How to ensure the durability of the coating of dumbbells

How to ensure the durability of the coating of dumbbells

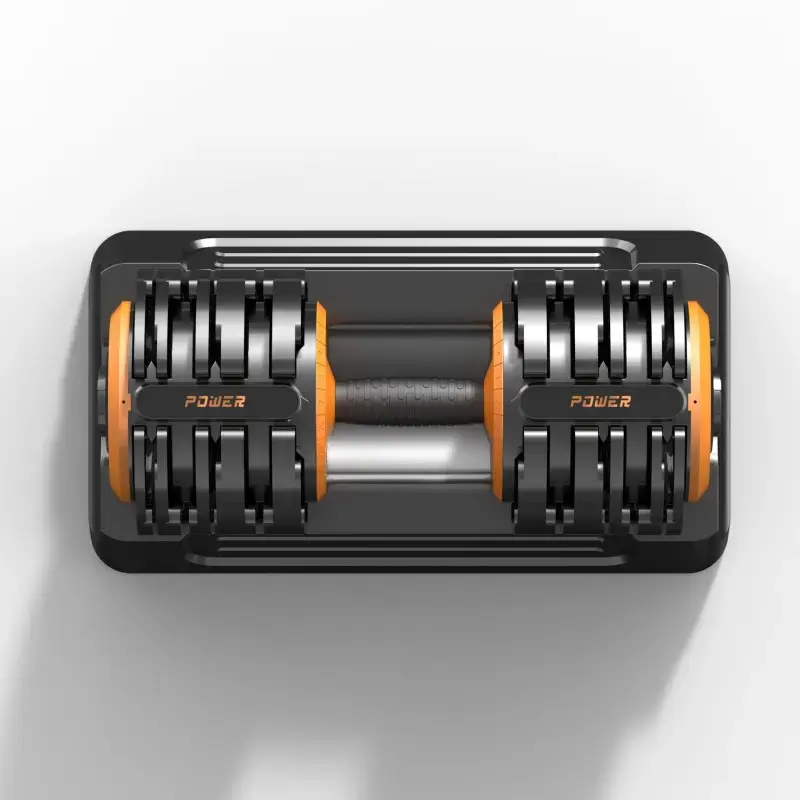

In the field of fitness equipment, dumbbells are one of the basic and commonly used equipment. Their quality and durability are directly related to the user experience and the service life of the product. The coating of dumbbells not only affects their appearance, but also largely determines the durability of dumbbells. This article will explore in depth how to ensure the durability of dumbbell coatings, including material selection, process optimization, quality control, and test evaluation.

I. Selection of coating materials

(I) Polyurethane material

Polyurethane is a high-performance polymer material with high strength, high elasticity, wear resistance, and oil resistance. High-quality polyurethane coating can provide excellent protection for dumbbells. For example, Livepro's LP8000 polyurethane dumbbells use the highest grade polyurethane material on the market. Its matte particle surface not only looks textured, but also has the characteristics of wear resistance and fall resistance. It is not easy to fade, crack, peel or degrade, has high stability, and has no odor.

(II) Rubber material

Rubber coating is also one of the common choices for dumbbells. Rubber has good elasticity, wear resistance and shock absorption, which can effectively reduce the damage of dumbbells to the ground during use, and also increase the anti-rust performance. Some high-quality Rubber-Coated Dumbbells have rubber materials that have been specially treated to improve adhesion with the dumbbell body and enhance durability.

(III) Special composite materials

In order to further improve the durability of dumbbell coatings, some manufacturers have begun to use special composite materials. For example, there is a kind of anti-fall and friction-resistant dumbbell, whose anti-fall and friction-resistant layer is a mixture of an anti-fall layer and a friction-resistant layer in a certain proportion. The anti-fall layer contains chloroprene rubber, lupine palmitate, amino resin and other ingredients, and the friction-resistant layer contains bisphenol f type liquid epoxy resin, sodium lignin sulfonate and other ingredients. This composite coating makes the dumbbells excellent in anti-fall and friction resistance, greatly improving the durability of the product.

