Research on the test methods of oxidation process for the insulation performance of dumbbells

Research on the test methods of oxidation process for the insulation performance of dumbbells

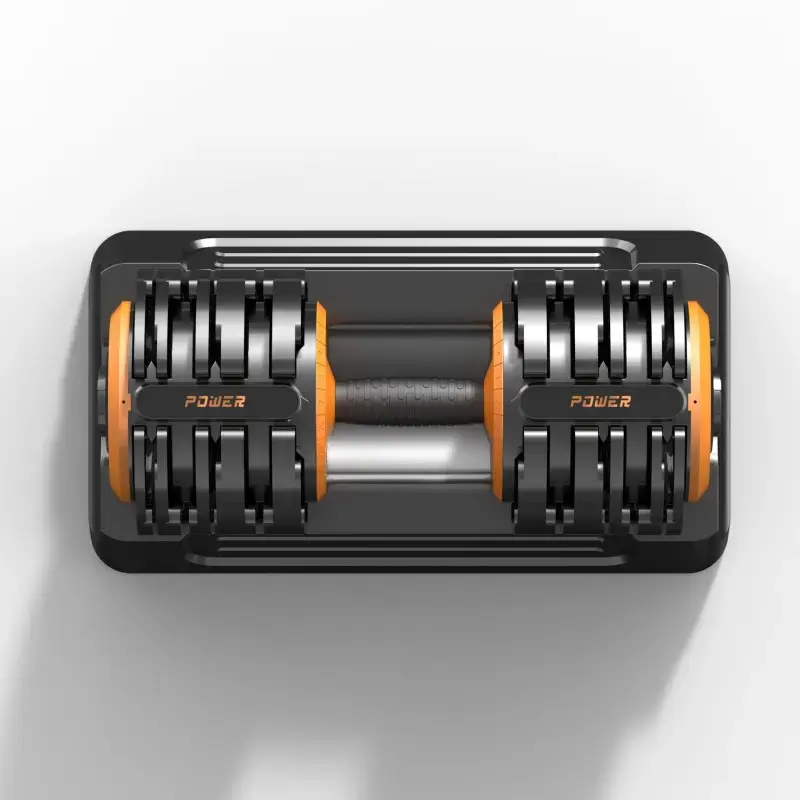

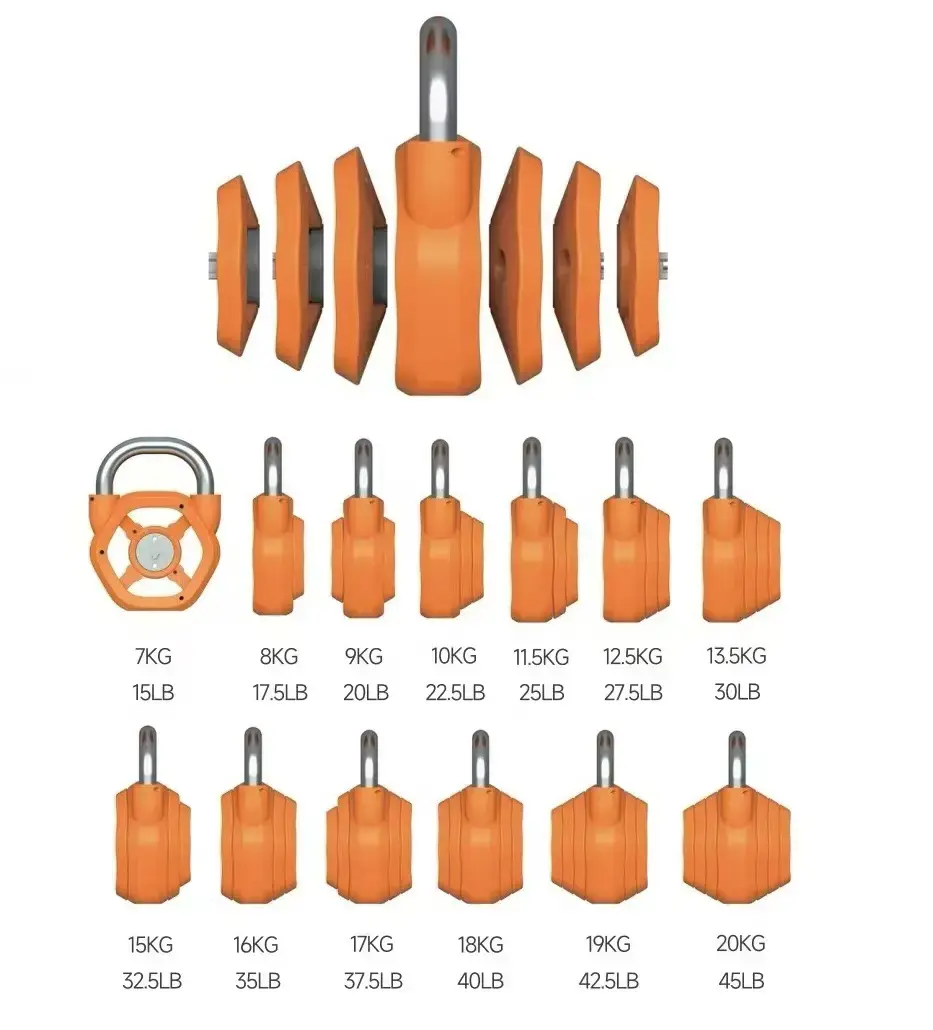

In today's global fitness equipment market, adjustable dumbbells are favored by many fitness enthusiasts because of their convenience and practicality. With the development of science and technology and industrial upgrading, oxidation process is widely used in dumbbell production to improve its insulation performance and many other quality characteristics to meet the needs of different scenarios. For international wholesale buyers, it is very important to have a deep understanding of the specific test methods of oxidation process for the insulation performance of dumbbells, which not only affects product quality control, but also affects market competitiveness and customer satisfaction. This article will deeply analyze the various test methods of oxidation process for the insulation performance of dumbbells to help buyers accurately evaluate product quality.

