Telescopic Rod Lock: The Secret of Adjustable Dumbbell Stability

Telescopic Rod Lock: The Secret of Adjustable Dumbbell Stability

Introduction

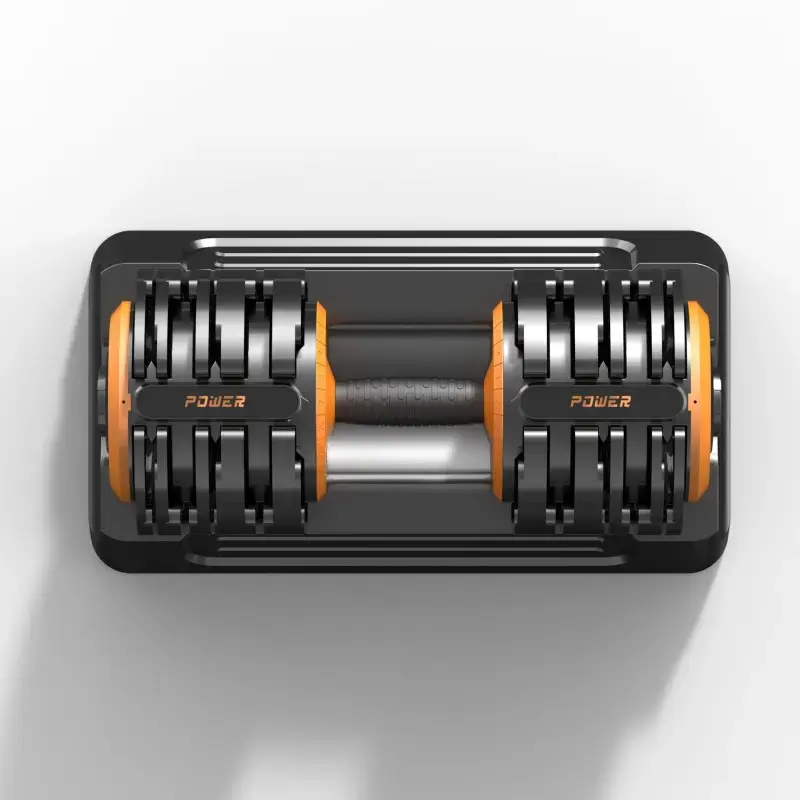

In today's fitness equipment market, adjustable dumbbells are popular for their convenience and versatility. For international wholesale buyers, product quality and safety are crucial considerations. One of the key technologies of Adjustable Dumbbells, the telescopic rod lock, plays a vital role in preventing the dumbbell plates from loosening. This article will explore the principles and advantages behind it.

1. Basic Principles of Locking Pieces

Mechanical Locking Concept: The locking piece is usually a specific device installed on the telescopic rod. When the telescopic rod is extended or retracted to the set position, the locking piece will be stuck in the locking groove or bayonet of the corresponding part of the dumbbell plate or grip. For example, the common spring locking device, under the action of external force, the spring is compressed to make the locking piece enter the working position. Once the external force is eliminated, the elastic rebound force of the spring pushes the locking piece tightly into the locking groove, forming a stable mechanical lock, preventing the relative displacement between the dumbbell plate and the telescopic rod.

Friction-assisted fixation: In addition to pure mechanical engagement, the close contact between the locking piece and the locking slot will also generate a certain amount of friction. This friction further increases the stability of the connection, making it difficult for the dumbbell plate to loosen due to inertia, external force and other factors during exercise. Just like two tightly fitted wooden boards, in addition to the fixation of nails (similar to mechanical locking), the friction between the wooden boards also plays an auxiliary fixing role.

2. Exquisite structural design

Multi-point locking and distributed force: The advanced locking piece system adopts a multi-point locking design. Multiple locking pieces are distributed at different positions on the telescopic rod, which can be inserted into the locking slots of multiple dumbbell plates or grips at the same time. This design distributes the force to multiple points to avoid excessive stress at a single point and cause locking failure. For example, if a locking piece bears a force of 10 Newtons, each of the four locking pieces only needs to bear 2.5 Newtons, which greatly reduces the burden of each locking piece and improves the overall stability.

