Key strategies to ensure the durability of adjustable dumbbells

Key strategies to ensure the durability of Adjustable Dumbbells

Introduction

With the global popularity of fitness culture, adjustable dumbbells are favored by many fitness enthusiasts for their convenience and versatility. For international wholesale buyers, product durability is one of the key factors in determining whether to cooperate long-term. This article will explore in depth how to ensure the durability of adjustable dumbbells from aspects such as material selection, structural design, manufacturing process, quality control and after-sales service, so as to help your independent stand out in the international market.

I. Careful material selection

1. Main material

High-quality steel: The main part of the adjustable dumbbell, such as the connecting shaft of the handle and the weight plate, is often made of high-strength alloy steel. It has high tensile strength and yield strength, and can withstand long-term heavy pressure and repeated use without deformation or breakage. For example, the handle of a well-known brand of adjustable dumbbells is made of alloy steel that has undergone special heat treatment, with high surface hardness and good wear resistance. It can maintain good performance even in a high-intensity training environment.

New environmentally friendly alloy: The weight plates of some high-end adjustable dumbbells will use new environmentally friendly alloy materials. This material not only has high density and can provide more weight in a limited space, but also has good corrosion resistance and aging resistance, and is not easily affected by sweat, humid environment and other factors, thus extending the service life of dumbbells.

2. Rubber coating material

High elastic rubber coating: A layer of high elastic rubber coating is usually wrapped on the outer layer of the weight plate. This rubber coating material is soft and has good elasticity. It can play a role in shock absorption and buffering during the use of dumbbells, reducing the impact force on the ground, and also reducing the noise caused by collision. Moreover, the high elastic rubber coating has a certain wear resistance, is not easy to be scratched or worn, and can effectively prevent sweat and moisture from penetrating into the internal weight plate and connecting parts, playing a certain protective role.

Anti-aging TPR: TPR (thermoplastic rubber) is a common rubber coating material with excellent anti-aging properties. It can maintain the performance of the material stable under long-term light, oxidation and other environments, and is not prone to cracking, hardening and other phenomena, thereby ensuring that the appearance and performance of the dumbbells are not affected and improving the durability of the product.

2. Scientific structural design

1. Stable connection structure

Precise threaded connection: The connection between the handle and the weight plate of the adjustable dumbbell is usually threaded. High-quality thread processing has high precision, the thread profile is complete, smooth, and tightly matched. When adjusting the weight, by rotating the adjustment knob or nut, the weight plate can be firmly fixed to the handle to prevent loosening or slipping during use, ensuring the safety and stability of training. At the same time, the tight threaded connection can also effectively avoid wear of the connection parts caused by long-term use and extend the service life of the product.

Built-in stop device: Some advanced adjustable dumbbells are designed with built-in stop devices, such as spring buckles or stop pins. These devices can further provide additional locking force after the weight plate is fixed to prevent the weight plate from accidentally loosening due to vibration or external force caused by intense exercise, enhance the reliability of the connection, and improve the durability of the product.

