How to ensure the accuracy of adjustment of three-in-one adjustable dumbbells?

How to ensure the accuracy of adjustment of three-in-one Adjustable Dumbbells?

In the field of fitness equipment, three-in-one adjustable dumbbells are favored by many fitness enthusiasts for their convenience and versatility. For international wholesale buyers, product quality and performance are their focus, and adjustment accuracy, as one of the key indicators to measure the quality of three-in-one adjustable dumbbells, is directly related to the user experience and training effect. This article will explore in depth how to ensure the accuracy of adjustment of three-in-one adjustable dumbbells to help companies win the trust and recognition of buyers in the international market.

1. Carefully designed mechanical structure

(I) Accurate weight plate design

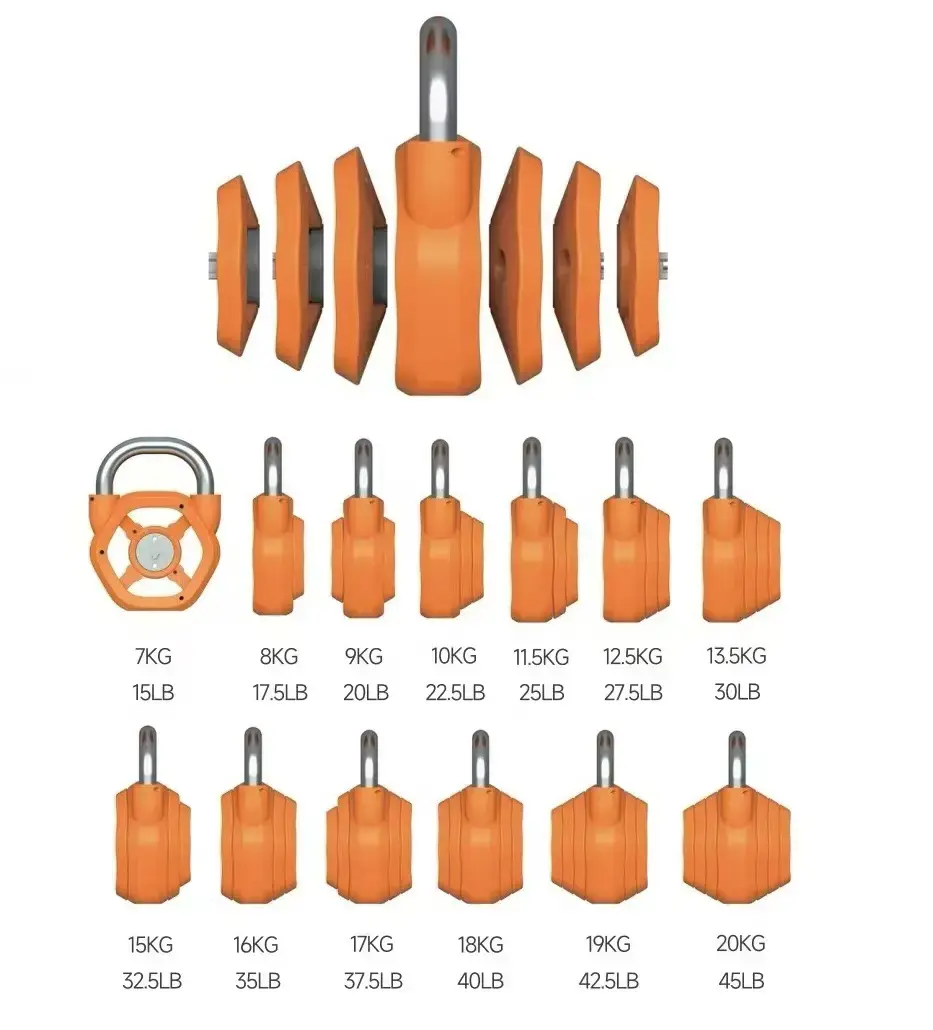

The weight plate is the core component of the adjustable dumbbell, and the accuracy of its quality is the basis for achieving adjustment accuracy. In the production process, high-precision mold manufacturing technology is required to ensure that the weight error of each weight plate is controlled within a very small range. For example, through advanced CNC processing equipment, the mold is precisely processed to make the size and shape of the weight plate highly consistent, thereby ensuring the accuracy of the weight. At the same time, the shape and installation method of the weight plate should be reasonably designed to ensure that it can be stably fixed in the corresponding position during the adjustment process, avoiding inaccurate weight adjustment due to loosening or offset of the weight plate.

