Detailed explanation of the surface treatment process of adjustable dumbbells and wholesale purchasing guide

Adjustable Dumbbells: Detailed explanation of surface treatment process and wholesale purchasing guide

Introduction

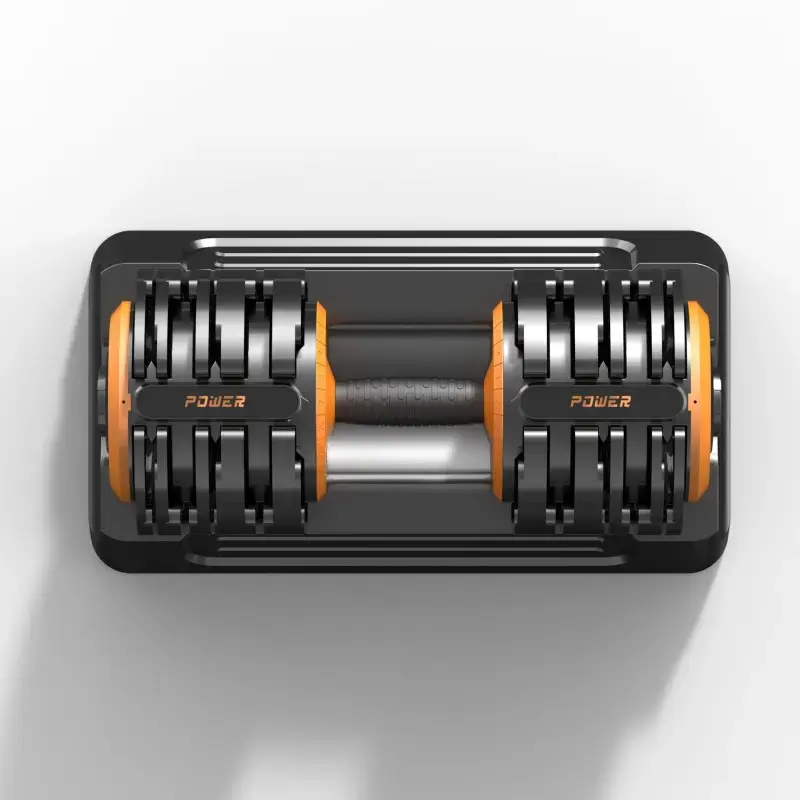

Driven by the global fitness craze, the market demand for adjustable dumbbells as efficient and convenient strength training equipment continues to rise. It is predicted that the global dumbbell market will reach US$6.12 billion by 2031, with a compound annual growth rate of 6.5% from 2024 to 2031. For international wholesale buyers, it is crucial to have a deep understanding of the surface treatment process of adjustable dumbbells, which not only affects product quality and service life, but also affects market competitiveness and customer satisfaction. This article will explore the surface treatment process of adjustable dumbbells in depth and provide a comprehensive wholesale purchasing guide.

I. Overview of the surface treatment process of adjustable dumbbells

(I) The importance of surface treatment process

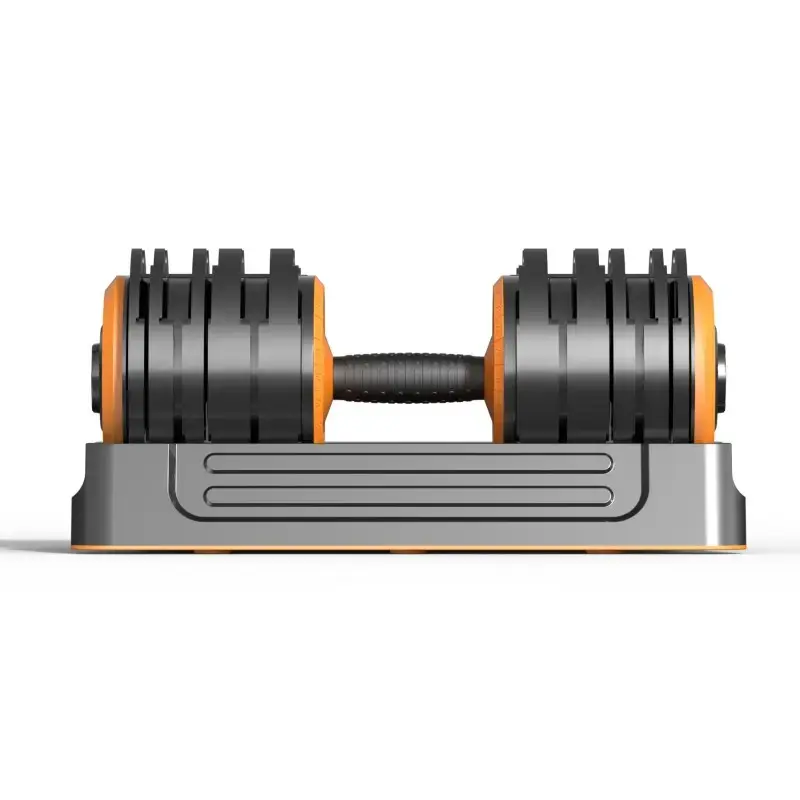

Adjustable dumbbells are affected by multiple factors such as friction, sweat, and heavy pressure during use. Strict surface treatment process can effectively improve the wear resistance, corrosion resistance and anti-aging performance of dumbbells, extend the service life of the product, and at the same time enhance its appearance and attractiveness, and increase the added value of the product. For example, the surface of the finely processed dumbbell is smooth and delicate, which is not only comfortable to the touch, but also reduces the wear on the user's hand skin.

(II) Common surface treatment processes

Electroplating process

Electroplating is one of the most commonly used surface treatment methods for adjustable dumbbells. Its principle is to plate a layer of metal film, such as zinc, nickel, chromium, etc., on the surface of the dumbbell through electrolysis. The electroplating layer has good corrosion resistance and decorative properties, which can prevent the dumbbell from rusting and give it a bright appearance. For example, the surface of chrome-plated dumbbells is as bright as a mirror, with a strong metallic texture, which can enhance the grade of the product.

