Dumbbell Factory Inspection Guide

Dumbbell Factory Inspection Guide: A Complete Guide from Demand Matching to Collaboration

For fitness equipment buyers, brands, or cross-border e-commerce sellers, on-site inspections of dumbbell factories are crucial for ensuring product quality and controlling supply chain efficiency. Yongkang City, a hub for China's fitness equipment industry, is home to numerous dumbbell manufacturers. Yongkang Jiebao Industry and Trade Co., Ltd., with its years of production experience and comprehensive supply chain system, has become a key target for many clients. This article, using Jiebao Industry and Trade as an example, will detail the entire dumbbell factory inspection process, helping you efficiently complete your inspection and find your ideal partner.

1. Pre-Inspection Preparation: Clarify Requirements and Target Your Targeting

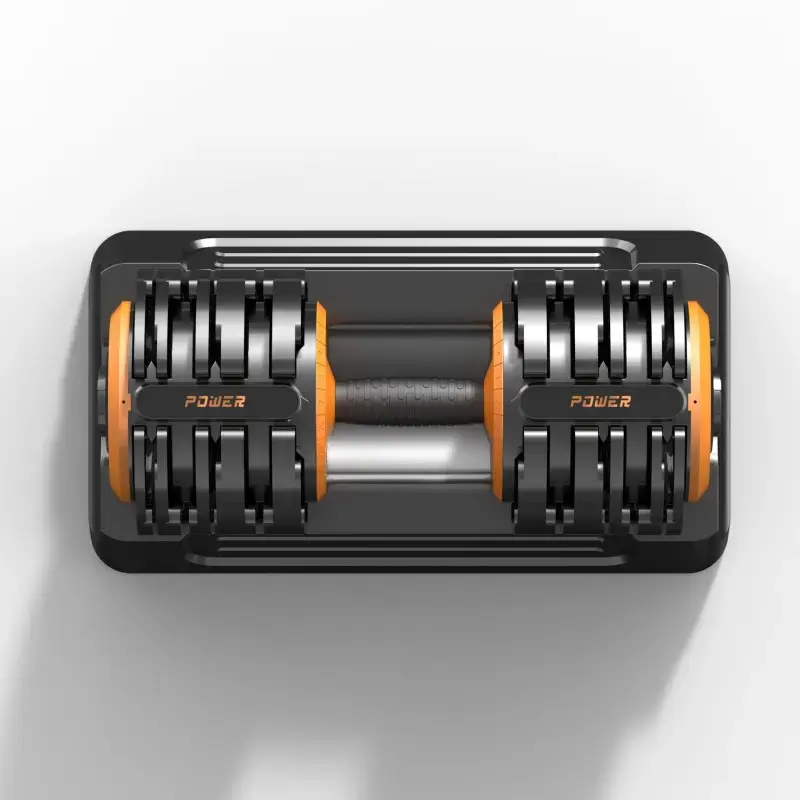

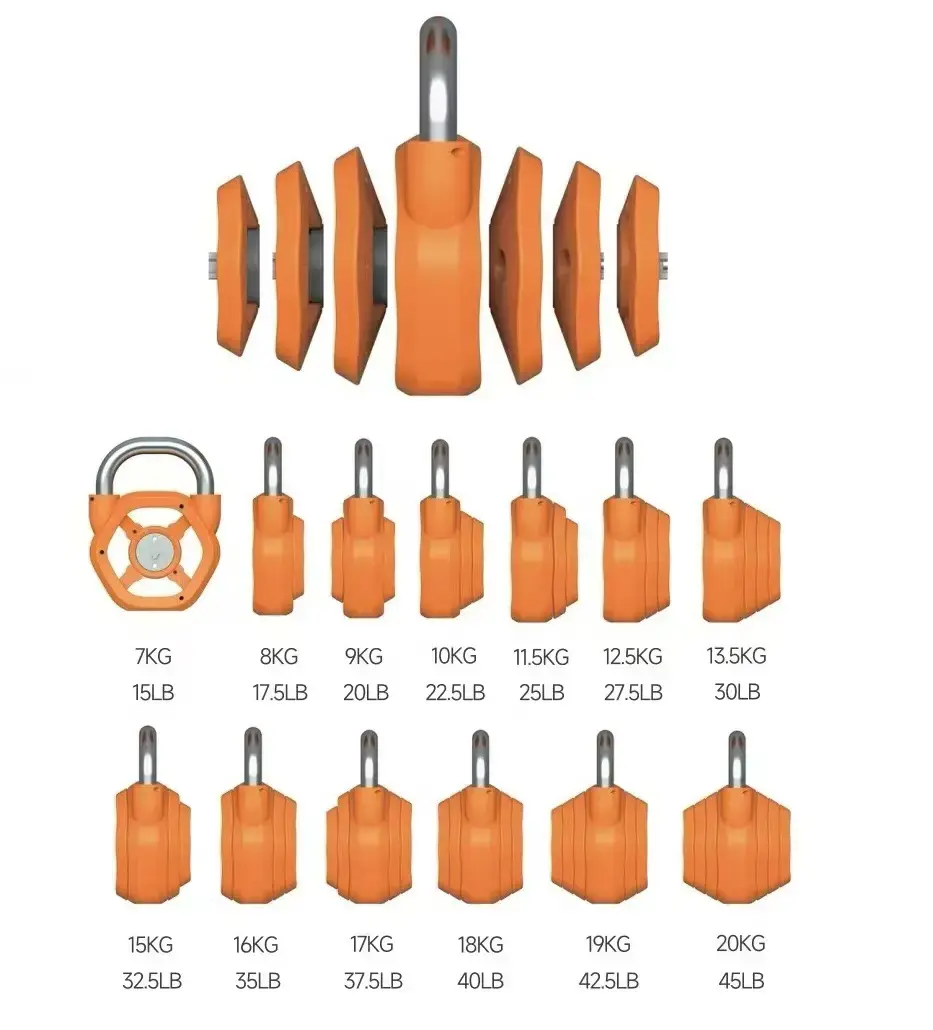

Before heading to a factory, a clear plan of requirements will ensure a more targeted inspection. First, clarify the product type: are you purchasing professional-grade commercial dumbbells (such as Adjustable Dumbbells or fixed-weight dumbbells) or lightweight home dumbbells (such as plastic-coated or rubber-coated dumbbells)? Different types of dumbbells require different production processes and equipment. Jiebao Industry & Trade's production line covers a full range of dumbbell sizes, from 1kg to 50kg, and supports personalized logos, colors, and weight markings. Advance notification of your customization requirements allows the factory to prepare sample plans in advance.

