How to improve the durability of the adjustable dumbbell adjustment mechanism

How to improve the durability of the Adjustable Dumbbell adjustment mechanism

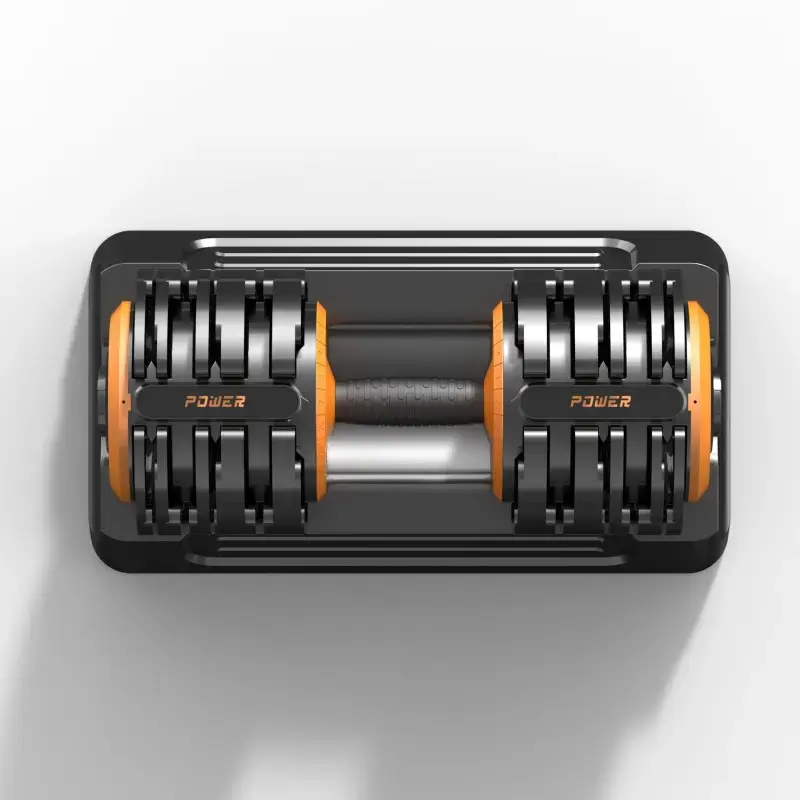

In the field of fitness equipment, adjustable dumbbells are favored by many fitness enthusiasts for their convenience and practicality. As one of the core components of Adjustable Dumbbells, the durability of the adjustment mechanism is directly related to the service life and user experience of the product. For the independent adjustable dumbbell station facing international wholesale buyers, providing high-quality and durable adjustment mechanism products is the key to improving market competitiveness and establishing a good brand image. The following will discuss in detail how to improve the durability of the adjustable dumbbell adjustment mechanism from multiple aspects.

1. Optimize material selection

When designing the adjustable dumbbell adjustment mechanism, high-strength, wear-resistant and corrosion-resistant materials should be used first to ensure its stability and reliability during long-term use.

High-strength alloy steel: This material has excellent mechanical properties, such as high strength, high hardness and good toughness, and can withstand large tensile and compressive stresses. Using high-strength alloy steel in the active parts of the adjustment mechanism, such as threaded rods, adjustment knobs, etc., can effectively prevent deformation and wear caused by long-term use and extend the service life of the adjustment mechanism.

Stainless steel material: Stainless steel has good corrosion resistance and can maintain good performance in a humid environment. At the same time, stainless steel also has high strength and hardness, which can meet the use requirements of the adjustment mechanism. The use of stainless steel to manufacture the outer shell, fixed bracket and other parts of the adjustment mechanism can not only improve the aesthetics of the adjustment mechanism, but also effectively prevent rust and corrosion, and reduce the impact of environmental factors on the adjustment mechanism.

Engineering plastics: Some high-performance engineering plastics, such as nylon, polyoxymethylene, etc., have good wear resistance, self-lubrication and fatigue resistance. Using engineering plastics in non-metallic parts of the adjustment mechanism, such as gears and gaskets, can reduce the friction coefficient between parts and reduce wear. At the same time, it can also reduce the weight of the adjustment mechanism and improve its operational flexibility.

2. Improve the design structure

Reasonable adjustment mechanism design is one of the key factors to improve its durability. Through optimized design, the force performance, stability and reliability of the adjustment mechanism can be improved, thereby extending its service life.

Optimize thread design: In the adjustment mechanism of adjustable dumbbells, threaded connection is one of the common connection methods. In order to improve the strength and reliability of threaded connections, measures such as multi-threading, increasing the thread diameter and pitch, etc. can be adopted. At the same time, the shape of the thread should also be optimized, such as using trapezoidal threads or serrated threads, to increase the load-bearing capacity and self-locking performance of the thread, and prevent adjustment failure caused by thread sliding.

Add support structure: Add corresponding support structures, such as bearings and supports, to the key parts of the adjustment mechanism, such as the support points of the threaded rod and the connection of the adjustment knob, which can effectively disperse stress and reduce wear and deformation between components. In addition, the reasonable arrangement of the position and shape of the support structure can also improve the stability of the adjustment mechanism and the smoothness of operation, and reduce the risk of damage to the adjustment mechanism caused by improper operation or external force impact.