(II) Precision adjustment mechanism

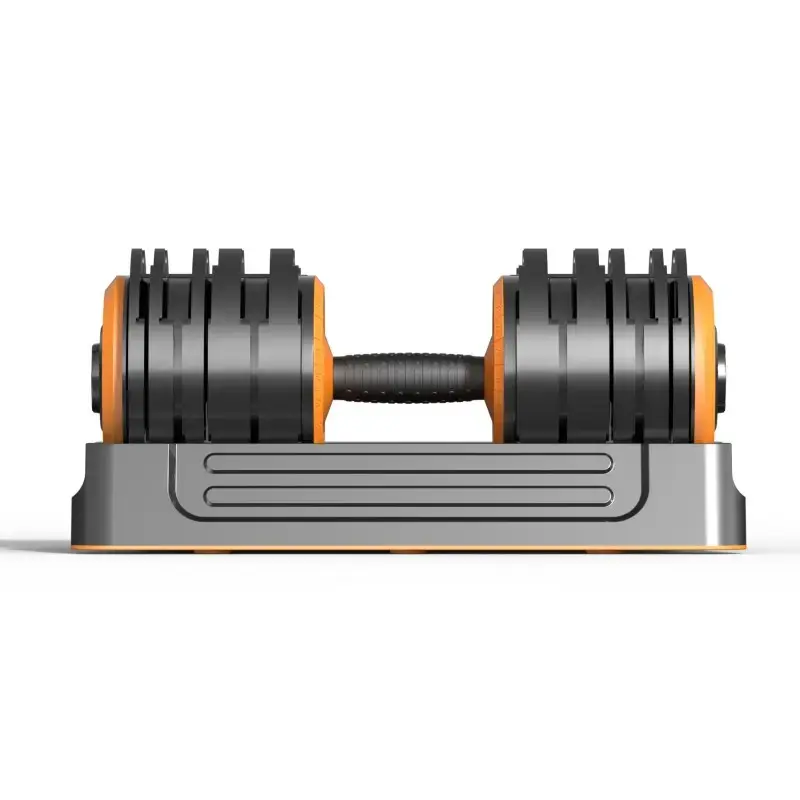

Designing a set of precise and reliable adjustment mechanisms is crucial to ensure the accuracy of adjustment. Common adjustment mechanisms include knob type, button type and lever type. Taking the knob type adjustment mechanism as an example, it usually has a precise gear transmission system inside, which realizes the precise switching of the weight plate by accurately controlling the meshing and rotation of the gears. When designing, the gear module, number of teeth, tooth shape and other parameters should be fully considered to ensure the accuracy and stability of the gear transmission. In addition, the locking device of the adjustment mechanism must also be reasonably designed to be able to firmly lock the weight plate after adjustment, prevent the weight from changing due to vibration or other external forces during use, and ensure that users can use stable weight for training when exercising.

2. Adopting high-precision manufacturing technology

(I) Advanced casting and processing technology

In the production and manufacturing process of three-in-one adjustable dumbbells, advanced casting and processing technology is the key link to ensure the accuracy of adjustment. For the main parts of dumbbells, such as handles and weight plate holders, high-precision casting processes are used to ensure that their dimensional accuracy and shape accuracy meet the design requirements. For example, by using computer numerical control (CNC) casting technology, by accurately controlling casting parameters such as temperature, pressure, speed, etc., the cast parts have good surface quality and dimensional consistency.

In the subsequent mechanical processing process, high-precision CNC processing equipment is used to finely process the parts to further improve their dimensional accuracy and matching accuracy. For example, for key parts such as the inner hole of the handle and the mounting hole of the weight plate holder, high-precision boring, reaming and other processing procedures are performed to ensure that the matching clearance with the weight plate and other components is uniform and reasonable, thereby ensuring the flexibility and stability of the adjustment mechanism.

(II) Strict assembly process control

The assembly process has a direct impact on the adjustment accuracy of the three-in-one adjustable dumbbell. During the assembly process, operations must be strictly carried out in accordance with the process specifications to ensure the correct installation and close fit of each component. First of all, professional training should be provided to the assemblers to make them familiar with the structure and assembly process of the product and master the correct assembly methods and techniques. Secondly, use advanced assembly equipment and tools, such as high-precision torque wrenches and presses, to ensure that the assembly force of parts is uniform and consistent, and avoid problems such as inflexible adjustment or weight deviation caused by loose or tight assembly.