Spraying process

The spraying process is to evenly apply a special coating on the surface of the dumbbell through a spraying device to form a protective film. This process can achieve a rich color selection to meet the personalized needs of different consumers. High-quality spraying materials have good adhesion and wear resistance, which can ensure that the surface color of the dumbbell remains bright and new after long-term use. For example, some dumbbells use powder spraying technology, the coating thickness is uniform, not easy to fall off, and has good impact resistance.

Oxidation process

For adjustable dumbbells made of aluminum alloy, oxidation treatment is an effective surface treatment method. Through chemical reactions such as anodic oxidation or cathodic oxidation, an oxide film is formed on the surface of the aluminum alloy. This oxide film can not only improve the hardness and wear resistance of the aluminum alloy, but also enhance its corrosion resistance. The surface of the aluminum alloy dumbbell after oxidation treatment presents a unique metallic color and texture, with good visual effects.

2. Strict process of adjustable dumbbell surface treatment process

(I) Electroplating process

Pretreatment

Degreasing: Use alkaline degreasing agent to remove oil, grease and other impurities on the surface of the dumbbell. Soak the dumbbell in the degreasing tank, emulsify or saponify the oil through chemical reaction, and then remove the residual degreasing agent on the surface by water washing. The degreasing process is usually carried out at a temperature of 50℃ - 70℃ for 10 - 20 minutes.

Pickling: There may be rust or scale on the surface of the degreased dumbbell, which needs to be pickled. Immerse the dumbbell in the pickling tank, and the acid reacts chemically with the rust or scale to dissolve and remove it. Commonly used pickling solutions include sulfuric acid, hydrochloric acid, etc. The pickling time is generally 5-15 minutes, and the temperature is controlled at 30℃-50℃. After pickling, it is also necessary to wash it with water to remove the acid remaining on the surface.

Electroplating

Pre-plating: In order to improve the bonding strength between the plating and the base metal, pre-plating is usually carried out first. The pre-plating layer generally uses a thinner metal layer, such as zinc or nickel. The dumbbell is used as the cathode, and the metal anode (such as zinc anode or nickel anode) is installed in the electroplating tank. After power is turned on, the metal ions are reduced and deposited on the cathode surface to form a pre-plating layer. Parameters such as current density, voltage and time of pre-plating need to be strictly controlled to ensure the uniformity and density of the plating layer.

Main plating: On the basis of the pre-plating, the main plating layer is electroplated. The metal material of the main plating layer is selected according to the performance requirements and decorative effects of the product. For example, chromium plating has good wear resistance and decorative properties. During the electroplating process, the composition, temperature, current density and other parameters of the electroplating solution need to be precisely controlled to ensure the quality of the main coating. For example, the temperature of the chromate plating solution is usually controlled at 50℃ - 60℃, the current density is 20 - 40A/dm², and the electroplating time is determined according to the required coating thickness, generally between 30 - 60 minutes.

Post-treatment

Passivation treatment: After the electroplating is completed, the coating is passivated to improve the corrosion resistance of the coating. The passivation treatment is to immerse the dumbbell in the passivation solution to form a dense passivation film on the surface of the coating. The composition and treatment time of the passivation solution depend on the material of the coating, and the general treatment time is 5 - 15 minutes.

Drying: Dry the passivated dumbbell to remove moisture on the surface and prevent water stains from affecting the quality of the coating. The drying temperature is generally 60℃ - 80℃, and the time is 10 - 20 minutes.

(II) Spraying process

Surface pretreatment

Polishing: Polish the surface of the dumbbell to remove burrs, scratches and other defects on the surface to make the surface smooth and flat. Mechanical polishing or manual polishing can be used. Choose the appropriate sandpaper or polishing tool according to the material and surface condition of the dumbbell. After polishing, wipe the surface with a clean rag to remove dust and grinding debris.

Degreasing and rust removal: Use chemical degreasing agents or rust removers to remove oil and rust on the surface of the dumbbell. Soak the dumbbell in degreasing and rust removal liquid for 10-20 minutes, and then rinse with clean water. The surface after degreasing and rust removal should be kept dry for subsequent spraying operations.

Spraying

Coating selection: Choose the appropriate coating according to the use requirements and appearance design of the adjustable dumbbell. The coating should have good adhesion, wear resistance, corrosion resistance and decorative properties. Common types of coatings include epoxy resin coatings, polyester coatings, acrylic coatings, etc. For example, epoxy resin coating has strong adhesion and good chemical corrosion resistance, which is suitable for dumbbells with high corrosion resistance requirements; polyester coating has good gloss retention and color retention, and can provide a variety of color options.

Spraying equipment and parameter settings: Use professional spraying equipment, such as an electrostatic sprayer or spray gun, to spray the paint evenly on the surface of the dumbbell. The parameters of the spraying equipment need to be adjusted according to the characteristics of the paint and the shape of the dumbbell, including spraying pressure, nozzle diameter, spray shape, etc. When spraying, the distance between the spray gun and the surface of the dumbbell should be kept moderate, generally 15-25 cm, to ensure the uniformity of the coating. The thickness of the spraying is generally controlled at 50-100μm. According to product requirements, multiple spraying can be carried out, and proper drying is required after each spraying.

Curing: After spraying, put the dumbbell into the oven for curing. The curing temperature and time depend on the type and performance requirements of the coating. Generally, the curing temperature of epoxy resin coating is 150℃ - 180℃, and the time is 20 - 30 minutes; the curing temperature of polyester coating is 180℃ - 200℃, and the time is 10 - 20 minutes. During the curing process, the chemical components in the coating undergo a cross-linking reaction to form a solid coating, giving the dumbbell surface good performance.

(III) Oxidation process (taking aluminum alloy dumbbells as an example)

Pretreatment

Degreasing: Similar to the degreasing process in the electroplating process, an alkaline degreasing agent is used to remove oil stains on the surface of the aluminum alloy dumbbell. After degreasing, rinse with plenty of clean water to ensure that there is no residual degreasing agent on the surface.

