Material and process testing of adjustable dumbbells

Material and process testing of Adjustable Dumbbells

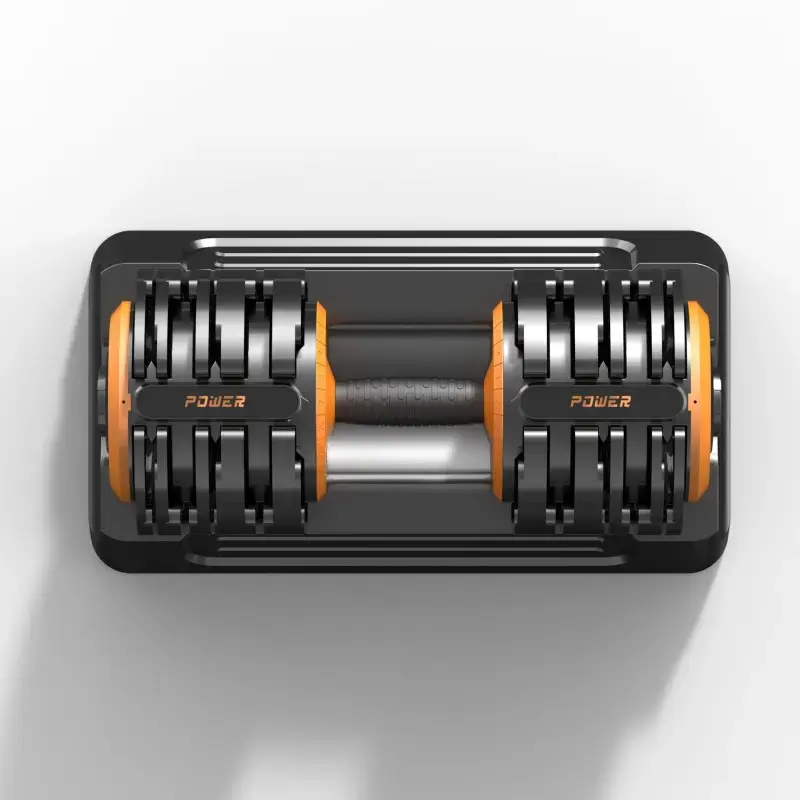

With the booming global fitness market today, adjustable dumbbells, as an efficient and flexible fitness equipment, have attracted the attention of more and more international wholesale buyers. For these professional customers, product quality, durability and safety are the factors they care about most. The guarantee of these factors is inseparable from the strict testing of adjustable dumbbell materials and processes. This article will explore in depth the material selection, process flow and related testing methods of adjustable dumbbells to help international wholesale buyers better understand the core value and quality assurance system of the product.

1. Material selection of adjustable dumbbells

(I) Steel: the cornerstone of durability

Steel is one of the most commonly used materials in adjustable dumbbells, especially for the core components of dumbbell plates and handles. Steel has high strength, high hardness and good wear resistance, and can withstand long-term high-intensity use without easy deformation or damage. For example, AtivaFit dumbbells use standard steel plates as the base material. After laser cutting, it is not only high in precision but also high in density, making the dumbbell plates smoother when shifting. In addition, the durability of steel is also reflected in its corrosion resistance. Through special surface treatment processes such as baking or electroplating, steel can be effectively prevented from rusting and the service life of the product can be extended.

(II) Cast iron: a combination of tradition and reliability

Cast iron is also a common material, especially in some mid- and low-end adjustable dumbbells. The advantages of cast iron are that it is low in cost and has good casting properties, and can produce dumbbell parts with complex shapes. However, compared with steel, cast iron is slightly inferior in strength and toughness, so in some high-end products, cast iron is usually used in combination with steel to achieve a better performance balance.

(III) Plastics and composite materials: lightweight and environmentally friendly choices

With the enhancement of environmental awareness and the advancement of technology, the application of plastics and composite materials in adjustable dumbbells has gradually increased. For example, the shell or handle of some dumbbells will use high-strength plastic or polyurethane materials. These materials are not only light in weight, but also have good corrosion resistance and impact resistance. In addition, plastics and composite materials can also achieve complex designs through processes such as injection molding, improving the appearance and ergonomics of the product.

(IV) Rubber and nylon: Improving user experience

Rubber and nylon materials are often used in the handle wrapping layer of dumbbells to provide better anti-slip effect and comfort. For example, the handle of AtivaFit dumbbells is made of solid carbon steel column, and the outside is wrapped with arc-shaped anti-slip rubber. This design not only increases the stability of holding, but also effectively reduces hand fatigue. In addition, nylon materials are also often used in the internal structure of dumbbells, such as the design of silicon steel sheet wrapped with high-strength nylon, which can not only reduce weight but also maintain good durability.

2. Manufacturing process of adjustable dumbbells

(I) Machining: Guarantee of precision and quality

Machining is an indispensable part of the manufacturing process of adjustable dumbbells, which includes cutting, drilling, turning and other processes. For example, laser cutting technology is widely used in the manufacture of dumbbell plates, which can achieve high-precision cutting effects and ensure the size accuracy and shape consistency of dumbbell plates. In addition, the use of advanced equipment such as CNC lathes can improve production efficiency and product quality and reduce human errors.

