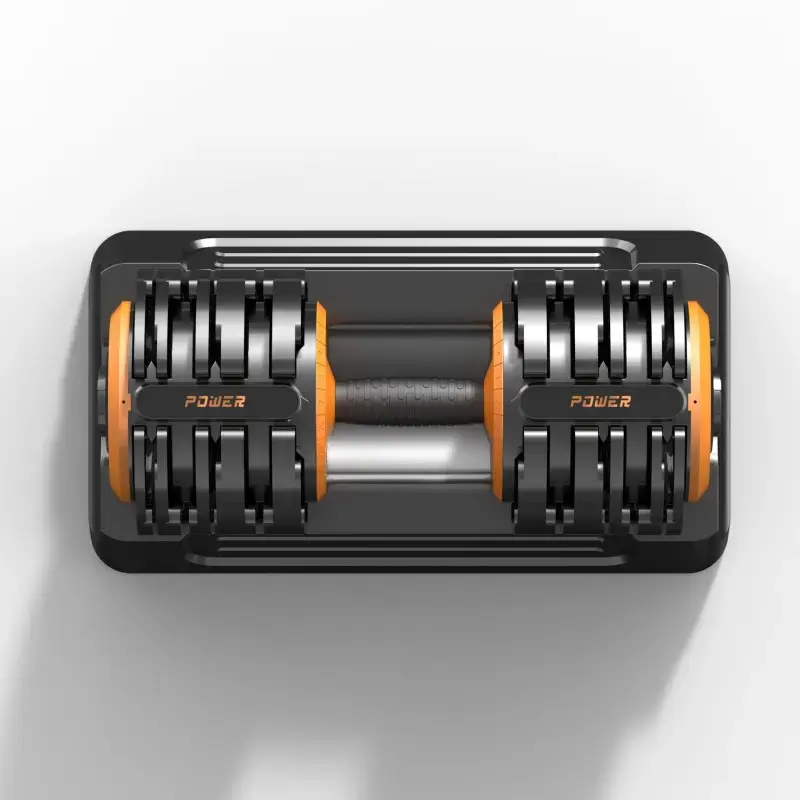

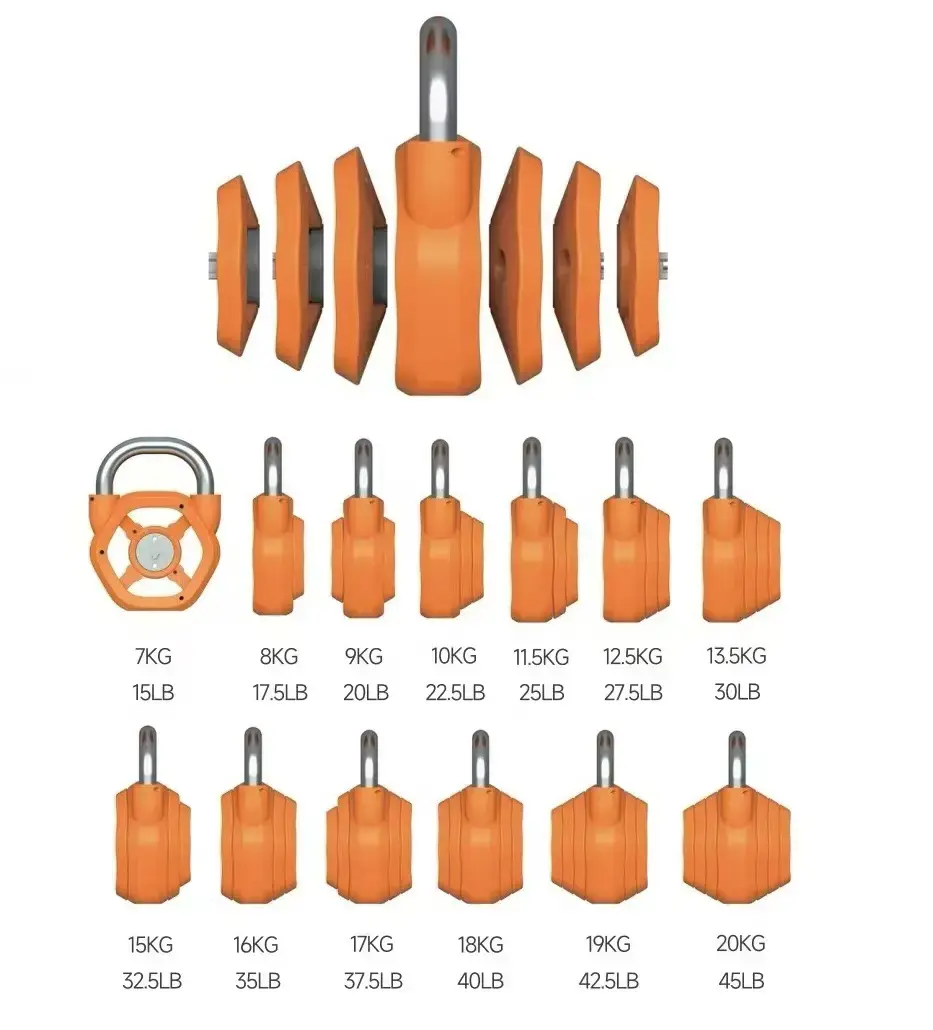

In today's global fitness equipment market, adjustable dumbbells are favored by international wholesale buyers for their flexibility and efficiency. As an important link in the manufacture of Adjustable Dumbbells, electroplating not only improves the appearance and texture of the product, but also plays a key role in durability, corrosion resistance and service life.

2. Overview of adjustable dumbbell electroplating process

(I) Definition of electroplating process

Electroplating is a surface treatment technology that deposits a thin layer of metal film on the metal surface through electrolysis. For adjustable dumbbells, electroplating is usually used for the metal parts of dumbbells, such as bells and handles, to enhance their wear resistance, corrosion resistance and aesthetics.

(II) Origin and development of electroplating process

Electroplating technology can be traced back to the early 19th century and gradually matured with the development of electrochemical theory. In the field of fitness equipment, the application of electroplating technology began in the mid-20th century. As people's requirements for the durability and aesthetics of fitness equipment increased, electroplating technology gradually became one of the standard processes for the manufacture of high-end fitness equipment.

3. Advantages of electroplating process for adjustable dumbbells

(i) Enhanced durability

The electroplating layer can significantly improve the hardness and wear resistance of dumbbell metal parts. For example, the electroplated dumbbell handles and plates can resist scratches and wear and maintain a bright and new surface during frequent use and high-intensity training.

(ii) Improved corrosion resistance

The electroplating layer can effectively prevent metal parts from contacting with moisture and oxygen in the air, thereby reducing the possibility of oxidation and corrosion. This is especially important for adjustable dumbbells because they are often used in humid environments (such as gyms), and the electroplating layer can extend the service life of the product.

(iii) Improved appearance texture

The electroplating process can provide dumbbells with a variety of metallic lusters, such as chrome, nickel, copper, etc., making the product look more exquisite and high-end. This appearance advantage not only enhances the market competitiveness of the product, but also meets the aesthetic needs of consumers for high-quality fitness equipment.

(iv) Environmental protection and safety

The modern electroplating process uses environmentally friendly materials and advanced processing technology to reduce the emission of harmful substances and meet international environmental standards. At the same time, the smooth surface of the electroplating layer also reduces the possibility of bacterial growth and improves the safety of the product.

4. Adjustable dumbbell electroplating process

(I) Pretreatment

Before electroplating, the metal parts of the dumbbell need to undergo strict pretreatment, including degreasing, rust removal, pickling and other steps. These steps can remove oil, rust and impurities on the metal surface and ensure that the electroplating layer can be evenly attached to the metal surface.