Alkali etching: The degreased aluminum alloy dumbbell is immersed in an alkaline etching tank. The alkaline etching solution (such as sodium hydroxide solution) reacts chemically with the aluminum alloy surface to remove surface defects such as oil stains, oxide scale and slight scratches. The alkaline etching time is generally 5-10 minutes, and the temperature is controlled at 60℃-80℃. After alkaline etching, it is necessary to wash it thoroughly with water to neutralize the alkalinity on the surface.

Neutralization treatment: In order to prevent excessive alkaline etching reaction on the surface of aluminum alloy, neutralization treatment is required. Soak the dumbbell in a neutralizing solution (such as nitric acid or sulfuric acid solution), and the neutralizing solution reacts with the alkaline substances remaining on the surface to make the surface neutral. The neutralization treatment time is generally 1-3 minutes, and then rinse it with water.

Oxidation treatment

Anodizing: The pre-treated aluminum alloy dumbbell is used as the anode, and the metal anode (such as lead plate) is used as the cathode, and placed in the oxidation tank. The oxidation tank is filled with an electrolyte, such as a sulfuric acid solution or an oxalic acid solution. After power is turned on, an oxidation reaction occurs on the aluminum alloy surface of the anode to form a dense oxide film. The voltage of anodizing is generally between 10-30V, the current density is 1-3A/dm², and the processing time is determined according to the required oxide film thickness, generally 20-60 minutes. The oxide film obtained by sulfuric acid anodizing is thicker and has good wear resistance and corrosion resistance; the oxide film obtained by oxalic acid anodizing has high hardness, but the film layer is thinner.

Sealing treatment: The oxide film after anodizing needs to be sealed to improve its corrosion resistance and wear resistance. The sealing treatment methods include hot water sealing, cold sealing, etc. Hot water sealing is to immerse the oxidized dumbbell in hot water above 90℃ to seal the pores in the oxide film. Cold sealing is to immerse the dumbbell in a sealing liquid containing specific chemicals at room temperature to seal the pores through chemical reactions. The sealing treatment time is generally 10-30 minutes.

3. Quality control of the surface treatment process of adjustable dumbbells

(I) Raw material quality control

Metal material selection

For the electroplating process, metal materials with high purity and low impurity content are selected as the raw materials for plating, such as high-purity zinc, nickel, chromium, etc. The purity of these metal materials directly affects the quality and performance of the plating. For example, high-purity chromium can ensure that the plating has good hardness and wear resistance.

In the spraying process, the quality of the coating is crucial. Coatings that meet environmental protection standards and have stable performance should be selected, and their main components include resins, pigments, solvents and additives. High-quality coatings can provide good adhesion, weather resistance and decorative properties. For example, using imported high-performance resins as the base material of the coating can improve the comprehensive performance of the coating.

Alloy composition control

For adjustable dumbbells made of aluminum alloy, the composition ratio of the alloy needs to be strictly controlled during the production process. Different alloy compositions will affect the effect of oxidation treatment. For example, adding an appropriate amount of copper to aluminum alloy can improve its strength and wear resistance, but too high a copper content will cause the color of the oxide film to darken, affecting the appearance quality. Therefore, when producing aluminum alloy dumbbells, the composition of the alloy should be accurately controlled according to the performance requirements and surface treatment process of the product.

(II) Process parameter control

Electroplating process parameters

Electroplating solution composition: Regularly test and adjust the composition of the electroplating solution to ensure that it meets the process requirements. For example, in chromate electroplating solution, the concentration of chromate ions, the concentration of sulfate ions, and the content of catalysts need to be strictly controlled. Too low chromate ion concentration will lead to slow deposition speed and uneven thickness of the coating; too high concentration will easily cause the coating to burn and affect the quality of the coating.

Electroplating current density and voltage: According to the material, shape and size of the dumbbell, the electroplating current density and voltage should be reasonably set. Too high current density will lead to coarse crystallization and rough surface of the coating; too low current density will make the coating deposition speed too slow, affecting production efficiency. Voltage fluctuations will also affect the quality of the coating, so it is necessary to equip a stable power supply equipment to ensure voltage stability during the electroplating process.

Electroplating time: Determine the appropriate electroplating time according to the required coating thickness. If the electroplating time is too short, the coating thickness is insufficient and cannot meet the product performance requirements; if the electroplating time is too long, it will cause a waste of resources and may affect the bonding strength between the coating and the base metal.

Spraying process parameters

Paint viscosity: Paint viscosity is one of the important factors affecting the quality of spraying. If the coating viscosity is too high, it will cause defects such as sagging and orange peel during spraying; if the viscosity is too low, the coating will be too thin, affecting the performance of the coating. Therefore, before spraying, the viscosity of the coating needs to be adjusted according to the characteristics of the coating and the requirements of the spraying equipment. Generally, the viscosity of the coating can be adjusted by adding an appropriate amount of diluent, and the viscometer is used for measurement and control.

Spraying pressure and nozzle diameter: The spraying pressure and nozzle diameter directly affect the atomization effect and spraying range of the coating. If the spraying pressure is too high, the atomized particles of the coating will be too fine, which is prone to uneven electrostatic adsorption; if the pressure is too low, the coating will be poorly atomized and the coating will be uneven. The selection of nozzle diameter should be adjusted according to the shape and size of the dumbbell to ensure that the coating can be evenly covered on the surface of the dumbbell.

Curing temperature and time: Strictly control the curing temperature and time to ensure that the coating can be fully cured and achieve the expected performance indicators. If the curing temperature is too high or the time is too long, the coating will become brittle and affect its adhesion and wear resistance; if the curing temperature is too low or the time is too short, the coating will not be completely cured and the performance will not meet the requirements. During the curing process, the curing conditions of the coating, such as hardness, adhesion, etc., should be checked regularly to determine the optimal curing process parameters.

Oxidation process parameters

Electrolyte composition and temperature: During the anodizing process, the composition and temperature of the electrolyte have an important influence on the quality of the oxide film. For example, in sulfuric acid anodizing, the concentration of sulfuric acid, the content of additives, and the temperature of the electrolyte need to be strictly controlled. Too high a sulfuric acid concentration will cause the oxide film to dissolve faster and the film layer to become thinner; too low a concentration will cause the oxide film to grow slowly and be inefficient. Too high an electrolyte temperature will increase the porosity of the oxide film and affect its corrosion resistance; too low a temperature will reduce the oxidation reaction rate and prolong the processing time.