Secondly, determine the purchase scale and lead time. Is it a small trial order (500-1000 pieces) or a large-scale production run (10,000 pieces or more)? Jiebao Industry & Trade has a monthly production capacity of up to 50,000 pieces. However, if specialized processes (such as environmentally friendly plastic dipping or high-precision cast iron) are involved, a 15-20 day production lead time is required. Communicating lead times in advance can avoid time conflicts in subsequent collaborations.

Finally, identify key evaluation criteria. We recommend creating a list based on four key criteria: quality control, production capacity stability, cost advantages, and regulatory compliance. For example, quality concerns include the dumbbell's load-bearing strength and surface finish. Compliance concerns include confirming international certifications such as CE and RoHS (Jiebao Industry and Trade has obtained multiple export certifications; copies of these certificates can be requested in advance).

2. Key Inspection Aspects: In-Depth Visits from Workshop to Laboratory

Upon arrival at the factory, the inspection should cover the entire production chain, with the following four areas being particularly critical:

1. Raw Materials Workshop: The Starting Point of Quality Traceability

The durability of a dumbbell begins with its raw materials. Jiebao Industry and Trade's raw materials warehouse is managed in separate areas, so you should focus on checking the quality inspection reports for the cast iron (e.g., carbon content and hardness). For rubber-coated dumbbells, confirm that the rubber is environmentally friendly (SGS testing reports can be requested) to avoid any odor or excessive levels of harmful substances.

