The Durability and Fatigue Testing of Adjustable Dumbbells

The Durability and Fatigue Testing of Adjustable Dumbbells

Introduction

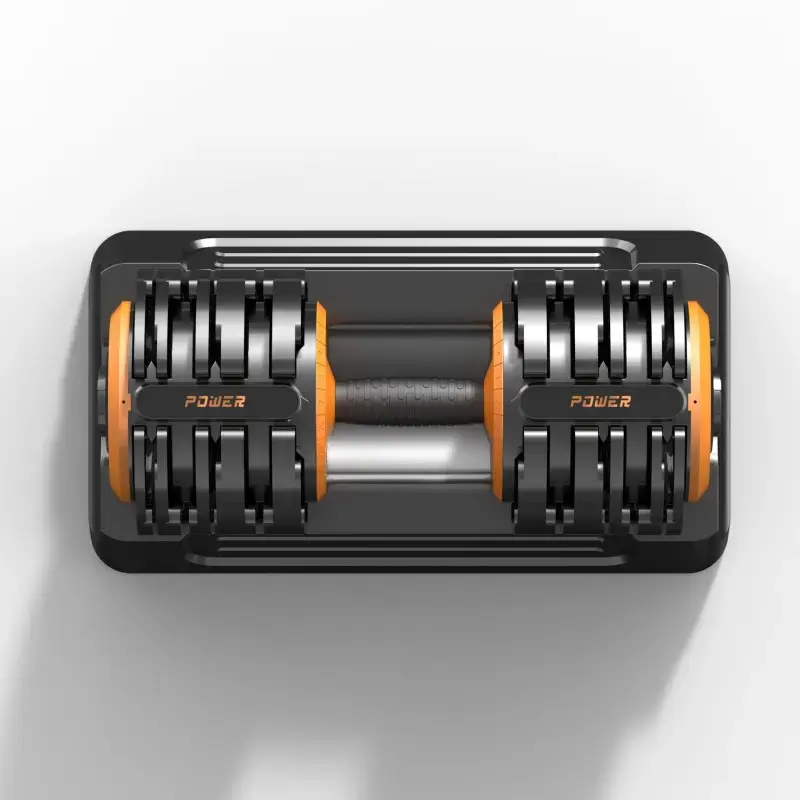

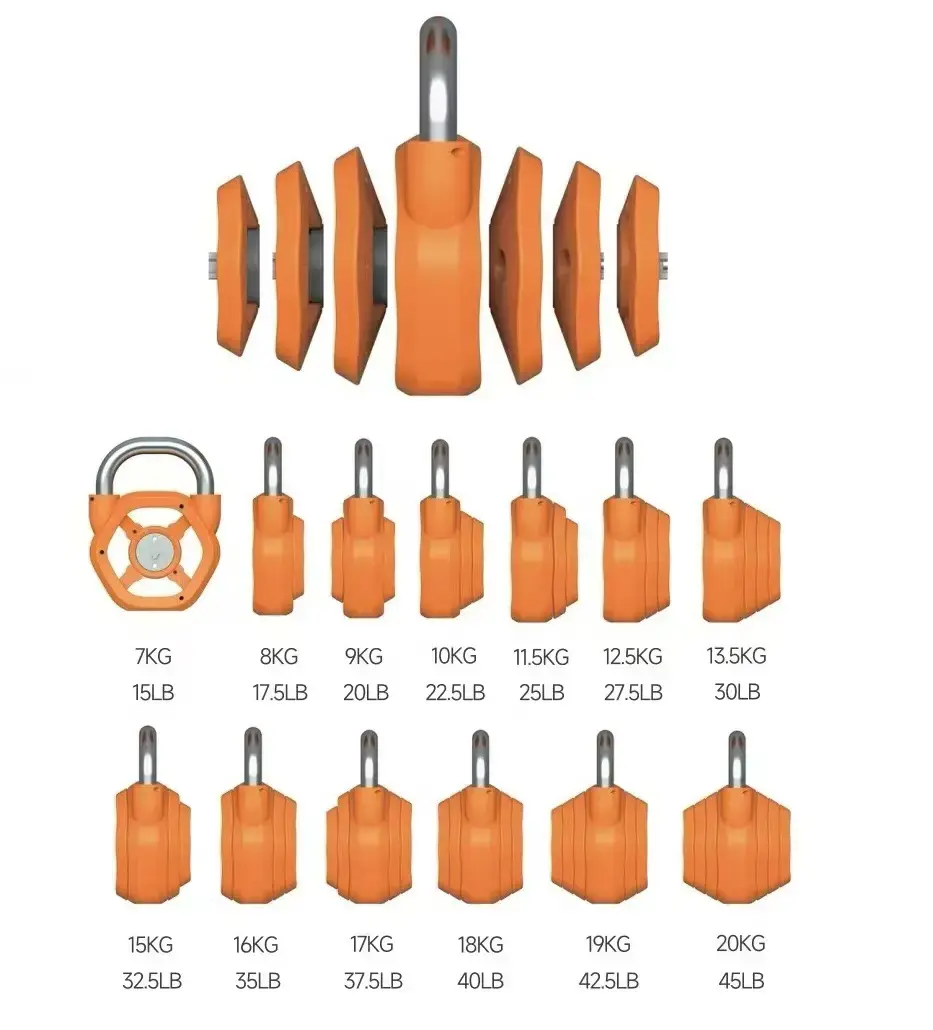

Adjustable dumbbells have become increasingly popular among fitness enthusiasts and professional athletes due to their versatility and convenience. These dumbbells allow users to easily adjust the weight according to their training needs, making them a valuable addition to any workout routine. However, ensuring the durability and fatigue resistance of adjustable dumbbells is crucial for their long-term performance and user safety. This article delves into the comprehensive testing methods and standards used to evaluate the durability and fatigue resistance of adjustable dumbbells, providing valuable insights for global wholesale professional buyers.

