Adjustable dumbbells’ adjustment performance and stability test

Adjustable Dumbbells’ adjustment performance and stability test

In the fitness equipment market, adjustable dumbbells are widely welcomed for their convenience and versatility. For international wholesale buyers, it is crucial to understand the adjustment performance and stability of adjustable dumbbells. This is not only related to the quality of the product, but also directly affects the consumer’s experience and safety. This article will explore in depth the test methods, standards and practical applications of the adjustment performance and stability of adjustable dumbbells to help wholesale buyers better select and evaluate products.

I. Adjustable dumbbells’ adjustment performance test

(I) Adjustment principles and methods

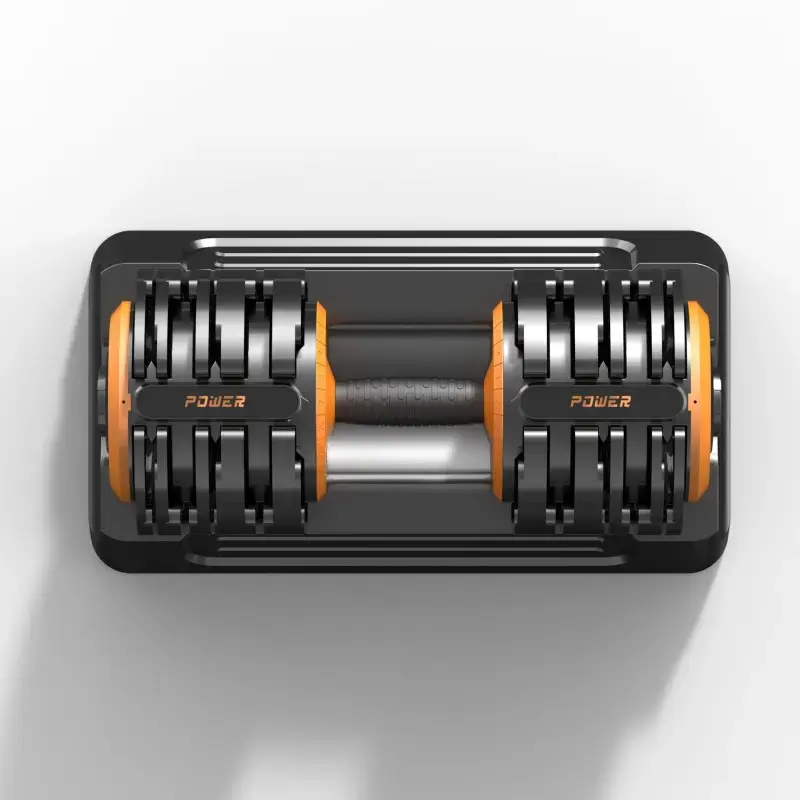

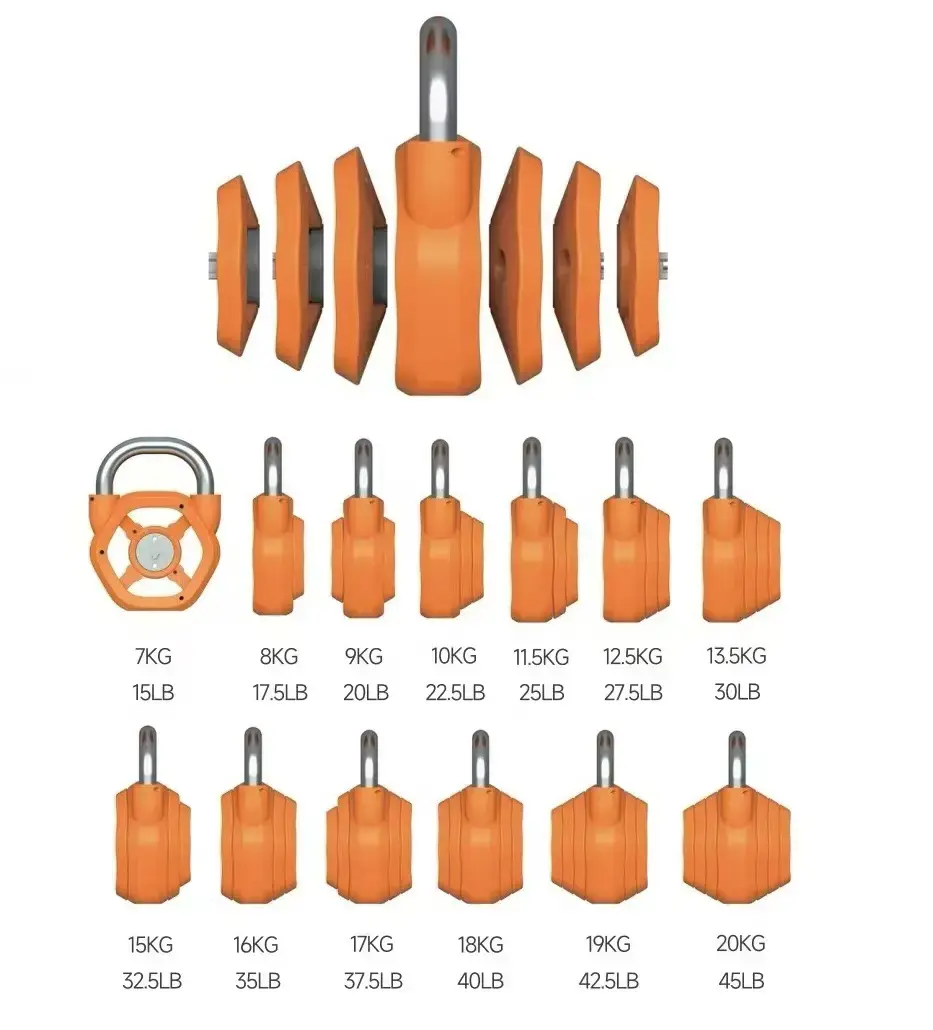

The adjustment methods of adjustable dumbbells are mainly divided into external adjustment and internal adjustment. The external adjustment method clamps the dumbbell pieces by rotating the irregular keel frame on the grip to achieve weight replacement; the internal adjustment method clamps the dumbbell pieces by telescoping the screw inside the handle. Different adjustment methods have their own advantages and disadvantages in terms of service life, weight counterweight and safety. For example, external adjustment dumbbells with metal keel frames are usually safer and more durable, while internal adjustment dumbbells may affect their service life due to the wear of the plastic connecting wheel.

(II) Test methods for adjustment performance

Adjustment speed test: measure the adjustment time from minimum weight to maximum weight. Quick adjustment is one of the important selling points of adjustable dumbbells, so testing the adjustment speed can evaluate the convenience of the product.

Adjustment accuracy test: check whether the actual weight of the dumbbell at different weight settings is consistent with the nominal weight. This can be measured by a high-precision electronic scale to ensure that the adjustment mechanism can accurately select the weight.

Repeated adjustment test: simulate the scenario of users frequently adjusting the weight, and test the wear and functional stability of the adjustment mechanism after multiple operations.

(III) International standards and certification

In the international market, the adjustment performance of adjustable dumbbells needs to meet relevant safety and quality standards. For example, the ISO 20957 standard covers the safety requirements and test methods for fixed strength training equipment. When selecting products, wholesale buyers should ensure that they meet these standards to avoid potential legal risks and quality issues.

2. Stability test of adjustable dumbbells

(I) Importance of stability