2. Reasonable weight system

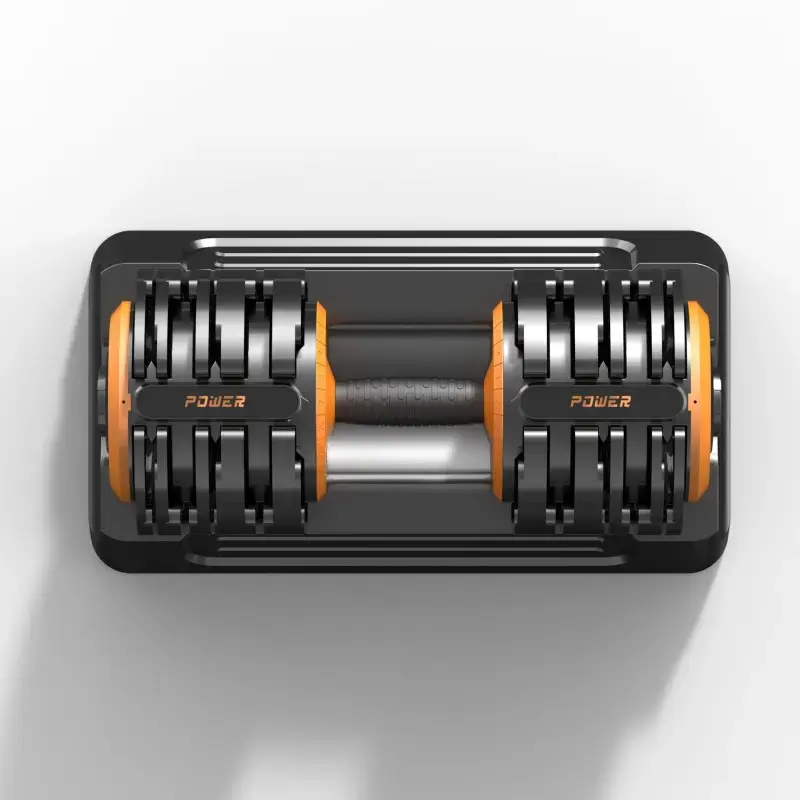

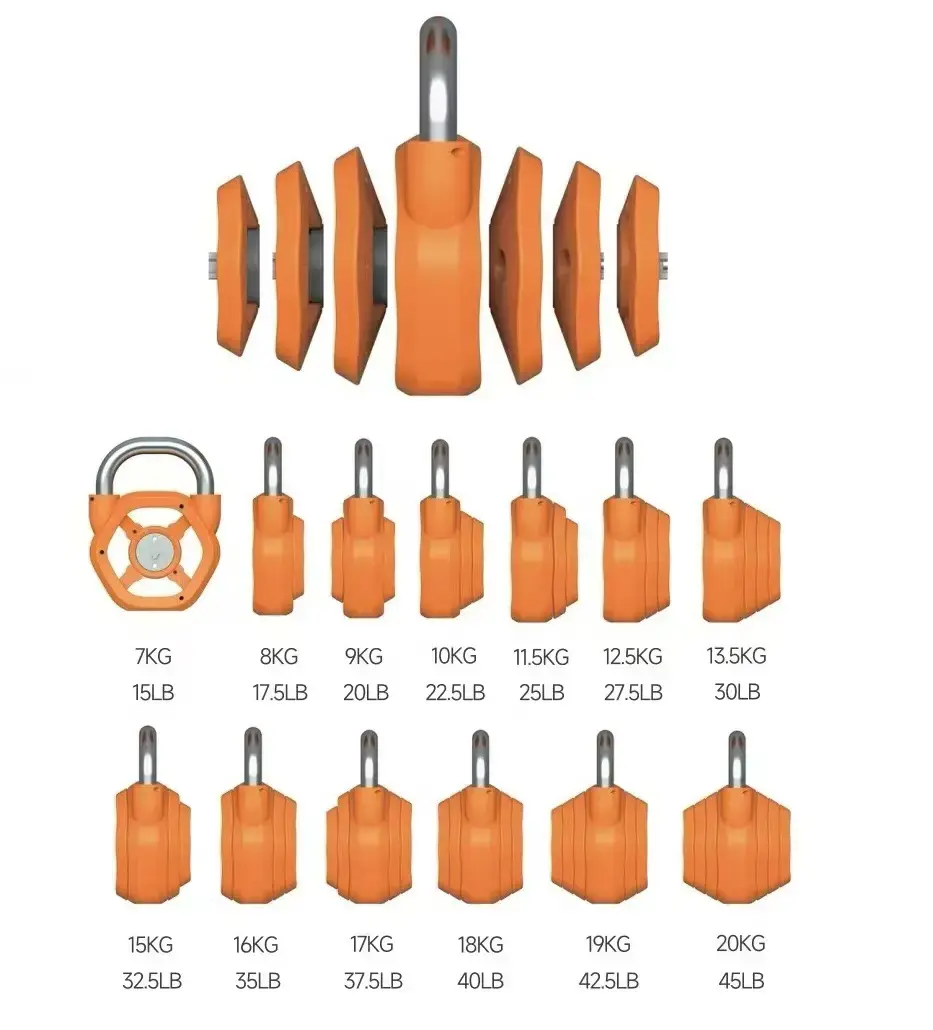

Precise weight design: The weight system of the adjustable dumbbell is one of its core parts. By accurately calculating and designing the weight of different weight plates, a combination of multiple weights can be adjusted to meet the training needs of different users. Moreover, the precise weight design can keep the dumbbells in good balance during use, avoid shaking or tilting due to uneven weight distribution, reduce adverse effects on joints and muscles, and also reduce the risk of accidental damage caused by unstable center of gravity.

