The Comprehensive Guide to Surface Treatment Processes for Adjustable Dumbbells

Introduction

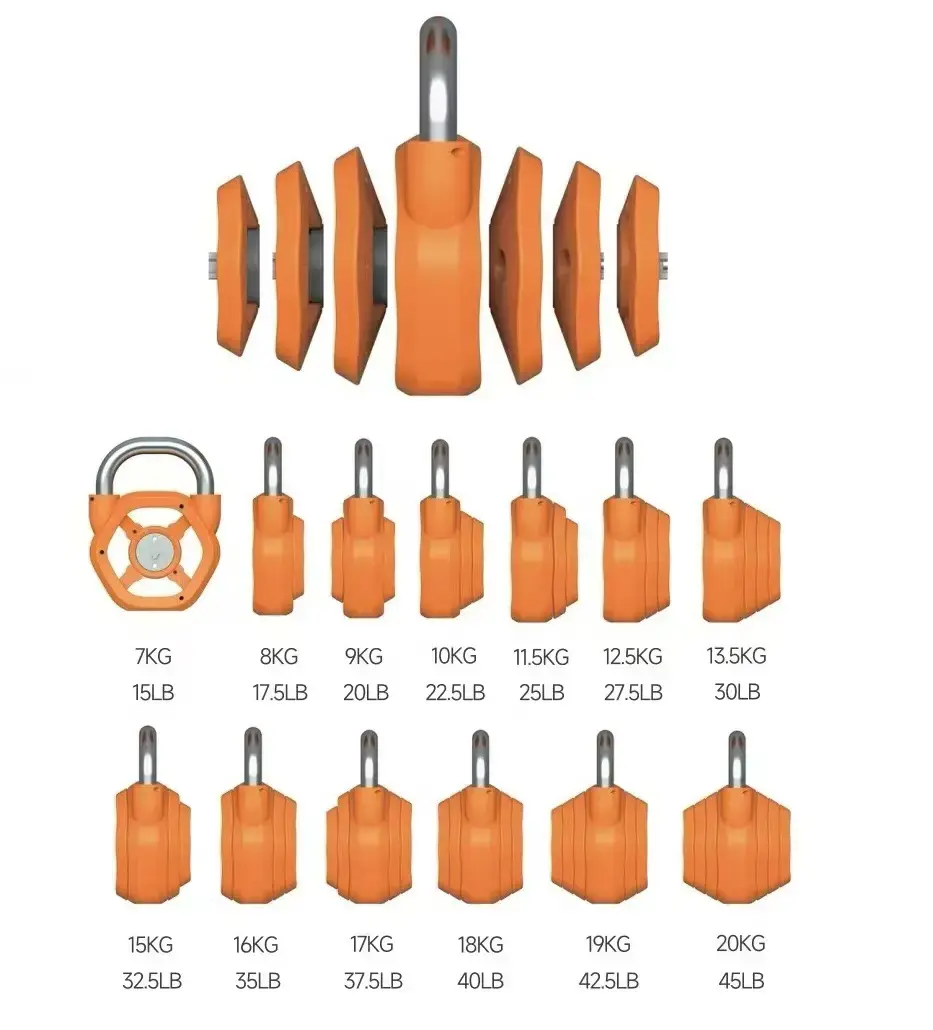

In the global fitness market, adjustable dumbbells have become increasingly popular due to their convenience and efficiency for strength training. As the market continues to grow, international wholesale buyers need to understand the various surface treatment processes for Adjustable Dumbbells. These processes not only affect the product's quality and lifespan but also its market competitiveness and customer satisfaction. This blog post will delve into the different surface treatment processes used for adjustable dumbbells, providing a detailed guide for wholesale buyers.

Overview of Surface Treatment Processes

Surface treatment is a crucial step in the manufacturing of adjustable dumbbells. It enhances the wear resistance, corrosion resistance, and overall appearance of the product. Proper surface treatment can significantly extend the product's lifespan and improve its market value.

Electroplating Process

Electroplating is one of the most common surface treatment methods for adjustable dumbbells. It involves using electrolysis to deposit a layer of metal, such as zinc, nickel, or chromium, onto the surface of the dumbbell. This process provides excellent corrosion resistance and a decorative finish.

Steps in the Electroplating Process

Pretreatment:

Degreasing: The dumbbell is soaked in an alkaline degreasing agent to remove oils and impurities. This is followed by a water rinse to remove any residual degreasing agent.

Pickling: To remove rust or scale, the dumbbell is immersed in an acid solution. After pickling, it is rinsed again to remove any remaining acid.