Voltage and current density: According to the material of aluminum alloy and the requirements of oxide film, the voltage and current density of anodizing should be reasonably set. The size of voltage and current density directly affects the thickness and hardness of oxide film. If the voltage is too high, the growth rate of oxide film will be too fast, but it is easy to burn, resulting in the decline of film quality; if the voltage is too low, the growth of oxide film will be slow, affecting production efficiency. If the current density is too large, the aluminum alloy matrix will be locally overheated, resulting in uneven oxide film; if the current density is too small, it will not be possible to obtain sufficient oxide film thickness.

Oxidation time: The length of oxidation time determines the thickness of oxide film. If the oxidation time is too short, the thickness of oxide film is insufficient and cannot meet the protection and decoration requirements of the product; if the oxidation time is too long, it will cause waste of resources, and may increase the porosity of oxide film and affect its performance. Therefore, it is necessary to determine the optimal oxidation time according to the requirements of the product and process conditions.

(III) Quality inspection and testing

Appearance inspection

Visual inspection: Visually inspect the surface of the adjustable dumbbell to observe whether there are defects such as scratches, bubbles, pitting, uneven color, etc. For example, in electroplating products, the surface should be bright and smooth, without obvious plating peeling, burning and other phenomena; the surface of spray-coated products should be bright in color, uniform in coating, without sagging, orange peel and other problems; the surface of oxidized products should have no obvious defects such as uneven oxide film and spots.

Gloss measurement: Use a gloss meter to measure the gloss of the dumbbell surface to evaluate its appearance quality. Different surface treatment processes and product requirements have different standards for gloss. For example, high-gloss electroplating products usually require a gloss of more than 80%, while the gloss of matte-treated spray-coated products may be between 20% and 50%. By measuring the gloss, it can be determined whether the appearance of the product meets the design requirements and customer expectations.

Performance testing

Adhesion test: Use methods such as the cross-cut method or the pull-off method to test the adhesion of the coating or plating to the base metal. Draw a grid of a certain size on the surface of the dumbbell or paste a tensile test block, and then apply tension through special equipment to observe whether the coating or plating falls off and the degree of shedding. A coating or plating with strong adhesion can firmly adhere to the base metal, ensuring that the product will not have quality failures due to adhesion problems during use.

Wear resistance test: Use a wear tester to test the wear resistance of the dumbbell surface to simulate the friction during actual use. Fix the dumbbell on the test machine, rub it with the specified friction material under a certain pressure and number of frictions, and then measure the depth of surface wear or mass loss. For example, in the wear resistance test of the electroplated chrome layer, the test is carried out in accordance with national standards or industry standards, and its wear resistance is required to reach a certain index to ensure the service life of the product.

Corrosion resistance test: Test the corrosion resistance of the dumbbell by methods such as salt spray test. Place the dumbbell in a salt spray test chamber to simulate the corrosion conditions in the marine climate or industrial environment. After a certain period of testing, observe whether rust, corrosion and other phenomena appear on the surface. For example, the salt spray test time of the electroplated zinc layer is generally 24-72 hours, and the specific test time is determined according to the requirements of the product. Through corrosion resistance testing, the reliability and durability of the product in different environments can be evaluated.

Dimension and weight detection

Dimension measurement: Use measuring tools (such as vernier calipers, micrometers, etc.) to measure the dimensions of the dumbbells, including length, width, height, and handle diameter. Ensure that the dimensional accuracy meets the requirements of the design drawings and product standards. For adjustable dumbbells, it is also necessary to check whether the dimensions of each part after adjustment are accurate to ensure that they can be assembled and used normally.

Weight detection: Use a high-precision electronic scale or balance to measure the weight of the dumbbell to ensure that the weight meets the specified tolerance range. For fitness equipment, weight accuracy is crucial because it directly affects the training effect and safety of the user. For example, when the adjustable dumbbell is adjusted to different weight levels, the weight deviation should be controlled within ±5% to meet the user's precise training needs.

4. Comparative analysis of adjustable dumbbell surface treatment processes

(I) Comparison of electroplating process with other processes

Performance comparison

Wear resistance: The electroplated chrome layer has excellent wear resistance and is suitable for high-intensity and high-frequency adjustable dumbbells. In contrast, the wear resistance of the spray coating is relatively poor, but after reasonable selection of coatings and optimization of processes, it can also meet general use requirements; the wear resistance of the oxide film is between that of the electroplated layer and the spray coating. The oxide film obtained by sulfuric acid anodization has good wear resistance and can withstand certain friction and wear.

Corrosion resistance: Electroplating layers (such as zinc plating, nickel plating, etc.) can provide good corrosion resistance, especially the electroplating layer after passivation treatment, the corrosion resistance is further improved. The corrosion resistance of the spray coating depends on the quality of the coating and the thickness of the coating. High-quality spray coatings can effectively block the invasion of external corrosive media; the oxide film can improve the corrosion resistance of aluminum alloys, but in harsh corrosive environments, its corrosion resistance may not be as good as that of the electroplating layer.

Hardness and strength: The hardness of the electroplating layer is relatively high, especially the chromium plating layer, which has a high surface hardness and can withstand greater impact and pressure. The hardness of the spray coating is generally low, but in some special coating formulas, the hardness of the coating can be improved by adding hardness additives and other methods; the hardness of the oxide film is relatively high, especially after the aluminum alloy is anodized, the surface hardness is significantly improved, and it has good wear resistance and scratch resistance.

Appearance comparison

Metal texture: The electroplating process can give the dumbbells a strong metal texture, such as the surface of chrome-plated products is as bright as a mirror, with a silvery white metallic luster, giving people a high-end and exquisite feeling. Although the spraying process can simulate the metal texture by selecting metallic pigments, the visual effect is not as real and strong as the electroplating layer; the appearance of the oxide film presents a unique metal color, such as the surface of the aluminum alloy after anodizing presents the natural color of aluminum or various colors after coloring treatment, with a simple and natural metal texture.