2. Production Workshop: A Visual Reflection of Craftsmanship and Efficiency

When entering the production workshop, you can inspect the production process in order:

Casting: Observe mold precision and the degree of casting automation. Jiebao Industry and Trade uses CNC casting equipment, which can reduce problems with porosity and deformation in castings.

Polishing: Check that the dumbbell surface is smooth and burr-free, which directly affects safety.

Coating/Encapsulation: When inspecting plastic-coated dumbbells, pay attention to the uniformity of the coating thickness and adhesion (you can test this on-site by lightly scratching with a fingernail).

Assembly: For adjustable dumbbells, test the smoothness and locking stability of the adjustment rod to prevent sticking or dislodging during use.

Also, pay attention to the workshop's 5S management (sort, set in order, sweep, clean, and maintain quality). Standardized on-site management often means more reliable quality control.

3. Quality Inspection Laboratory: The "Last Line of Defense" for Quality Control

Professional dumbbell factories are equipped with comprehensive quality inspection equipment. Jiebao Industry and Trade's laboratory can perform a variety of tests:

Load-bearing test: Using a press to simulate 500 extreme load cycles, the dumbbell's structural stability is tested;

Salt spray test: This evaluates the corrosion resistance of metal components to ensure durability in outdoor use or humid environments;

Drop test: This simulates collisions during transportation to verify the impact resistance of the packaging and product.

Request to review recent quality inspection records, focusing on the handling process for defective products to assess the factory's commitment to quality.

4. Warehousing and Logistics: Ensuring Supply Chain Efficiency

When inspecting the finished goods warehouse, pay attention to whether the goods are properly stacked (for example, to avoid deformation caused by heavy pressure) and whether the inbound and outbound records are clear. Jiebao Industry and Trade is located near the Yongkang logistics hub, so you can inquire about logistics solutions tailored to different order volumes. For example, is drop shipping available for small orders? For large-volume exports, do they have a partner customs broker? These details directly impact subsequent delivery efficiency.

3. Post-Inspection Evaluation and Partnership Considerations

After leaving the factory, a comprehensive assessment based on the detailed inspection details is required:

Quality and Price Balance: If the sample testing meets the standards, compare the quotes of similar factories. Jiebao Industry and Trade's bulk purchase price typically includes the costs of raw materials, processing, and quality inspection. Excessively low prices may conceal quality risks.

Flexibility of Cooperation: Confirm whether small-batch trial production is supported and whether OEM/ODM customization is accepted (e.g., designing dumbbell shapes according to brand requirements).

After-Sales Guarantee: Inquire about the after-sales policy for quality issues, such as whether defective products can be returned or exchanged, and how long the return and exchange period is.

Long-Term Cooperation Potential: Understand the factory's R&D capabilities. Jiebao Industry and Trade updates 2-3 new dumbbell designs annually based on market demand (e.g., lightweight materials, smart counting functions). Choosing an innovative factory can enhance product competitiveness.

If a preliminary cooperation intention is reached, it is recommended to sign a detailed purchase contract that clearly defines terms such as quality standards, delivery time, and liability for breach of contract. Jiebao Industry and Trade can provide standardized contract templates and can adjust details based on customer needs.

Conclusion

A visit to a dumbbell factory is not only a test of the product, but also a verification of the reliability of the supply chain. Yongkang Jiebao Industry and Trade Co., Ltd., adhering to the principle of "quality first, win-win cooperation," welcomes customers from all walks of life to visit our factory. Our transparent management of the entire process, from raw materials to finished product, will provide a solid basis for your purchasing decisions. To schedule a visit or obtain samples, please contact our account manager through our official website. We look forward to working with you to build a high-quality fitness equipment supply chain.