Electroplating:

Pre-plating: A thin layer of metal, such as zinc or nickel, is applied to improve the bonding strength between the plating and the base metal.

Main Plating: The main plating layer is applied based on the desired properties. For example, chromium plating offers excellent wear resistance.

Post-treatment:

Passivation: The plating is treated with a passivation solution to enhance its corrosion resistance.

Drying: The passivated dumbbell is dried to remove moisture and prevent water stains.

Spraying Process

The spraying process involves applying a special coating to the surface of the dumbbell using a spraying device. This method allows for a wide range of colors and finishes to meet different consumer preferences.

Steps in the Spraying Process

Surface Pretreatment:

Polishing: The surface is polished to remove burrs and scratches, ensuring a smooth finish.

Degreasing and Rust Removal: Chemical degreasers or rust removers are used to clean the surface, followed by a water rinse.

Spraying:

Coating Selection: The coating is chosen based on its adhesion, wear resistance, and decorative properties.

Spraying Equipment and Parameter Settings: Professional spraying equipment is used to apply the coating evenly. The thickness of the coating is typically controlled to be between 50-100μm.

Curing: The coated dumbbell is placed in an oven to cure the coating, which forms a solid protective layer.

Oxidation Process

For adjustable dumbbells made from aluminum alloy, oxidation treatment is an effective surface treatment method. It involves forming an oxide film on the surface through chemical reactions, enhancing the hardness, wear resistance, and corrosion resistance of the material.

Steps in the Oxidation Process

Pretreatment:

Degreasing: Similar to the electroplating process, the surface is degreased using an alkaline solution.

Alkali Etching: The surface is etched with an alkaline solution to remove defects and prepare it for oxidation.

Neutralization: The surface is neutralized to prevent excessive alkaline reactions.

Oxidation Treatment:

Anodizing: The aluminum alloy is used as the anode in an electrolyte solution, forming a dense oxide film on the surface.

Sealing: The oxide film is sealed to improve its durability and resistance to corrosion.

Comparison of Surface Treatment Processes

Different surface treatment processes offer various advantages and disadvantages. Here is a comparative analysis of the electroplating, spraying, and oxidation processes.

Feature Electroplating Process Spraying Process Oxidation Process

Wear Resistance Excellent Good Moderate

Corrosion Resistance Excellent Good Moderate

Hardness and Strength High Low Moderate

Metal Texture Strong Simulated Unique

Texture Effect Smooth Customizable Unique

Maintenance Cost High High Low

Life Cost High High Low

Quality Control in Surface Treatment

Quality control is essential in ensuring the effectiveness and longevity of surface treatments. Here are some key aspects to consider:

Raw Material Quality Control

Metal Material Selection: High-purity metals are used for electroplating to ensure quality and performance.

Coating Quality: For the spraying process, coatings that meet environmental standards and have stable performance are crucial.

Alloy Composition Control: The composition of aluminum alloys must be precisely controlled to achieve the desired properties during oxidation treatment.

Process Parameter Control

Electroplating Solution Composition: Regular testing and adjustment of the electroplating solution are necessary to maintain optimal conditions.

Spraying Parameters: The spraying equipment settings, such as pressure and nozzle size, must be carefully adjusted to ensure even coating application.

Oxidation Parameters: The voltage, current density, and processing time during anodizing must be strictly controlled to achieve the desired oxide film thickness and properties.

Development Trends in Surface Treatment

The surface treatment industry is constantly evolving, driven by environmental regulations, technological advancements, and changing consumer demands. Here are some key trends to watch:

Environmental Sustainability

Chromium-Free Electroplating: This process reduces or eliminates the use of heavy metals, minimizing environmental impact.

Water-Based and High-Solid Paints: These eco-friendly coatings are increasingly used in the spraying process to lower VOC emissions.

Multifunctional Composite Treatments

Combined Processes: Techniques such as combining electroplating with chemical conversion treatments or spraying with micro-arc oxidation are being developed to enhance performance and functionality.

Intelligent Production Lines

Automation and Control: Advanced automation equipment and intelligent control systems are being implemented to improve production efficiency, reduce labor costs, and ensure consistent product quality.

Personalization

Customized Designs: The ability to create unique patterns, logos, and color combinations through surface treatment processes is becoming more prevalent, catering to the growing demand for personalized products.

Conclusion

The surface treatment process for adjustable dumbbells is a critical factor in determining the product's quality, appearance, and market value. Understanding the different processes, their advantages, and quality control measures is essential for international wholesale buyers. By staying informed about the latest trends and developments in surface treatment, buyers can make informed decisions and select suppliers with advanced technologies and strict quality control systems. This will help them meet the evolving needs of their customers and stay competitive in the global market.