Independent weight plate structure: The weight plates are designed as independent modules. Each weight plate has a certain thickness and strength, and rounded corners are used at the edges to reduce stress concentration. This structure not only allows users to flexibly increase or decrease weight according to their needs, but also reduces friction and collision between weight plates in long-term use, and is not prone to damage or deformation, which is conducive to maintaining the stability and accuracy of the weight system.

3. Ergonomic handle design

Comfortable grip shape: The handle is designed according to ergonomic principles, and its shape fits the natural curvature of the palm, allowing users to evenly distribute hand pressure when holding and reduce hand fatigue. Such a design not only improves the comfort of use, but also ensures that users can better control the dumbbells during training, reducing accidental drops or collisions caused by unstable grip, and indirectly improving the durability of the product.

Anti-slip texture treatment: Adding special anti-slip textures on the surface of the handle, such as diamond patterns, longitudinal stripes, etc., can increase the friction between the hand and the handle to prevent the dumbbells from slipping due to sweat or wet hands. Even under high-intensity training, users can hold the dumbbells firmly to avoid damage to the dumbbells due to accidental slippage, while also ensuring the safety of training.

3. Exquisite manufacturing process

1. Precision casting and processing

Automated casting technology: The use of advanced automated casting equipment can accurately control the melting temperature, pouring speed and mold forming parameters of metal materials to ensure that the cast parts have good dimensional accuracy and internal organizational structure. For example, the weight plate of the dumbbell can be guaranteed to have a regular shape, uniform thickness, and minimal weight error through the automated casting process, thereby improving the overall quality and durability of the product.

CNC finishing: For the processing of the handle, CNC machine tools are often used for high-precision processing. CNC machine tools can perform fine turning, milling, grinding and other processing procedures on the surface of the handle according to preset programs and parameters, so that the surface of the handle is smooth and the dimensional accuracy reaches the micron level. The handle that has been CNC finished is not only beautiful in appearance, but also can achieve a tighter fit when connected with the weight plate, improve the firmness and reliability of the connection, and enhance the durability of the product.

2. Strict surface treatment process

Multi-layer electroplating process: In order to improve the corrosion resistance and wear resistance of adjustable dumbbells, metal parts such as handles are usually subjected to multi-layer electroplating. First, the bottom layer is treated with anti-rust, such as zinc plating or nickel plating, to form a dense protective film to prevent the metal matrix from contacting the external environment and causing oxidation corrosion. Then, a decorative metal layer, such as chromium or copper, is plated on the basis of the bottom layer, which not only increases the beauty of the product, but also further improves the hardness and wear resistance of the surface, so that the handle is not prone to scratches, wear and other problems in long-term use, and extends the service life of the product.

Special encapsulation process: During the encapsulation process of the weight plate, a special process is used to ensure that the encapsulation is firmly bonded to the metal weight plate. For example, the surface of the metal weight plate is first pre-treated by cleaning, degreasing, and roughening, and then encapsulated with a high-strength adhesive. During the encapsulation process, the thickness, hardness, and curing time of the encapsulation are strictly controlled to ensure that the encapsulation layer is tightly combined with the metal weight plate to form a whole. In this way, even during long-term use and friction, the encapsulation is not easy to fall off or crack, maintaining good protective performance and appearance quality....

4. Strict quality control system

1. Raw material inspection

Supplier qualification review: Establish a strict supplier screening and evaluation mechanism, and only choose raw material suppliers with good reputation and production qualifications to cooperate. When selecting suppliers, conduct detailed inspections and evaluations on their production equipment, production processes, quality management systems, etc. to ensure that suppliers can provide raw materials that meet quality requirements. At the same time, regularly audit and supervise suppliers to encourage them to continuously improve and improve the quality of raw materials.

