The influence of oxidation process on the insulation performance of dumbbells

The influence of oxidation process on the insulation performance of dumbbells

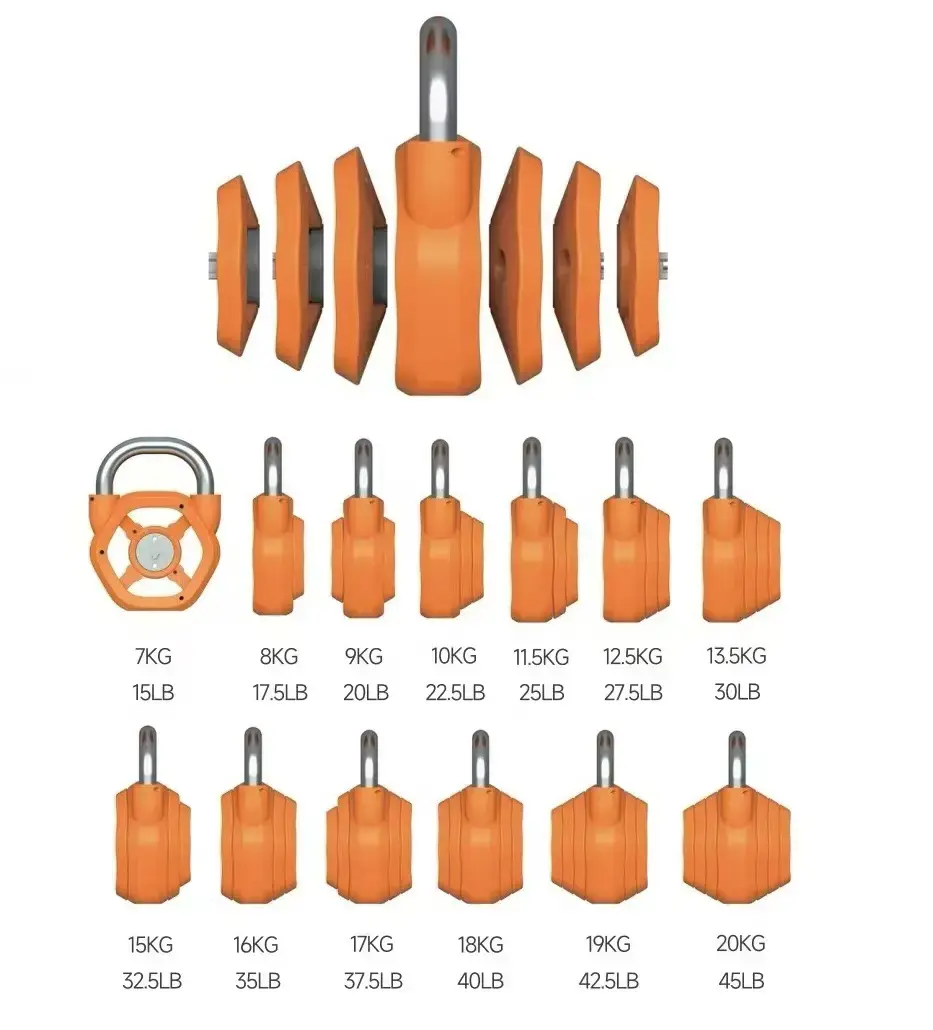

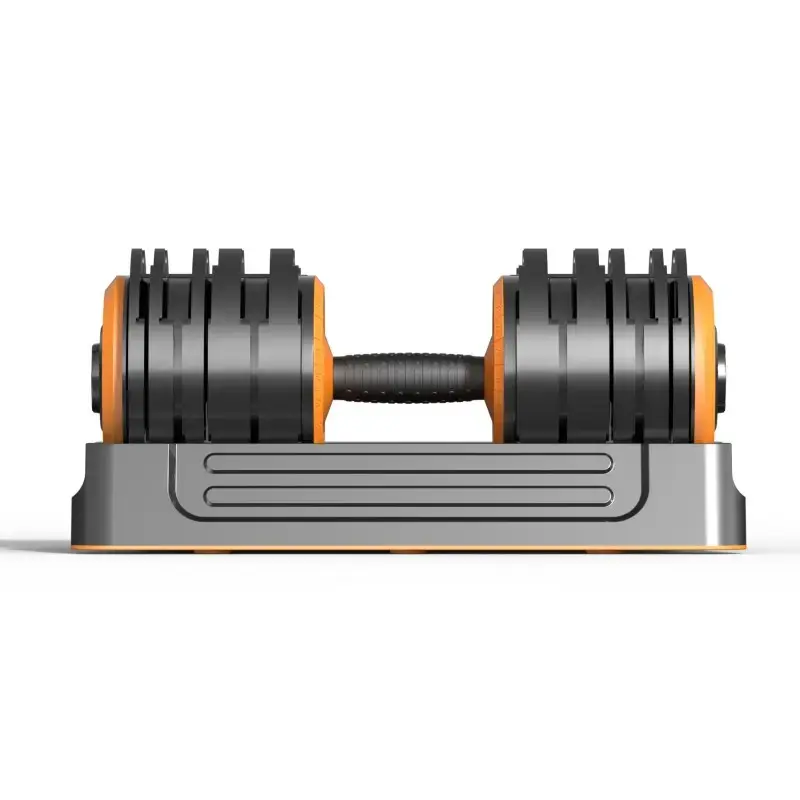

In the field of fitness equipment, adjustable dumbbells are favored by the market because of their convenience and practicality, and their insulation performance is related to user safety and product life. As an important means to improve the insulation performance of dumbbells, the oxidation process has far-reaching significance for the overall quality of the product. The following is an in-depth discussion on the influence of oxidation process on the insulation performance of dumbbells.

1. Principle of oxidation process

The oxidation process is a technology that generates an oxide film on the metal surface through chemical reaction. Taking the common anodic oxidation as an example, the metal product is used as the anode, and the current is applied in the electrolyte solution. The metal ions on the metal surface react with the oxygen ions in the electrolyte to form a metal oxide, that is, an oxide film. This oxide film has a dense structure, high resistivity and good dielectric properties, which can effectively prevent the current from passing through, thereby improving the insulation of the metal surface.

2. The positive influence of oxidation process on the insulation performance of dumbbells

Improving insulation resistance: The oxide film is mainly composed of metal oxides, and the electron transfer between the oxygen ions and the metal ions is blocked, and the electrons are difficult to move freely, which makes the oxide film present a high resistivity. When the oxidation process parameters are reasonable, the generated oxide film has a moderate thickness and a uniform and dense structure, which can further increase the resistance of current propagation on the metal surface, effectively improve the insulation resistance of the dumbbell, reduce the risk of current leakage, and ensure the safety of users during use.