Set a limit device: Setting a limit device within the range of motion of the adjustment mechanism can effectively prevent damage caused by excessive movement of the adjustment component. For example, limit blocks are set at both ends of the threaded rod to limit the rotation angle of the adjustment knob. The design of the limit device should be reasonable and reliable, and can play a limiting role in time when the adjustment mechanism reaches the limit position, while not affecting the normal use and operation convenience of the adjustment mechanism.

3. Improve the manufacturing process

Advanced manufacturing technology can ensure that the parts of the adjustment mechanism have high precision and good surface quality, thereby improving the assembly accuracy and overall performance of the adjustment mechanism and enhancing its durability.

Precision machining technology: Using precision machining technology, such as CNC lathes, machining centers and other equipment, to process and manufacture the parts of the adjustment mechanism can ensure the dimensional accuracy and shape accuracy of the parts, improve the machining quality of key parts such as threads and gears, and reduce the interference and wear between parts caused by manufacturing errors. At the same time, precision machining can also obtain good surface finish, reduce the friction coefficient between parts, and increase the service life of the adjustment mechanism.

Heat treatment process: Reasonable heat treatment processes such as quenching, tempering, and surface hardening can be performed on the metal parts of the adjustment mechanism to improve the hardness, strength and wear resistance of the parts. For example, quenching treatment of key parts such as threaded rods and adjustment knobs can form a high-hardness hardened layer on their surface to enhance their wear resistance; while tempering treatment can eliminate the internal stress generated during the quenching process, improve the toughness and fatigue resistance of parts, and extend their service life.

Surface treatment technology: Using surface treatment technology, such as electroplating, painting, chemical plating, etc., to treat the parts of the adjustment mechanism can not only improve the corrosion resistance of the parts, but also improve the friction performance and aesthetics of the surface. For example, spray painting the stainless steel adjustment mechanism can not only prevent surface scratches and corrosion, but also increase the color and texture of the product and improve the added value of the product. In addition, some special surface treatment technologies, such as physical vapor deposition (PVD) and chemical vapor deposition (CVD), can also form a layer of coating with high hardness and low friction coefficient on the surface of the parts, further improving the wear resistance and service life of the adjustment mechanism.

4. Strengthen quality control

A strict quality control system is the basis for ensuring the durability of the adjustable dumbbell adjustment mechanism. From raw material procurement to production and processing, to finished product inspection, every link should be strictly inspected and controlled to ensure that the product quality meets the standard requirements.

Raw material inspection: Strict quality inspection of the purchased raw materials, including the chemical composition, mechanical properties, appearance quality and other aspects of the materials. Ensure that the quality of the raw materials meets the design requirements and relevant standards to avoid the performance degradation and shortened service life of the adjustment mechanism caused by raw material quality problems.

Production process monitoring: During the production and processing process, each process is monitored and controlled in real time. For example, the operating status of the processing equipment is monitored to ensure the accuracy and stability of the equipment; the processing parameters are strictly controlled, such as cutting speed, feed rate, processing temperature, etc., to ensure the processing quality of parts; employees are trained in skills and quality awareness, to improve their operating level and quality awareness, and to reduce quality problems caused by human factors.

5. Optimize the use and maintenance instructions

Provide detailed and clear use and maintenance instructions for adjustable dumbbells for international wholesale buyers, which helps users to use and maintain the products correctly, thereby extending the service life of the adjustment mechanism.

Detailed operation guide: Provide the operating steps and methods of the adjustment mechanism in the manual, including detailed operating instructions on how to properly install, adjust the weight, and disassemble. At the same time, precautions during operation should be emphasized, such as avoiding excessive force, preventing foreign matter from entering the adjustment mechanism, etc., to prevent damage to the adjustment mechanism due to incorrect operation.

Regular maintenance suggestions: Provide suggestions and methods for regular maintenance, such as regular cleaning, lubrication, and inspection of the adjustment mechanism. Cleaning can remove dust, dirt and sweat on the surface of the adjustment mechanism to prevent corrosion and wear on the adjustment mechanism; lubrication can reduce the friction coefficient between components, reduce wear, and improve the flexibility and service life of the adjustment mechanism; inspection can timely discover potential problems in the adjustment mechanism, such as loose threads, worn components, etc., and repair and replace them in time to avoid further expansion of the problem.

Troubleshooting and maintenance: Common fault phenomena, cause analysis and troubleshooting methods are provided in the manual to help users make timely and accurate judgments and solve problems when they encounter problems. For some more complex faults or situations that require professional maintenance, clear maintenance contact information and after-sales service channels should be provided to ensure that users can get timely and effective technical support and maintenance services, and improve user satisfaction and loyalty to the product.

In summary, improving the durability of the adjustable dumbbell adjustment mechanism requires starting from material selection, design structure, manufacturing process, quality control, and instructions for use and maintenance. By comprehensively using various technologies and management methods, we continuously improve the performance and quality of the adjustment mechanism, which can meet the high requirements of international wholesale buyers on product quality and service life, lay a solid foundation for the market promotion and brand building of adjustable dumbbells, stand out in the fierce market competition, and win a broader market share and a good reputation.