Adaptive adjustment structure: Some locking pieces have adaptive adjustment function. When encountering dumbbell plate lock slots of different thicknesses and shapes, the locking piece can automatically adjust its own engagement method and strength. The elastic element or movable joint structure inside allows the locking piece to move flexibly within a certain range, ensuring that no matter how the dumbbell plate changes, it can achieve tight and stable locking.

3. Ensure connection reliability

Material and manufacturing process: The manufacturing material of the locking piece is crucial. High-quality materials such as high-strength alloy steel are used, and after precise forging, heat treatment and machining processes, it has sufficient hardness and toughness. Hardness ensures that the locking piece is not easy to wear and deform during frequent engagement and friction, while toughness prevents it from breaking when subjected to large impact forces. For example, the surface hardness of the alloy steel locking piece that has been quenched can reach a certain standard, effectively resisting wear and impact.

Strict testing and quality control: Before mass production, the locking piece will undergo a series of strict quality tests, including durability tests, tension tests, vibration tests, etc. Simulate various actual use scenarios, such as long-term high-intensity training, frequent weight adjustment, etc., to ensure that the locking parts can reliably prevent the dumbbells from loosening under various harsh conditions. Only the locking parts that have passed these harsh tests will be used in adjustable dumbbell products.

4. Improve the safety and convenience of use

Safety guarantee: The most direct significance of preventing the dumbbells from loosening is to ensure the safety of users. In fitness training, especially during high-intensity strength training, if the dumbbells suddenly loosen, it will not only interrupt the training, but also may cause injuries to the user. Reliable locking parts ensure that users can use adjustable dumbbells with peace of mind throughout the training process, give full play to their training effects, and do not need to worry about safety issues.