Raw material sampling and testing: Before the raw materials are put into storage, random sampling is carried out according to a certain proportion, and professional testing equipment and instruments are used to test the various performance indicators of the raw materials. For example, the mechanical properties of steel such as strength, hardness, and toughness are tested, and the composition and physical properties of the rubber laminating materials are analyzed. Only raw materials that have passed the inspection can be put into production to ensure product quality from the source.

2. Production process monitoring

Standardized production process: Develop detailed and complete production operating procedures and process documents, clearly specify the operating steps, process parameters, quality requirements, etc. of each production link, and conduct strict training for production personnel to ensure that they are familiar with and master these standards and requirements. During the production process, production personnel are required to strictly follow the standardized process to avoid product quality problems caused by human factors.

Real-time quality monitoring: Set up multiple quality inspection points on the production line, and use a combination of automated inspection equipment and manual sampling to conduct real-time quality monitoring of semi-finished products and finished products in the production process. For example, use a high-precision electronic scale to inspect the weight of the weight plate piece by piece, and use optical inspection equipment to inspect the size and surface quality of the handle. Once a quality problem is found, trace it back and deal with it immediately, and adjust the production process and parameters in time to ensure the stability and consistency of product quality.

3. Finished product quality inspection

Comprehensive functional testing: Conduct comprehensive functional tests on the finished adjustable dumbbells, including weight adjustment test, locking performance test, balance test, etc. In the weight adjustment test, check whether the dumbbells can be accurately adjusted to each weight level according to the design requirements, and whether the adjustment process is smooth and free of jamming. The locking performance test simulates various situations in actual use, such as severe shaking and bumping, to check whether the weight plate can be firmly locked on the handle without loosening or slipping. The balance test mainly detects the balance state of the dumbbell under different weight combinations to ensure that users can get a good training experience during use.

Strict durability test: In order to verify the durability of adjustable dumbbells, a series of strict durability tests are carried out. For example, the dumbbells are repeatedly dropped freely from a certain height to a hard ground to simulate the accidental fall that may occur in actual use, and the main structure, connection parts, rubber coating, etc. of the dumbbells are checked for damage, such as deformation, cracking, and shedding. At the same time, the dumbbells are tested for long-term continuous use to simulate the scene of high-intensity training of users, and the performance changes of the products after long-term use are observed, such as whether the weight is stable, whether the adjustment knob is loose, whether the handle is worn, etc. According to the test results, the products are improved and optimized to ensure that the products can meet the needs of users for long-term use.

5. Perfect after-sales service

1. Timely customer feedback processing

Establish a multi-channel feedback mechanism: Provide customers with multiple feedback channels, such as customer service hotlines, online customer service, emails, social media platforms, etc., so that customers can contact the company in time when they encounter problems or have any questions during use. Ensure that customer service staff can respond to customer inquiries and complaints in a timely manner, and carefully record customer feedback and opinions so that they can be processed and resolved in a timely manner.

Quick problem-solving process: When receiving customer feedback on the quality of adjustable dumbbells, quickly start the problem-solving process. First, conduct a detailed analysis and judgment of the problems reported by customers, and if necessary, ask customers to provide photos, videos and other relevant information of the product to understand the problem more accurately. Then, according to the nature and severity of the problem, promptly formulate solutions for customers, such as providing repairs, replacement of parts, return and exchange services, and complete the processing within the specified time to ensure customer satisfaction. At the same time, conduct in-depth investigation and analysis of the problems reported by customers, find out the causes of the problems, take corresponding measures to improve them, and avoid similar problems from happening again.

2. Active product quality tracking

Regular return visits to customers: After customers purchase adjustable dumbbells, regularly and actively communicate and return visits with customers to understand the use of the products and customer satisfaction. Ask customers whether they encounter any problems or difficulties during use, what comments and suggestions they have on the quality, performance, appearance, etc. of the products, and whether they need other support or services from the company. Through regular return visits, we can not only find potential quality problems in time, enhance customers' trust and loyalty to the brand, but also establish long-term good cooperative relations with customers and promote the sustainable development of the company.