1. Overview of the application of oxidation process in dumbbell production

As a surface treatment technology, oxidation process can bring multi-faceted advantages to dumbbells. Its core principle is to generate a dense oxide film on the metal surface of dumbbells through a specific chemical reaction. This oxide film is like a solid barrier, which effectively prevents external moisture, oxygen and other substances from directly contacting the metal matrix, thereby giving the dumbbells strong corrosion resistance. In terms of insulation performance, the resistivity of the oxide film is relatively high, which can significantly reduce the conduction efficiency of the current on the surface of the dumbbell, reduce power loss and leakage risks, and ensure the safe use of users in special environments.

2. Key test indicators of oxide film insulation performance

(I) Insulation resistance

Insulation resistance is the basic indicator for measuring the insulation performance of the oxide film, reflecting the material's ability to block current. Higher insulation resistance means that the dumbbell can more effectively prevent the flow of charge when facing an electric field, reducing the risk of electrical breakdown. Its test usually uses a high resistance meter to apply a certain voltage to the dumbbell sample, measure the current passing through the oxide film, and then calculate the resistance value based on Ohm's law.

(II) Breakdown voltage

The breakdown voltage refers to the critical voltage required for the oxide film to break down under the action of an electric field. When the applied voltage exceeds the breakdown voltage, the insulation performance of the oxide film will be instantly lost, resulting in a sharp increase in current, which may cause a safety accident. Determining the breakdown voltage helps to clarify the safe use voltage range of the dumbbell in an electric environment and ensure that its insulation performance is stable and reliable under normal working voltage. During the test, the voltage applied to the two poles of the dumbbell is gradually increased until a sudden increase in current and a breakdown mark on the oxide film are observed. The voltage at this time is the breakdown voltage.

(III) Dielectric constant

The dielectric constant reflects the ability of the oxide film to store electric field energy. A lower dielectric constant is conducive to reducing the accumulation of electric field energy in the oxide film, reducing the possibility of electric field distortion and partial discharge, and thus improving the stability of insulation performance. Using a dedicated dielectric constant test instrument, such as an RF impedance/material analyzer, to test the dumbbell sample at a specific frequency, the dielectric constant value of the oxide film can be accurately obtained.

(IV) Tracking resistance

In harsh environments such as humidity and pollution, conductive marks are easily formed on the surface of the oxide film, gradually weakening the insulation performance. The tracking resistance test is designed to simulate such real working conditions and evaluate the ability of the oxide film to resist the formation of electric marks. According to relevant standards, the dumbbell sample is placed in a conductive solution dripping device, and the conductive liquid is continuously dripped while applying a specified voltage. The time from the formation of electric marks on the surface of the oxide film to the destruction is observed and recorded. The longer the time, the better the tracking resistance.

III. Detailed explanation of the test method for the effect of oxidation process on the insulation performance of dumbbells

(I) Electrochemical impedance spectroscopy test

Electrochemical impedance spectroscopy (EIS) is an in-situ, non-destructive electrochemical test method that can deeply explore the electrochemical properties of the oxide film and indirectly reflect its insulation performance. During the test, the dumbbell sample is used as the working electrode, and together with the reference electrode and the auxiliary electrode, it forms a three-electrode system and is connected to the electrochemical workstation. Under the excitation of a small AC signal, the impedance response of the oxide film at different frequencies is measured. By analyzing the Nyquist diagram and Bode diagram in the impedance spectrum, the key electrical parameters such as resistance and capacitance of the oxide film can be obtained, and then the quality of its insulation performance can be evaluated. For example, a larger impedance modulus means that the oxide film has a stronger barrier effect on ion migration and better insulation performance. At the same time, by observing the changes in the characteristic peaks in the spectrum, it can also provide insight into the mechanism of the influence of the microstructural characteristics of the oxide film, such as defects and pores, on the insulation performance.

(II) Tensile test

Although the tensile test is mainly used to analyze the mechanical properties of materials, it can also indirectly reflect the effect of the oxidation process on the insulation performance of dumbbells through the design of a specific test scheme. When the dumbbell is subjected to tensile stress, the microstructure of the oxide film will change, such as microcracks and local deformation, which will change the insulation properties of the oxide film. A universal material testing machine is used to apply tensile force to the dumbbell sample and record its stress-strain curve during the stretching process. By observing the characteristics of the curve, such as yield strength, elongation at break, etc., combined with the test results of the electrical properties of the oxide film, the influence of tensile deformation on the insulation properties of the oxide film can be studied. For example, if the insulation resistance of the oxide film decreases significantly during the stretching process, it means that the tensile stress may have destroyed the dense structure of the oxide film, resulting in the degradation of the insulation performance.

(III) Withstand voltage test

Withstand voltage test is one of the effective methods to directly evaluate the insulation properties of the oxide film. Place the dumbbell sample between two electrodes, slowly increase the applied voltage until the predetermined test voltage value is reached, and maintain it for a certain time to observe whether the oxide film has abnormal phenomena such as breakdown and flashover. If the oxide film does not break down within the specified time and the leakage current remains at an extremely low level, it indicates that the oxide film has good insulation properties and electrical strength.