At the same time, strict inspection procedures should be set up during the assembly process to conduct comprehensive inspections on the assembled dumbbells, including the accuracy of weight adjustment, the operational flexibility of the adjustment mechanism, the reliability of the locking device, etc. For products that fail the inspection, they should be reworked in time to ensure that every three-in-one adjustable dumbbell shipped from the factory meets high quality standards and has precise adjustment performance.

3. Accurate electronic control system (for smart models)

With the continuous development of technology, more and more three-in-one adjustable dumbbells are equipped with electronic control systems to achieve more convenient and accurate weight adjustment functions. For this type of Smart Dumbbells, the accuracy of their electronic control systems directly determines the accuracy of adjustment.

(I) High-precision sensors and chips

In the electronic control system, the sensor is responsible for real-time monitoring of the weight instructions input by the user and the current weight status of the dumbbell, and transmits this information to the control chip for processing. Therefore, the use of high-precision and high-sensitivity sensors is the basis for ensuring the accuracy of the electronic control system. For example, the weight sensor can accurately sense the weight change of the weight plate and convert it into an electrical signal to transmit to the control chip; the angle sensor can accurately detect the rotation angle of the handle so that the control chip can determine the corresponding weight adjustment position according to the preset program.

As the core component of the electronic control system, the control chip needs to have strong data processing capabilities and high-precision computing performance. It can quickly and accurately analyze the data transmitted by the sensor, and issue corresponding instructions according to the built-in control algorithm to drive the motor and other actuators to complete the weight adjustment action. The selection of high-performance and high-quality chips can effectively improve the response speed and adjustment accuracy of the electronic control system, ensuring that the weight set by the user can be accurately achieved.

(II) Accurate motor drive and control technology

As the power source for driving the weight plate to move, the accuracy of its drive and control technology is crucial to the adjustment accuracy. The accurate motor drive system can accurately control the motor speed and rotation angle according to the instructions issued by the control chip, thereby achieving accurate positioning of the weight plate. The use of advanced motor drive chips and control algorithms can effectively improve the control accuracy and operation stability of the motor.

For example, by adopting closed-loop control technology, the feedback signal of the motor is monitored in real time, compared with the target position, and automatically adjusted according to the error, ensuring that the motor can accurately drive the counterweight to the specified position and achieve accurate weight adjustment. At the same time, optimizing the transmission mechanism of the motor, such as using high-precision gear reducers, screw nut pairs, etc., can further improve the accuracy and stability of the transmission, reduce the weight deviation caused by transmission errors, and improve the adjustment accuracy of the three-in-one adjustable dumbbells.

4. Strict quality inspection and calibration

(I) Multi-link quality inspection

In order to ensure the accuracy of the adjustment of the three-in-one adjustable dumbbells, it is necessary to set up multi-link quality inspection processes in the production process to conduct comprehensive and detailed inspections of the products. First of all, in the raw material procurement link, the quality of the raw materials must be strictly inspected to ensure that its composition, performance and other indicators meet the relevant standards and product design requirements, and to ensure product quality from the source.

In the process of parts processing, each key component is inspected for dimensional accuracy, shape accuracy, surface quality, etc., and unqualified components are discovered and processed in a timely manner to prevent them from flowing into the next process. After the whole machine is assembled, a comprehensive function test and performance test are carried out, including weight adjustment accuracy test, adjustment mechanism flexibility test, locking device reliability test, durability test, etc., to simulate various situations in actual use by users, and repeatedly test and verify the product to ensure that its adjustment accuracy can meet the needs of users and the requirements of relevant standards.

(II) Regular calibration and maintenance

In addition to strict quality inspection during the production process, for the three-in-one adjustable dumbbells that have been sold, users need to be reminded to perform regular calibration and maintenance to maintain their adjustment accuracy. In the product manual, the calibration method and steps, as well as the recommended calibration cycle, should be explained in detail to help users perform calibration operations correctly. For example, for mechanically adjusted dumbbells, users can regularly check whether the locking device of the adjustment mechanism is loose, whether the weight plate is worn, etc. according to the instructions in the manual, and make corresponding adjustments and replacements; for electronically controlled dumbbells, users can use calibration tools to calibrate the electronic control system according to the requirements of the manual to ensure the normal operation and accurate measurement of sensors, chips and other components.

At the same time, enterprises can provide users with more comprehensive after-sales service support, including professional maintenance and technical consulting services, timely solve problems encountered by users during use, ensure the long-term stable operation and precise adjustment performance of the product, thereby improving user satisfaction and the market reputation of the product.