II. Optimizing the coating process

(I) Surface pretreatment

Before coating, it is crucial to pretreat the surface of the dumbbell body. This step can improve the adhesion between the coating and the body, thereby enhancing the durability of the coating. Common surface pretreatment methods include:

Degreasing: Use alkaline solution or organic solvent to remove oil, dust and other impurities on the surface of the dumbbell to ensure the surface is clean.

Sandblasting: Sandblasting is used to form a certain degree of roughness on the surface of the dumbbell, increase the adhesion area of the coating, and improve the adhesion.

Chemical treatment: Use chemical converters to generate a dense chemical conversion film on the surface of the dumbbell to enhance the bonding between the coating and the body.

(II) Coating construction process

Spraying process: Spraying is one of the common coating construction methods. The key is to control the spraying parameters, such as the distance, angle, pressure and speed of the spray gun. Ensure that the coating is evenly covered on the surface of the dumbbell to avoid defects such as sagging and missing coating. At the same time, according to the characteristics and requirements of the coating material, select appropriate spraying equipment and process parameters.

Dip coating process: Immerse the dumbbell completely in the coating material, then slowly lift it up to allow the excess coating material to flow naturally. This method can ensure uniform thickness of the coating and improve the quality and performance of the coating. However, during the dipping process, it is necessary to pay attention to controlling the temperature, viscosity and pulling speed of the coating material to ensure the effect of the coating.

Electrophoretic coating process: For dumbbells made of metal, electrophoretic coating is an effective coating process. Through the action of the electric field, the charged coating particles are adsorbed to the surface of the dumbbell to form a uniform and dense coating. Electrophoretic coating has the advantages of uniform coating, strong adhesion and high coating efficiency, which can significantly improve the durability of the dumbbell coating.

(III) Curing process

The curing of the coating is a key link to ensure its performance. Different coating materials require different curing processes. Common curing methods include natural drying, thermal curing, and ultraviolet light curing.

Natural drying: For some water-based coatings or low-solid coatings, they can be dried naturally at room temperature. However, the speed of natural drying is relatively slow, and the performance of the coating may be greatly affected by environmental factors.

Thermal curing: Thermal curing is one of the most widely used curing methods. Put the coated dumbbells into an oven and heat them under certain temperature and time conditions to make the coating undergo a cross-linking reaction to form a hard and durable coating. The temperature and time of thermal curing need to be precisely controlled according to the characteristics of the coating material to ensure that the performance of the coating reaches the best state.

UV curing: UV curing technology has the advantages of fast curing speed, energy saving, and excellent coating performance. Through the irradiation of ultraviolet light, the photoinitiator in the coating material initiates a polymerization reaction and quickly forms a coating. This method is particularly suitable for some coating materials that have high requirements for curing speed.

III. Quality control and testing

(I) Raw material quality control

Ensuring the quality of coating materials is the basis for producing durable dumbbells. Manufacturers need to strictly screen and evaluate raw material suppliers to establish long-term and stable cooperative relationships. Strict quality inspection is carried out on each batch of coating raw materials, including material composition analysis, performance testing, etc., to ensure that the raw materials meet relevant standards and quality requirements.

(II) Quality monitoring during the production process

During the production process of dumbbells, a complete quality monitoring system should be established to monitor all aspects of coating construction in real time. For example, the thickness, uniformity and other parameters of the coating can be detected through online monitoring equipment to promptly discover and correct quality problems in the production process. At the same time, the production environment must be strictly controlled, including temperature, humidity, cleanliness, etc., to ensure that the production conditions meet the requirements of coating construction.

(III) Finished product inspection

The finished dumbbells coated with the coating are comprehensively inspected, including appearance quality inspection and performance inspection. Appearance quality inspection mainly checks whether the surface of the coating has defects such as scratches, bubbles, orange peel, etc., whether the color is uniform, etc. Performance inspection includes adhesion test, wear resistance test, corrosion resistance test, impact resistance test, etc.