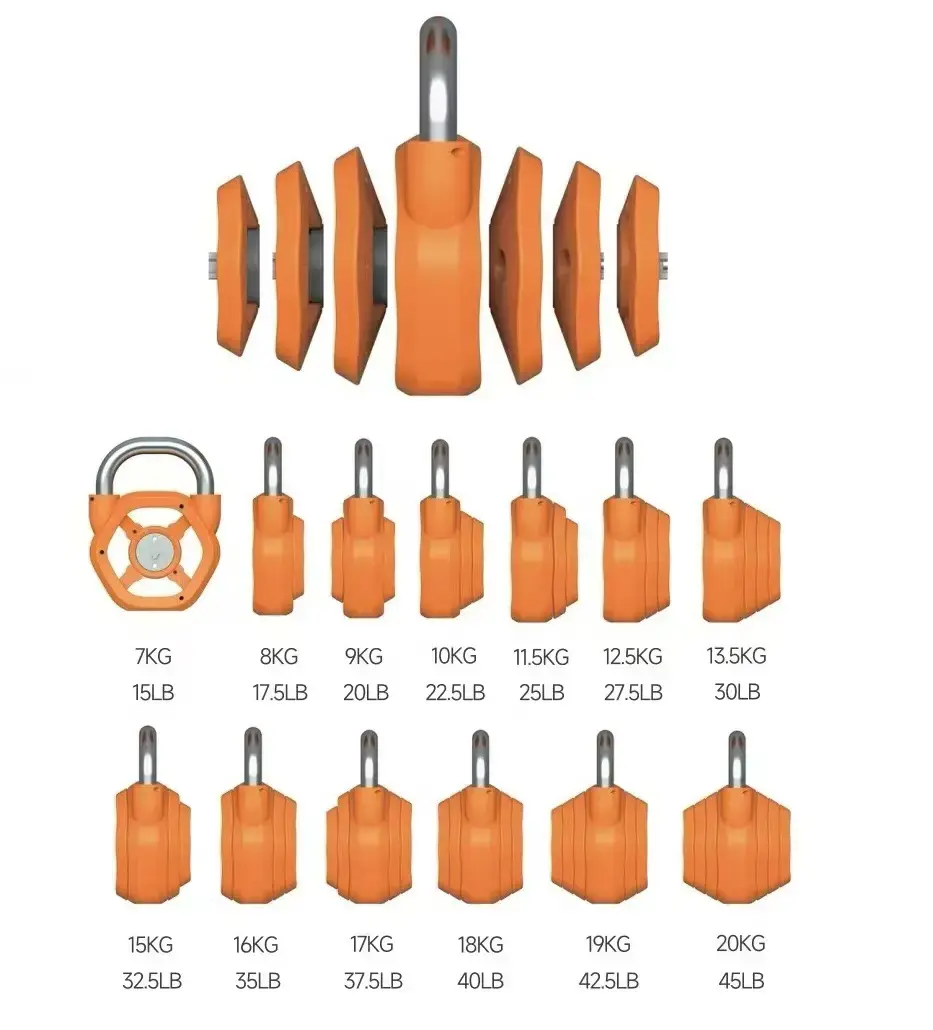

Convenient adjustment and use experience: A good locking part design can also improve the convenience of users. When the user needs to adjust the weight of the dumbbell, it can be easily unlocked and re-locked with simple operations, without the effort of disassembling and installing multiple complex parts. For example, some locking parts are equipped with a one-touch unlocking button or a knob-type unlocking device. The user only needs to press or turn it lightly to quickly complete the weight adjustment, improving the training efficiency and use experience.

5. Advantages of traditional fixing methods

Flexibility and adaptability: Compared with traditional fixed-weight dumbbells, the locking-type fixing method of adjustable dumbbells has extremely high flexibility and adaptability. Once the weight of traditional dumbbells is determined, it is difficult to change, and users need to buy multiple sets of dumbbells of different weights to meet different training needs. With the combination of telescopic rods and locking parts, users only need one set of products to quickly switch between multiple weights, saving space and cost, and at the same time better adapting to the personalized training needs of different users.

Convenience of upgrade and maintenance: The locking-type fixing method is convenient for upgrading and maintaining dumbbells. If the locking part is worn or damaged, users can replace it with a new one relatively easily without replacing the entire dumbbell. In contrast, once the dumbbells with traditional fixing methods are damaged, they can only be scrapped as a whole or undergo complex repairs, which is costly and inconvenient to operate.

6. Actual application scenarios and case analysis

Fitness clubs: In large fitness clubs, adjustable dumbbells are widely used because of their advantages such as saving space and convenient management. The locking parts of the telescopic rod have been tested for a long time and high intensity, and can still stably prevent the dumbbells from loosening. For example, after a well-known chain fitness brand introduced a certain adjustable dumbbell, after half a year of high intensity use, there was no safety accident caused by the loose dumbbells, which was well received by members and coaches.

Home fitness scene: For home users, the locking part fixing method of adjustable dumbbells is also very attractive. Home fitness space is usually limited, and adjustable dumbbells can meet the needs of family members of different ages and different fitness levels. A fitness enthusiast shared his experience of using it. He bought a set of adjustable dumbbells for home fitness. After more than two years of use, the locking parts can still tightly fix the dumbbells, allowing him to perform effective strength training at any time.

7. Future development trends and innovation directions

Intelligent locking system: With the continuous advancement of technology, intelligence will become one of the development trends of adjustable dumbbell locking parts. Future locking parts may integrate sensors and microprocessors to automatically sense the movement state of the dumbbells and the user's operating intentions. For example, when the user lifts the dumbbell to start training, the locking piece will automatically strengthen the locking force; when the user puts down the dumbbell and leaves for a certain period of time, the locking piece will automatically enter a low-power standby mode while maintaining sufficient locking strength.

More efficient materials and structural innovations: Researchers will continue to explore and develop higher-performance materials and more efficient locking structures. The application of new composite materials is expected to further reduce the weight of the locking piece while maintaining high strength and improve its performance. At the same time, the principles of interdisciplinary fields such as bionics may be introduced into the design of the locking piece, drawing on the exquisite structure and function of natural organisms to create more innovative and reliable locking pieces.

Conclusion

The locking piece of the telescopic rod plays a vital role in the adjustable dumbbell. It effectively prevents the dumbbell pieces from loosening through clever mechanical principles, careful structural design and strict quality control, providing users with a safe and reliable fitness experience.