5. Optimize product design and user experience

(I) Humanized design concept

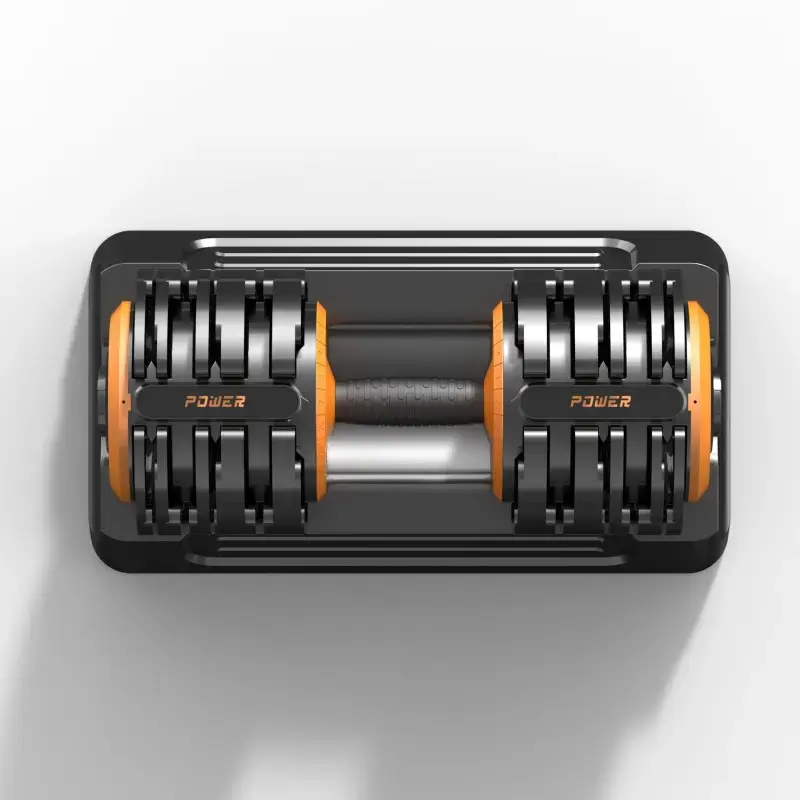

In the product design stage of three-in-one adjustable dumbbells, fully integrate the humanized design concept, optimize the product structure and adjustment method based on the actual usage scenarios and operating habits of users, which will help improve the accuracy of adjustment and user experience. For example, design a simple and clear operation interface so that users can intuitively understand the current weight and adjustment range of the dumbbells and set the weight conveniently. For mechanically adjusted dumbbells, the design of the handle should conform to the principles of ergonomics to ensure that users can easily hold the handle when adjusting the weight and apply appropriate force to operate, while avoiding problems such as inaccurate adjustment or inconvenient operation caused by unreasonable handle design.

In addition, the weight classification of the weight plate is reasonably set, and the weight classification is designed to be more refined and reasonable according to common fitness training needs and user habits, so that users can more accurately choose the training weight that suits them, improve training effects and satisfaction.

(II) Enhance product stability and reliability

Improving the stability and reliability of the three-in-one adjustable dumbbell can effectively reduce the problem of inaccurate adjustment caused by product failure or unstable factors. In the product structure design, pay attention to the overall balance and center of gravity distribution to ensure that the dumbbell can remain stable in various placement states and during use, and will not affect the accuracy of the fixation and weight adjustment of the weight plate due to shaking or tilting. Use high-quality materials and sturdy and durable connection methods to enhance the connection strength between the various components of the product and the stability of the overall structure, so that the product can withstand long-term use and certain external force impact, and reduce the adjustment error caused by loose components, damage and other problems.

At the same time, reliability design and life testing are carried out on the key components and wearing parts of the product, and their structure and materials are optimized to improve their wear resistance, fatigue resistance and other properties to ensure the stable operation and precise adjustment of the product during its service life, and provide users with a cost-effective and reliable fitness equipment.

In summary, ensuring the accuracy of the three-in-one adjustable dumbbell adjustment requires multiple aspects, including carefully designed mechanical structure, high-precision manufacturing process, precise electronic control system (for smart models), strict quality inspection and calibration, and optimization of product design and user experience. Only by constantly pursuing excellence in these aspects and strictly controlling every link can enterprises produce high-quality and high-precision three-in-one adjustable dumbbell products, meet the strict requirements of international wholesale buyers for product quality and performance, stand out in the fierce international market competition, win the trust of users and market recognition, promote the development and innovation of the fitness equipment industry, and provide more high-quality and efficient fitness solutions for global fitness enthusiasts, helping people realize the vision of a healthy and beautiful life.