Importance of Durability and Fatigue Testing

Durability and fatigue testing are essential for assessing the long-term performance of adjustable dumbbells. These tests simulate the repeated use and stress that the dumbbells will endure during regular training sessions. By conducting thorough testing, manufacturers can identify potential weaknesses and improve the design and materials used in the production of adjustable dumbbells. This not only enhances the product's lifespan but also ensures user safety by reducing the risk of failure during use.

Fatigue Testing Methods

1. Fatigue Life Testing

Fatigue life testing is a critical component of evaluating the durability of adjustable dumbbells. This test involves subjecting the dumbbells to repeated cycles of loading and unloading to simulate the stress they will experience during prolonged use. The goal is to determine the number of cycles the dumbbells can withstand before failure occurs. This test helps in understanding the material's resistance to cyclic loading and provides valuable data for predicting the product's lifespan.

2. Dynamic Load Testing

Dynamic load testing assesses the performance of adjustable dumbbells under varying load conditions. This test simulates the actual usage scenario where the dumbbells are subjected to different weights and movements. By analyzing the dumbbells' behavior under dynamic loads, manufacturers can ensure that the product remains stable and reliable during intense workouts.

3. Cycle Testing

Cycle testing involves repeated loading and unloading cycles to evaluate the dumbbells' ability to withstand repetitive stress. This test is particularly important for adjustable dumbbells, as they are frequently adjusted and used in various exercises. The cycle test helps in identifying any potential weaknesses in the design or materials that may lead to failure over time.

Durability Testing Methods

1. Drop Testing

Drop testing evaluates the structural integrity of adjustable dumbbells when subjected to accidental falls. This test simulates real-life scenarios where the dumbbells may be dropped during use or storage. By assessing the impact resistance of the dumbbells, manufacturers can ensure that they remain functional and safe even after unexpected drops.

2. Wear and Tear Testing

Wear and tear testing assesses the durability of the dumbbells' surface and components over time. This includes evaluating the resistance of the coating to scratches, abrasions, and corrosion. The test also examines the durability of the adjustable mechanisms and connections to ensure they remain reliable and functional throughout the product's lifespan.

3. Environmental Testing

Environmental testing evaluates the dumbbells' performance under various environmental conditions, such as temperature extremes, humidity, and exposure to sunlight. This test helps in understanding how the materials used in the dumbbells will react to different environmental factors, ensuring that the product remains durable and reliable in diverse settings.

Testing Standards and Protocols

1. ASTM Standards

The ASTM (American Society for Testing and Materials) standards provide guidelines for conducting durability and fatigue tests on various materials and products. For adjustable dumbbells, relevant ASTM standards include ASTM D412 for elastomer testing, ASTM D638 for plastic testing, and ASTM D3039 for composite material testing. These standards outline the specific test methods, sample preparation, and data analysis procedures to ensure consistent and reliable results.

2. EN 957

EN 957 is a European standard that specifically addresses the safety and durability of fitness equipment, including adjustable dumbbells. This standard includes various tests such as static load testing, dynamic load testing, and stability testing. It also provides guidelines for evaluating the durability of components such as handles, weights, and adjustment mechanisms. By adhering to EN 957, manufacturers can ensure that their adjustable dumbbells meet the highest safety and performance standards.

Case Studies and Real-World Applications

Case Study 1: Ergonomic Adjustable Dumbbells

A leading fitness equipment manufacturer conducted extensive durability and fatigue testing on their new line of ergonomic adjustable dumbbells. The testing included cycle testing, drop testing, and environmental testing to evaluate the dumbbells' performance under various conditions. The results showed that the dumbbells could withstand over 100,000 cycles of use without significant wear or damage. The ergonomic design also ensured a comfortable grip, reducing the risk of hand fatigue during prolonged use.

Case Study 2: High-Performance Adjustable Dumbbells

Another manufacturer focused on developing high-performance adjustable dumbbells for professional athletes. The durability and fatigue testing involved subjecting the dumbbells to extreme conditions, including high-frequency loading cycles and exposure to harsh environmental factors. The testing revealed that the dumbbells maintained their structural integrity and functionality even after extensive use. The manufacturer used this data to refine the product design, resulting in a durable and reliable adjustable dumbbell suitable for high-intensity training.

Conclusion

Durability and fatigue testing are indispensable for ensuring the long-term performance and safety of adjustable dumbbells. By employing rigorous testing methods and adhering to established standards, manufacturers can develop products that meet the demands of professional athletes and fitness enthusiasts alike.