IV. Test methods for evaluating coating durability

(I) Adhesion test

Adhesion is an important indicator to measure the degree of firmness of the coating and the dumbbell body. Commonly used adhesion test methods include the grid method and the pull-off method. The grid method is to draw a grid of a certain size on the surface of the coating, then stick it with tape and tear it off, and observe the shedding of the coating on the edge of the grid to evaluate the adhesion. The pull-off method is to use a special pull-off device to pull the coating off the body, measure the required pull-off force, and thus evaluate the strength of the adhesion.

(ii) Wear resistance test

The wear resistance test is used to evaluate the ability of the coating to resist wear during use. Common wear resistance test methods include Taber wear test and Martindale wear test. Taber wear test is to install the dumbbell sample on a rotating turntable, apply a certain load, let the abrasive contact and rub the coating surface, and measure the wear of the coating after a certain number of revolutions. Martindale wear test is to test the wear resistance of the coating by simulating the friction of the fabric in actual use.

(iii) Corrosion resistance test

The corrosion resistance test is mainly used to detect the resistance of the coating to the corrosive media in the surrounding environment. Salt spray test is one of the commonly used corrosion resistance test methods. Put the coated dumbbell sample into the salt spray test chamber, spray a certain concentration of salt solution under certain temperature and humidity conditions, and observe the corrosion of the coating surface after a certain period of time, such as blistering, rusting, peeling, etc., to evaluate the corrosion resistance of the coating.

(iv) Impact resistance test

The impact resistance test is used to evaluate the resistance of the coating when it is impacted by external forces. By dropping a certain weight of a hammer from a certain height to hit the surface of the dumbbell sample coated with the coating, the cracking and shedding of the coating are observed to determine the impact resistance of the coating.

(V) Accelerated light aging test

The accelerated light aging test can simulate the aging of the coating after long-term exposure to the outdoor environment. The xenon arc lamp test is one of the commonly used accelerated light aging test methods. The dumbbell sample is placed in a xenon arc lamp test chamber, and the effects of natural environments such as sunlight, rain, and dew on the coating are simulated by controlling the light intensity, temperature, humidity and other conditions. After a period of time, the aging phenomena such as discoloration, cracking, and powdering of the coating are observed to predict the life of the coating in actual use.

V. Daily maintenance and care

(I) Cleaning method

In daily use, keeping the dumbbell clean is one of the important measures to extend the life of the coating. For dust and stains on the surface, you can use a soft dry cloth to gently wipe it. If you encounter stubborn stains, you can use an appropriate amount of mild detergent and a damp cloth to clean it, but be careful to avoid using too damp cloth to prevent moisture from penetrating into the coating, causing the coating to fall off or rust. After cleaning, the surface of the dumbbell should be wiped dry with a dry cloth immediately.

(ii) Storage environment

The storage environment of the dumbbell also has a great impact on the durability of its coating. The dumbbells should be stored in a dry, ventilated, and cool place, and avoid long-term exposure to sunlight or humid environments. At the same time, avoid contact with other chemicals to avoid corrosion or damage to the coating. In places such as gyms, special storage racks can be equipped for dumbbells to store them in an orderly manner to reduce collisions and friction.

(iii) Regular inspection

Check the dumbbells regularly to detect damage to the coating in time. If the coating is found to have slight scratches or wear, a touch-up pen with a color similar to the coating can be used to repair it to prevent the scratches from further expanding. For areas where the coating has fallen off or rusted, the coating should be cleaned and re-coated in time to ensure the normal use and service life of the dumbbells.

In summary, ensuring the durability of dumbbell coatings requires multiple aspects. By selecting high-quality coating materials, optimizing coating processes, strict quality control and testing, and correct daily maintenance and care, the durability of dumbbell coatings can be greatly improved, the service life of the product can be extended, and a satisfactory user experience can be provided to users. For international wholesale buyers, paying attention to the durability of dumbbell coatings and choosing products with good coating quality can not only improve the market competitiveness of products, but also reduce after-sales problems and enhance customer satisfaction and loyalty.