Color diversity: The spraying process has obvious advantages in color selection, which can achieve rich color and pattern design to meet the personalized needs of different consumers. The color of the electroplating process is relatively simple, mainly silver, nickel, chrome and other metal colors, but in some special electroplating processes, colored coatings such as bronze and black can also be obtained; the color of the oxidation process mainly depends on the thickness of the oxide film and the coloring treatment, and the color types are relatively limited, and the common ones are silver gray, gold, black, etc.

Cost comparison

Material cost: The price of metal materials (such as zinc, nickel, chromium, etc.) required for the electroplating process is relatively high, especially rare metals such as chromium, whose prices fluctuate greatly, increasing the material cost of the electroplating process. The coating cost of the spraying process varies depending on the quality and brand. Generally, the price of low-end coatings is low, while the price of high-performance and environmentally friendly coatings is relatively high; for aluminum alloy materials, the oxidation process mainly consumes electrolytes and additives in the oxidation process, and the cost is relatively low.

Equipment and energy costs: The electroplating process requires professional electroplating equipment, including electroplating tanks, power supply equipment, ventilation equipment, etc., and the equipment investment is large. In addition, a large amount of electricity and chemicals are consumed during the electroplating process, and the energy cost is high. The spraying process requires spraying equipment, baking equipment, etc., the equipment cost is moderate, and the energy consumption is mainly used for the drying and curing process of the paint; the oxidation process requires oxidation equipment, power supply equipment, etc., the equipment cost is relatively low, and the energy consumption is mainly used for the electrolysis process and hot water sealing treatment.

Labor cost: The production process of electroplating process and oxidation process is relatively complicated, requiring professional technicians to operate and monitor, and the labor cost is relatively high. The spraying process has relatively low labor costs on production lines with a high degree of automation, but there are also certain requirements for the operating skills of spray workers to ensure the quality and efficiency of spraying.

II) Comparison between spraying process and other processes

Performance comparison

Adhesion: The adhesion of the spraying process depends to a certain extent on the compatibility of the coating with the base material and the quality of the surface pretreatment. After good pretreatment and reasonable selection of coatings, the adhesion of the spray coating can reach a high level and be closely bonded to the base metal; the adhesion of the electroplated layer is usually good, but in some special cases, such as the presence of impurities such as oil stains and oxide scale on the surface of the base metal, the adhesion of the coating may decrease; the oxide film is closely bonded to the aluminum alloy base, has strong adhesion, and can be firmly attached to the base surface.

Flexibility and impact resistance: The spray coating has certain flexibility and impact resistance, and can withstand external collisions and impacts to a certain extent, and it is not easy for the coating to peel off or crack. The flexibility of the electroplated layer is relatively poor, and when it is subjected to a large impact force, the coating is prone to peeling or cracking; the oxide film has good impact resistance, but because it is generated by chemical reaction, it is closely bonded to the base and has a certain brittleness. When it is subjected to a strong impact, the film layer may break.

Appearance comparison

Surface smoothness: The surface of the electroplating layer is usually very smooth and delicate. After polishing, it can achieve a mirror effect, with good hand feel and visual effect. The surface smoothness of the spray coating depends on the leveling of the coating and the control of the spraying process. A high-quality spraying process can obtain a relatively smooth surface, but compared with the electroplating layer, it may be slightly inferior in terms of smoothness and gloss uniformity; the surface of the oxide film is relatively rough, but after appropriate post-treatment (such as polishing, rolling, etc.), its surface smoothness can be improved and the appearance quality can be improved.

Visual effect: The spraying process can achieve various special visual effects such as metallic glitter, pearlescent, frosted, etc. through different coating formulas and spraying techniques to meet consumers' personalized pursuit of product appearance. The visual effect of the electroplating process is mainly based on metallic luster, which is simple and generous, giving people a sense of professionalism and durability; the visual effect of the oxidation process is mainly based on natural metallic color and texture, with high recognition and uniqueness, suitable for consumers who pursue a simple style.

Environmental protection comparison

Environmental protection of coatings and electroplating materials: In the traditional electroplating process, the electroplating solution used contains a large amount of heavy metal ions (such as chromium, cadmium, nickel, etc.), which are very harmful to the environment and easily cause environmental pollution such as soil and water sources. With the continuous improvement of environmental protection requirements, some new environmentally friendly electroplating materials and processes have gradually been applied, but the treatment of electroplating wastewater is still an issue that needs to be focused on. Some of the coatings used in the spraying process contain volatile organic compounds (VOCs), which will be released into the air during the spraying process, causing harm to the environment and human health. However, many low-VOC or VOC-free environmentally friendly coatings have appeared on the market. By adopting water-based coatings, high-solid coatings, etc., the pollution to the environment can be effectively reduced.

Waste treatment: Waste residues, waste liquids and other wastes generated in the electroplating process need to be specially treated and recycled to avoid the spread of harmful substances. The waste generated by the spraying process mainly includes waste coatings, waste paint mist filter materials, etc. These wastes also need to be classified and recycled according to environmental protection requirements. The oxidation process generates relatively few wastes during the production process, mainly electrolyte replacement and waste residue, but they also need to be properly handled to prevent environmental pollution.

(III) Comparison of oxidation process with other processes

Performance comparison

Weather resistance: The oxide film has good weather resistance and can resist the erosion of natural environmental factors such as ultraviolet rays, wind and rain, and humidity, which is suitable for adjustable dumbbells used in outdoor environments. When the electroplating layer is exposed to the natural environment for a long time, it is easily affected by ultraviolet rays and humid air, resulting in discoloration and peeling of the coating; the weather resistance of the spray coating depends on the quality and type of the coating. High-quality outdoor coatings have good weather resistance, but compared with the oxide film, they may be slightly inferior in terms of ultraviolet resistance and aging resistance.