Data analysis and quality improvement: collect and organize customer feedback information and after-sales maintenance records and other data, and use data analysis methods to evaluate and analyze product quality. By analyzing the data, we can find out the weak links and parts prone to problems of the product, and provide a basis for product improvement and optimization. According to the analysis results, formulate corresponding quality improvement plans and measures, such as improving product design, optimizing production processes, strengthening quality control, etc., to continuously improve product quality and performance, improve product durability and reliability, and meet customer needs and expectations.

6. Continuous product innovation and improvement

1. Pay attention to industry trends and technological development

Participate in industry exhibitions and seminars: actively participate in various fitness equipment industry exhibitions, seminars and technical exchange activities at home and abroad, understand the latest trends and development trends of the industry, and master cutting-edge technology and design concepts. Carry out extensive exchanges and cooperation with peer companies, scientific research institutions, experts and scholars, learn from their advanced experience and technological innovation achievements, and provide inspiration and ideas for their own product innovation.

Tracking the scientific research results of research institutions and universities: Pay close attention to the scientific research results of relevant research institutions and universities in the fields of materials science, mechanical engineering, ergonomics, etc., and apply new technological achievements to the product development of adjustable dumbbells in a timely manner. For example, the successful development of new high-strength and lightweight materials can provide better material selection for the main structure design of dumbbells, making them lighter while ensuring strength; research results in the field of ergonomics can provide a scientific basis for the design of handles and the optimization of weight systems, and improve the comfort and practicality of products.

2. User demand research and feedback

Market research and questionnaire surveys: Regularly carry out market research activities, and collect the needs and expectations of different user groups for adjustable dumbbells through questionnaires, user interviews, focus groups, etc. Understand the pain points and problems of users in actual use, such as the convenience of weight adjustment, the comfort and durability of the product, as well as their expectations and suggestions on product functions, appearance, price, etc., so that enterprises can be closer to user needs in the process of product innovation and improvement, and develop products that better meet market needs.

User usage data analysis: Use Internet technology and data analysis tools to analyze the user's behavior data and usage habits when using adjustable dumbbells. For example, by analyzing the user's choice of dumbbell weight and frequency of use at different times and in different scenarios, understand the user's main training purpose and training method, and provide a reference for product function optimization and weight configuration. At the same time, by analyzing the user's purchase behavior data, return and exchange data, etc., evaluate the market acceptance and user satisfaction of the product, and find problems and make improvements in a timely manner.

3. Continuous product optimization and upgrade

Feedback-based improvement: According to the collected industry dynamic information, user demand survey results, and after-sales feedback data, etc., the adjustable dumbbells are continuously optimized and upgraded. Targeted design improvements and process optimization are carried out for the problems and shortcomings reported by users, such as the weight adjustment is not smooth enough, the handle anti-slip effect is not good, and the rubber coating is easy to wear. For example, improve the structural design of the adjustment knob to make it easier and more accurate to adjust; use new anti-slip materials or increase the depth of the anti-slip texture of the handle to improve the anti-slip performance of the handle; improve the rubber coating process to improve the wear resistance and adhesion of the rubber coating, etc., and continuously improve the quality and performance of the product.

Functional innovation and expansion: In addition to improving existing products, we should also focus on product functional innovation and expansion to meet the increasingly diverse needs of users. For example, develop adjustable dumbbells with functions such as intelligent counting, timing, and data analysis, connect to mobile phone APP through Bluetooth or Wi-Fi technology, realize real-time monitoring and analysis of user training data, and provide users with personalized training plans and suggestions; design products with adjustable dumbbell storage racks to facilitate users to store and organize dumbbells, improve product added value and user experience, etc. Through continuous product innovation and functional expansion, adjustable dumbbells can better adapt to market changes and the development of user needs, and enhance product competitiveness and market vitality.

Conclusion

Ensuring the durability of adjustable dumbbells is a systematic project, which requires starting from material selection, structural design, manufacturing process, quality control, after-sales service, product innovation and improvement. In today's fiercely competitive international market, only companies that attach great importance to product quality and durability can win the trust and recognition of international wholesale buyers, establish long-term and stable partnerships, and thus achieve sustainable development in the fitness equipment industry. As the operator of the adjustable dumbbell independent station, product quality and durability should be regarded as the core competitiveness, and product quality should be continuously improved to provide global users with better quality and more reliable products and services.