(II) Electroplating process

The electroplating process is carried out in an electrolytic cell, with the metal parts of the dumbbell as the cathode and the electroplating material as the anode. Through electrolysis, metal ions are deposited on the surface of the dumbbell parts to form a uniform metal film. The thickness and composition of the electroplating layer can be adjusted as needed to meet different performance requirements.

(III) Post-treatment

After electroplating, the dumbbell parts need to undergo post-treatment, including cleaning, drying and quality inspection. These steps can ensure the quality and stability of the electroplating layer and remove residual electrolyte on the surface.

5. Quality control of adjustable dumbbell electroplating process

(I) Electroplating layer thickness

The thickness of the electroplating layer is an important factor affecting product quality. Generally speaking, the thickness of the electroplating layer is between 5-25 microns, and the specific thickness depends on the product's usage requirements and cost considerations. Thicker electroplating layers can provide better wear resistance and corrosion resistance, but the cost will also increase accordingly.

(ii) Uniformity of electroplating layer

The uniformity of the electroplating layer directly affects the appearance and performance of the product. A high-quality electroplating process can ensure that the electroplating layer is evenly distributed on the metal surface without defects such as missing plating, peeling, and blistering.

(iii) Adhesion test

Adhesion is an indicator of the bonding strength between the electroplating layer and the metal substrate. Through the adhesion test, it can be ensured that the electroplating layer will not fall off during normal use and high-intensity training.

6. Market application of adjustable dumbbell electroplating process

(i) International market demand

In the global fitness equipment market, electroplated adjustable dumbbells are widely welcomed for their high quality and durability. Especially in developed countries such as Europe and the United States, consumers have high requirements for the quality and appearance of fitness equipment, and adjustable dumbbells with electroplating process can meet these market demands.

(II) Competitive advantages

Adjustable dumbbells with electroplating technology have obvious advantages in market competition. Their durability and aesthetics make them stand out in the market and attract more international wholesale buyers. In addition, adjustable dumbbells with electroplating technology can also be customized according to customer needs, further enhancing the market competitiveness of the product.

7. Purchasing Guide for Electroplating Technology of Adjustable Dumbbells

(I) Choose reliable suppliers

When choosing electroplated adjustable dumbbells, buyers should give priority to suppliers with good reputation and rich experience. Reliable suppliers can provide high-quality products and perfect after-sales service.

(II) Pay attention to product quality standards

Buyers should ensure that the purchased electroplated adjustable dumbbells meet international quality standards, such as ISO 9001. These standards can guarantee the quality and safety of the products.

(III) Consider cost and benefit

Although the cost of adjustable dumbbells with electroplating technology is relatively high, their durability and aesthetics can bring higher added value. Buyers should consider cost and benefit comprehensively when purchasing and choose products with high cost performance.

(IV) Customized service

Many suppliers provide customized services. Buyers can customize the color, thickness and pattern of the electroplating layer according to their market needs and customer preferences.

8. Future development trend of adjustable dumbbell electroplating process

(I) Environmentally friendly electroplating technology

With the enhancement of environmental awareness, the electroplating process will pay more attention to environmental protection in the future. The use of environmentally friendly materials and low-energy consumption processes will become the development direction of electroplating technology.

(II) Intelligent electroplating process

Intelligent electroplating technology will improve the accuracy and efficiency of the electroplating process through automation and information technology. This can not only improve product quality, but also reduce production costs.

(III) Multifunctional electroplating layer

The electroplating layer in the future will not only have wear-resistant and corrosion-resistant functions, but also integrate multiple functions such as antibacterial and self-cleaning to further enhance the added value of the product.

9. Conclusion

The adjustable dumbbell electroplating process is a key technology to improve the quality and market competitiveness of fitness equipment. By deeply understanding the principles, advantages, process flow and quality control points of the electroplating process,