Reduce dielectric loss: The oxide film has a high dielectric constant and low dielectric loss. Under the action of the electric field, the oxide film can reduce the loss of electric energy during the propagation process and improve the efficiency of electric energy transmission. For Adjustable Dumbbells, good insulation performance can prevent the waste of electric energy and extend the service life of batteries or power supplies. At the same time, it can reduce the heat generation caused by dielectric loss and avoid safety hazards caused by overheating.

Suppress surface discharge: The high insulation performance and uniformity of the oxide film can effectively reduce the electric field concentration and charge accumulation on the metal surface. In actual use, if the metal parts of the adjustable dumbbell are exposed to the electric field, it is easy to produce discharge due to surface charge accumulation, damage the product insulation layer, and even cause safety accidents. The oxide film formed by the oxidation process can evenly cover the metal surface, balance the electric field distribution, suppress surface discharge, and ensure the stable operation of the product.

Improve the breakdown voltage: The high insulation performance of the oxide film gives it a higher breakdown voltage. Under the action of a strong electric field, the oxide film can withstand higher voltages without being broken down, thereby improving the electrical strength of the dumbbell. For some special application scenarios, such as adjustable dumbbells in medical rehabilitation equipment or industrial fitness facilities, a higher insulation level is required to cope with complex electromagnetic environments. The oxidation process can meet this demand and ensure the reliability of the product under high voltage conditions.