Conductivity and insulation: The electroplating layer has good conductivity. If special applications such as electrical connection or electromagnetic shielding of adjustable dumbbells are required, the electroplating process is a good choice. Spray coatings are generally insulating unless they are sprayed with conductive coatings; the oxide film also has certain insulation and can meet some occasions that require insulation performance.

Appearance comparison

Color stability: The color stability of the oxide film is good, and the color can remain unchanged for a long time under normal use. The color of the electroplating layer may fade or change due to environmental factors and the increase of use time, especially when the plating layer is corroded or worn, the color change will be more obvious; the color stability of the spray coating depends on the quality of the coating and the use environment. High-quality coatings can maintain color stability for a long time under normal use conditions, but when exposed to strong ultraviolet radiation or chemical erosion, the color may fade or change.

Texture effect: The surface of the oxide film can form a unique texture effect. For example, after a special oxidation process, the surface of the aluminum alloy can present a texture similar to brushed and frosted, which increases the visual layering and touch of the product. The texture effect on the surface of the electroplating layer is relatively difficult to achieve, generally with a smooth mirror or a delicate matte surface; the spraying process can simulate various texture effects, such as imitation wood grain, imitation stone grain, etc., by changing the spraying process parameters or using special coating formulas, and has a high degree of design freedom.

Cost comparison

Maintenance cost: Once the oxide film is formed, its maintenance cost is relatively low as long as strong mechanical collision and chemical corrosion are avoided during use. The electroplating layer needs to be maintained regularly during use, such as cleaning the surface, applying anti-rust oil, etc., to extend its service life, and the maintenance cost is relatively high; the spray coating also needs to be cleaned and inspected regularly. If the coating is damaged, it needs to be repaired in time, otherwise it will affect the appearance and performance of the product, and its maintenance cost is also relatively high.

Life cost: Although the electroplating process and spraying process may have high initial investment and production costs, due to their advantages in certain properties (such as wear resistance and decorativeness), they can meet the needs of specific user groups and have high added value and market competitiveness in specific market areas, thus balancing the life cost to a certain extent. The oxidation process has certain advantages in life cost, especially in outdoor applications with high requirements for product corrosion resistance and weather resistance. Its lower maintenance cost and longer service life can reduce the overall cost of use.

5. Development trend of adjustable dumbbell surface treatment process

(I) Promotion of environmentally friendly surface treatment process

With the continuous improvement of global environmental awareness, countries have paid more and more attention to environmental pollution in industrial production and formulated a series of strict environmental regulations and emission standards. In the field of adjustable dumbbell surface treatment, the promotion of environmentally friendly surface treatment process has become an inevitable trend. For example, chromium-free electroplating process has gradually been applied, using chromium-free passivation agents and plating materials to reduce or eliminate the use and emission of heavy metals such as chromium, and reduce pollution to the environment. At the same time, water-based paints and high-solid paints are increasingly used in spraying processes. These paints use water or high-solid resins as solvents, have the characteristics of low VOC emissions, and meet environmental protection requirements.

(II) Development of multifunctional composite surface treatment process

In order to meet the high performance and multi-functional requirements of adjustable dumbbells, multifunctional composite surface treatment processes are constantly developing. For example, the electroplating process is combined with the chemical conversion treatment process to form a chemical conversion film on the surface of the electroplating layer, further improving the corrosion resistance and wear resistance of the coating; or the spraying process is combined with the micro-arc oxidation process, the aluminum alloy is first micro-arc oxidized to form a dense ceramic film, and then sprayed, so that the product has good corrosion resistance and hardness, and rich colors and decorativeness. This composite process can combine the advantages of various surface treatment methods to achieve performance indicators that cannot be achieved by a single process, providing a new way to improve the performance and expand the functions of adjustable dumbbells.

(III) Application of intelligent surface treatment production lines

With the continuous development of industrial automation and intelligent technology, intelligent surface treatment production lines have been applied in the production of adjustable dumbbells. These production lines are equipped with advanced automation equipment and control systems, such as robot spraying equipment, automated electroplating production lines, intelligent oxidation treatment equipment, etc., which can realize the automation and intelligent operation of the surface treatment process. Through automated production lines, production efficiency can be improved, labor costs can be reduced, and the stability and consistency of product quality can be guaranteed. In addition, the intelligent control system can monitor various parameters in the production process in real time, such as temperature, humidity, current density, paint spraying amount, etc., and automatically adjust according to the preset process parameters to ensure that each production link meets strict quality control requirements and improve the product qualification rate.

(IV) The rise of personalized surface treatment process

With the increasingly personalized trend of the consumer market, the demand for personalized customization of adjustable dumbbells continues to grow. As a key link that affects the appearance and partial performance of products, surface treatment technology is also constantly meeting the requirements of personalized customization. For example, through a special spraying process, unique patterns, logos, color combinations, etc. can be customized for dumbbells to meet the aesthetic needs and brand identification needs of different user groups; or according to customer requirements, different surface treatment process combinations can be used to achieve differentiated product performance, such as electroplating in some areas to enhance wear resistance, and oxidation in some areas to improve corrosion resistance. This personalized surface treatment process can not only enhance the added value of the product, but also enhance customer satisfaction and loyalty, providing strong support for enterprises to expand markets and improve competitiveness.

6. Purchasing Guide for International Wholesale Buyers of Adjustable Dumbbells

(I) Finding Reliable Suppliers

Industry Exhibitions and Seminars

Participate in internationally renowned fitness equipment industry exhibitions, such as the International Health, Fitness and Sporting Goods Show (IHRSA) in the United States and the Cologne Sporting Goods Show (FISPO) in Germany. These exhibitions bring together adjustable dumbbell manufacturers and suppliers from all over the world. Buyers can communicate face-to-face with suppliers at the exhibitions to learn about product features, production processes, quality control and other aspects. At the same time, they can also view product samples on site to evaluate product quality. In addition, you can also pay attention to relevant seminars and product launches at the exhibition to grasp the latest developments and trends in the industry and provide reference for purchasing decisions.