Stability is one of the key performance indicators of adjustable dumbbells. Unstable dumbbells may cause users to lose balance during use or even cause injuries. Therefore, rigorous testing of the stability of adjustable dumbbells is a necessary step to ensure product safety and reliability.

(II) Stability test method

Static stability test: Place the dumbbell on a horizontal plane and check its balance under different weight configurations. You can use an inclined platform to simulate different tilt angles to observe whether the dumbbell will tip over.

Dynamic stability test: Simulate the user's actual sports scenes in use, such as lifting, lowering and rotating the dumbbell. Use a high-speed camera to record the posture changes of the dumbbell during exercise and analyze its stability.

Load stability test: Perform a stability test under the maximum load of the dumbbell to ensure that it can remain stable under extreme conditions.

(III) Stability test standards

Stability testing needs to follow internationally accepted standards and specifications. For example, the ISO 20957 standard requires that all fixed strength training equipment must pass stability testing to ensure its safety in various use environments. Wholesale buyers should require suppliers to provide test reports and certification certificates that meet these standards.

3. Practical application and case analysis

(I) User feedback and market trends

According to market research, users have high expectations for the adjustment performance and stability of adjustable dumbbells. Fast and accurate adjustment functions and stable use experience are the main reasons why users choose adjustable dumbbells. Wholesale buyers can analyze user feedback to understand changes in market demand and choose products that are more in line with market trends.

(II) Success Case Analysis

Some well-known brands have successfully launched high-performance adjustable dumbbell products through strict testing and quality control. For example, AtivaFit's adjustable dumbbells use a steel sheet keel frame, which not only has a fast adjustment speed, but also has high stability and durability. These successful cases provide valuable experience and reference for wholesale buyers.

4. Conclusion and Suggestions

The adjustment performance and stability of adjustable dumbbells are important components of their core competitiveness. Through scientific testing methods and strict international standard certification, wholesale buyers can better evaluate the quality and safety of products. When choosing adjustable dumbbells, wholesale buyers are advised to pay attention to the following points:

Choose products that meet international standards: Make sure that the product has passed the test of relevant standards such as ISO 20957.

Pay attention to user feedback: Understand market trends and user needs, and choose products with fast adjustment speed and high stability.

Conduct field testing: Before purchasing, conduct actual regulatory performance and stability tests on the product to ensure it meets expectations.