(II) Surface treatment: improving appearance and durability

The surface treatment process is crucial to the appearance and durability of adjustable dumbbells. Common surface treatment methods include baking paint, electroplating, sandblasting, etc. The baking paint process can make the surface of the dumbbell smoother and more beautiful, while also having good wear resistance and corrosion resistance. For example, AtivaFit dumbbells use a high-tech foundation baking paint process, which not only has a delicate feel and smooth and rounded edges, but also has a unique reflective effect, which improves the overall texture of the product. The electroplating process is often used in some high-end products, which can give the dumbbells a more gorgeous appearance and stronger corrosion resistance.

(III) Assembly process: ensuring functionality and safety

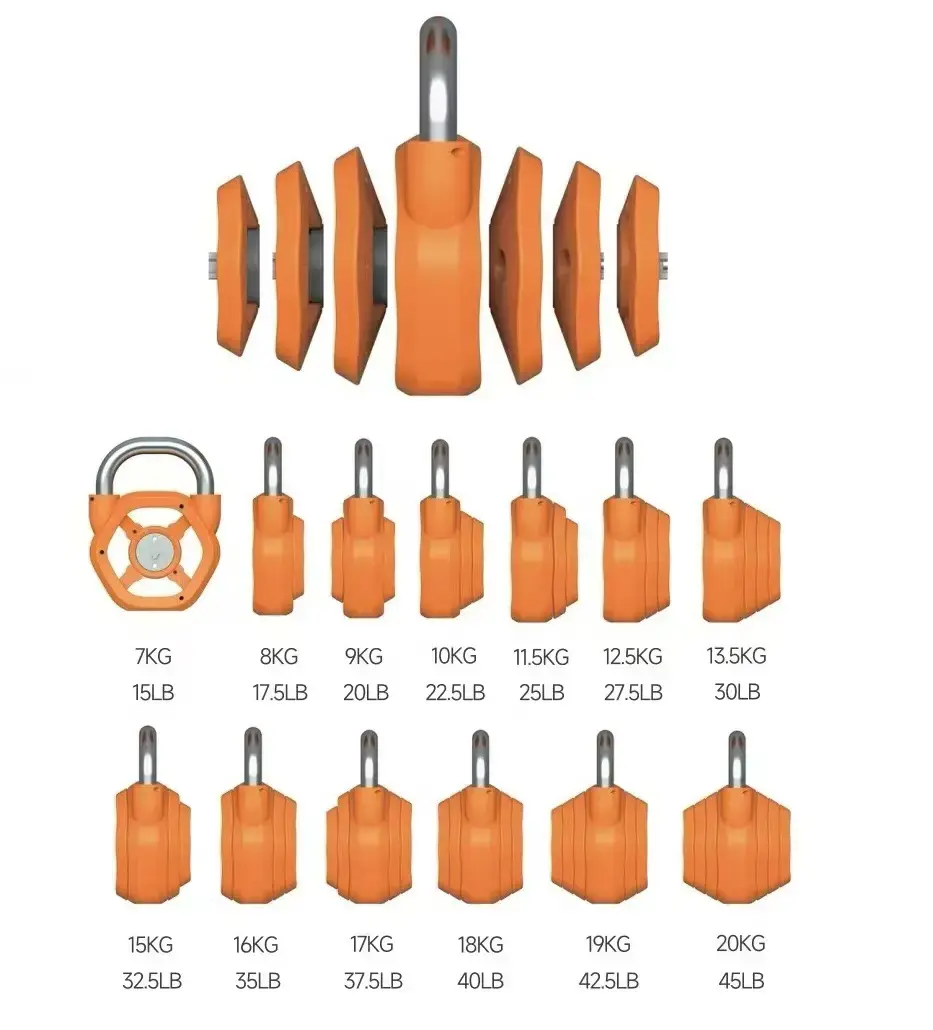

The assembly process of adjustable dumbbells directly affects their functionality and safety. For example, the design and assembly of the adjustment mechanism need to ensure that the dumbbell plates can quickly and accurately change weights, while preventing the risk of loosening or falling off during use. Some high-end products use advanced locking mechanisms, such as AtivaFit's second-generation process, which not only improves the convenience of adjustment through the design of steel sheet keel and rotating buckle, but also greatly enhances the safety of the product. In addition, the matching accuracy of parts needs to be strictly controlled during the assembly process to ensure the overall stability and service life of the dumbbells.

3. Material and process testing of adjustable dumbbells

(I) Material performance test

Strength test: Use universal material testing machines and other equipment to conduct tensile, compression and bending strength tests on materials such as steel and cast iron to ensure that the materials can withstand various stresses in normal use.

Abrasion resistance test: Use a wear tester to perform friction tests on the surface of the dumbbell plates to simulate the wear conditions in long-term use and evaluate the wear resistance of the materials.

Corrosion resistance test: Place the sample in a salt spray test chamber to simulate the corrosion conditions in a marine environment or a humid environment to test the corrosion resistance of the material.