B2B Platforms and Online Catalogs

Use professional B2B platforms, such as Alibaba International Station and eWorldTrade, on which you can search for a large amount of adjustable dumbbell supplier information. Buyers can conduct preliminary screening based on supplier reputation ratings, product reviews, transaction history and other information, and then communicate with potential suppliers online to obtain detailed information such as product catalogs, price lists, quality certifications, etc. In addition, you can also refer to some industry online directories, such as Thomasnet, Europages, etc. These directories have detailed classification and introduction of suppliers, which makes it convenient for buyers to quickly find suppliers that meet the requirements.

Industry recommendation and word of mouth

Consult peer companies, industry experts, trade associations, etc. to recommend reliable adjustable dumbbell suppliers. In the industry, other buyers' actual purchasing experience and evaluation of suppliers are very important references. Through word-of-mouth recommendations, buyers can understand the true performance of suppliers in terms of product quality, delivery time, after-sales service, etc., thereby reducing procurement risks. In addition, participating in industry forums and exchange activities and establishing connections with industry insiders are also effective ways to obtain supplier recommendation information.

(II) Evaluate the supplier's surface treatment process capabilities

Process technology level

Require suppliers to provide detailed surface treatment process flow and technical parameter descriptions to understand whether they have a strict quality control system and advanced process equipment. For example, ask the supplier about the plating solution composition control method, current density and voltage adjustment range, coating thickness detection method, etc. used in the electroplating process; for the spraying process, understand the brand and quality standards of the coating, the accuracy and automation of the spraying equipment, and the control parameters of the coating curing process; for the oxidation process, pay attention to the detection methods and results of the performance indicators such as the thickness, hardness, and corrosion resistance of the oxide film. By comparing the process technology levels of different suppliers, select suppliers with higher process capabilities.

Quality certification and test reports

Confirm whether the supplier has passed relevant international quality certifications, such as ISO 9001 quality management system certification, ISO 14001 environmental management system certification, etc. These certifications indicate that the supplier meets international standards in production management and quality control, and can ensure the quality and stability of the product. At the same time, require suppliers to provide product quality test reports issued by third-party testing agencies, especially performance test reports for surface treatment processes, such as corrosion resistance test reports, wear resistance test reports, adhesion test reports, etc. These test reports can objectively reflect the surface treatment quality of the supplier's products and help buyers make accurate evaluations.

Sample testing and verification

Request product samples from suppliers for detailed testing and verification. Test items should include appearance inspection, size and weight measurement, surface treatment performance test (such as adhesion, wear resistance, corrosion resistance, etc.), and product assembly and use performance test. During the test process, strictly follow the buyer's own quality standards or industry standards, record the test results and compare them with the quality indicators provided by the supplier. If the sample test results do not meet the requirements, communicate with the supplier in a timely manner and request improvements or re-providing samples until you are satisfied.

(III) Determine procurement needs and cooperation models

Market demand analysis

Buyers should deeply analyze the characteristics and trends of the target market's demand for adjustable dumbbells. Markets in different regions may have differences in product appearance, performance, specifications, etc. For example, in the European and American markets, consumers pay more attention to the product's appearance design and brand recognition, and have higher requirements for the decorativeness and environmental protection of the surface treatment process; while in some emerging markets, such as Southeast Asia and the Middle East, consumers may pay more attention to the cost-effectiveness and practicality of the product, and have higher requirements for the wear resistance and corrosion resistance of the surface treatment process. In addition, different sales channels (such as professional fitness equipment stores, sporting goods supermarkets, e-commerce platforms, etc.) have different product positioning and demand. Through market research, understand the demand characteristics of the target market and provide a basis for determining procurement needs.

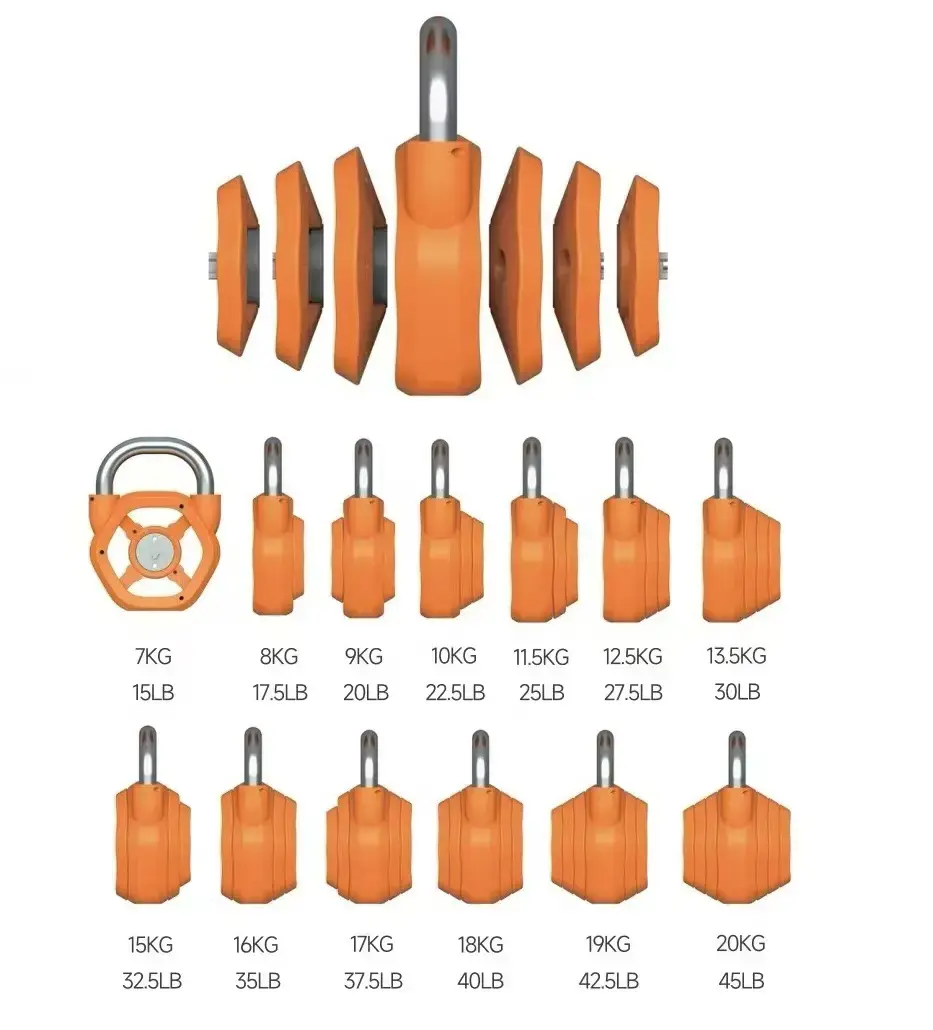

Procurement quantity and specifications

According to market forecasts and sales plans, determine the purchase quantity and specifications of adjustable dumbbells. The determination of the purchase quantity should take into account factors such as seasonal fluctuations in market demand, inventory costs, and the supplier's minimum order quantity. For example, in the peak season for fitness equipment sales (such as the beginning of the year, summer, etc.), the purchase quantity can be appropriately increased to meet market demand; while in the off-season, the purchase quantity can be reduced to reduce inventory pressure. At the same time, according to the fitness needs and usage scenarios of the target customer groups, choose the appropriate dumbbell specifications, including weight range, size, material, etc. For example, for home fitness users, you can purchase adjustable dumbbells with lighter weight and smaller volume; while for professional gym customers, you need to provide products with heavier weight and higher performance.

Cooperation model selection

Different cooperation models can be selected according to the buyer's own strength and business needs. Common cooperation models include one-time purchases, long-term cooperation agreements, OEM/ODM OEM, etc. One-time purchase is suitable for situations where market demand is unstable or the buyer has limited knowledge of suppliers. By comparing the products and prices of multiple suppliers, the most suitable supplier is selected for a single transaction. Long-term cooperation agreements are suitable for establishing stable cooperative relationships with suppliers with good reputation and stable product quality. By signing long-term contracts, the price, quality standards, delivery period and other terms of the products are determined to ensure the stability of the buyer's supply chain and cost advantages. The OEM/ODM OEM model is suitable for situations where the buyer has its own brand and product design capabilities and hopes that the supplier will produce according to the design drawings and production processes provided by it. This model can improve the differentiation and brand value of the product, but it has high requirements on the supplier's technical capabilities and quality control level.

(IV) Price negotiation and contract signing

Price composition analysis

Before negotiating prices with suppliers, buyers need to understand the price composition of adjustable dumbbells in detail. Generally speaking, the price mainly includes raw material costs, production process costs, surface treatment costs, packaging costs, transportation costs, profits and other parts. Among them, the cost of the surface treatment process accounts for a certain proportion in the price composition, and different surface treatment processes and quality requirements will lead to cost differences. For example, the price of chrome plating in the electroplating process is relatively high, and the use of high-quality imported coatings in the spraying process will also increase costs. Buyers should ask suppliers to break down the product price composition in detail and clarify the proportion of each cost so that they can negotiate in a targeted manner during price negotiations.

Price negotiation strategy

Develop a reasonable price negotiation strategy based on market research results and your own procurement needs. The following common strategies can be adopted:

Compare quotations from multiple suppliers: Invite multiple suppliers with supply capabilities to make quotations, and then conduct a detailed analysis and comparison of the quotations of each supplier, and select suppliers with reasonable prices, good quality and service as the key negotiation targets. During the negotiation process, you can show the supplier the advantageous quotations of other suppliers to encourage them to lower prices or provide more competitive conditions.

Emphasize the purchase volume and long-term cooperation potential: If the buyer has a large purchase volume or the intention of long-term cooperation, you can emphasize this point in the price negotiation and ask the supplier to give a certain price discount or preferential terms. In order to obtain stable orders and long-term cooperation opportunities, suppliers are usually willing to make certain concessions on price.

Flexible adjustment of procurement requirements: Under the premise of ensuring product quality and basic performance, buyers can flexibly adjust procurement requirements based on supplier feedback, such as appropriately relaxing some performance index requirements for surface treatment processes, adjusting product specifications or packaging methods, etc., to reduce product costs and thus achieve price reductions.

Cost analysis and negotiation: Analyze the cost structure of products with suppliers and explore the possibility of reducing costs in terms of raw material procurement, production process optimization, and surface treatment process improvement. The two parties can jointly study how to reduce product costs by optimizing supply chain management and improving production efficiency, and then negotiate a reasonable price based on the extent of cost reduction.

Contract terms After the price is agreed upon, the buyer and the supplier need to jointly enter into a detailed procurement contract. The contract terms should include product specifications, quality standards, surface treatment process requirements, prices, delivery dates, payment methods, packaging requirements, transportation methods, quality assurance periods, after-sales services, and liability for breach of contract. For special requirements for surface treatment processes, detailed technical parameters and testing methods should be clearly stated in the contract to ensure that suppliers produce in accordance with the agreed process standards. At the same time, the quality assurance period and after-sales service terms should be clearly stipulated in the contract. If the product has surface treatment quality problems (such as plating peeling, coating shedding, oxide film corrosion, etc.) during the quality assurance period, the supplier shall bear the responsibility of free repair, replacement or return. In addition, key terms such as payment method and delivery period should be reasonably agreed upon according to the actual situation of both parties and market practices to ensure the smooth progress of the transaction and the protection of the interests of the purchaser.

7. Conclusion

The surface treatment process of adjustable dumbbells plays a vital role in its production and application. Strict surface treatment process can not only improve the quality and service life of the product, but also enhance its appearance and market competitiveness. When purchasing adjustable dumbbells, international wholesale buyers should fully understand the characteristics, processes and quality control points of various surface treatment processes, choose suppliers with advanced process technology and strict quality control system, and establish long-term and stable cooperative relations with them. At the same time, paying attention to the development trend of surface treatment processes, such as environmentally friendly processes, multifunctional composite processes, intelligent production lines and personalized customization processes, will help buyers seize opportunities in the market and meet the changing needs of customers. By following scientific and reasonable procurement guidelines, international wholesale buyers can purchase high-quality, high-performance adjustable dumbbell products, thereby standing out in the fierce international market competition and achieving business success.