3. The influence of oxidation process parameters on insulation performance

Oxidation time: Oxidation time is a key factor affecting the thickness and performance of the oxide film. Within a certain range, as the oxidation time increases, the thickness of the oxide film increases and the insulation performance improves. However, too long an oxidation time may cause the oxide film to be too thick, increase the internal stress of the film layer, make the film layer loose and porous, and reduce the insulation performance. Therefore, it is necessary to determine the optimal oxidation time according to the metal material and use requirements of the dumbbell to obtain a uniform, dense oxide film with excellent insulation performance.

Oxidation temperature: The oxidation temperature has a significant effect on the growth rate and structure of the oxide film. If the temperature is too high, the oxide film will grow too fast, which may lead to uneven and loose film structure, defects and reduced insulation performance; if the temperature is too low, the oxidation reaction rate will be slow, the oxide film generation efficiency will be low, and it will be difficult to meet production needs. Generally, the anodizing temperature is controlled between 15℃-30℃, and the specific temperature needs to be optimized in combination with the metal material and the electrolyte composition.

Current density: The current density directly affects the formation quality of the oxide film. If the current density is too high, the metal surface will react violently and the heat will be concentrated, which may cause local ablation or cracking of the oxide film, destroy the integrity of the film layer and reduce the insulation performance; if the current density is too low, the oxidation reaction will be slow, the oxide film will not be generated sufficiently, and the insulation performance will be difficult to reach the ideal level. Reasonable control of the current density can ensure the uniform growth of the oxide film and obtain good insulation effect.

Electrolyte composition: The composition of the electrolyte plays a vital role in the performance of the oxide film. Different metal materials require matching electrolytes to generate high-quality oxide films. For example, sulfuric acid, oxalic acid, etc. are often used as electrolytes for aluminum anodizing. The ion components in the electrolyte will affect the chemical composition and structure of the oxide film, thereby changing its insulation properties. At the same time, electrolyte additives (such as corrosion inhibitors, stabilizers, etc.) can also improve the compactness and corrosion resistance of the oxide film and improve the insulation performance.

4. Example analysis of the effect of oxidation process on insulation performance

Aluminum alloy dumbbell anodizing example: A fitness equipment manufacturer anodized a batch of aluminum alloy adjustable dumbbells. By optimizing the oxidation process parameters, the thickness of the oxide film reached 10μm-25μm. After testing, the insulation resistance of the dumbbells after oxidation treatment increased by 2 orders of magnitude compared with that before treatment, and the breakdown voltage was also significantly improved. The product has excellent insulation performance in high humidity and high voltage environments, effectively reducing the risk of electric shock to users and extending the service life of the product.

Stainless steel dumbbell oxidation example: When the stainless steel dumbbell is oxidized, a specific oxidation process is used to generate a dense chromium oxide film on its surface. The oxide film has good corrosion resistance and insulation. Even in harsh use environments, it can effectively prevent the stainless steel surface from degrading insulation performance due to oxidation corrosion, ensuring the safety and reliability of the product.

5. Advantages of the application of oxidation process in adjustable dumbbells

Improve product safety: As people pay more attention to fitness activities, the frequency and scenarios of adjustable dumbbells are increasing. Good insulation performance can prevent users from electric shock accidents due to electrical failures or humid environments during use, provide safety protection for consumers, and enhance product market competitiveness.

Extend product service life: The protective effect of the oxide film can reduce corrosion and wear on the metal surface, and reduce the risk of reduced insulation performance due to surface damage. In long-term use, the oxide film can effectively resist the erosion of the external environment on the metal, maintain the stability of the product's insulation performance, extend the service life of the adjustable dumbbells, and reduce the cost of use for consumers.

Enhance product reliability: For some professional fitness venues or special application areas, such as rehabilitation training centers, the reliability and stability of adjustable dumbbells are extremely high. The oxidation process can improve the insulation performance and anti-interference ability of the product, so that it can operate stably in a complex electromagnetic environment, ensure training effects and safety, and meet the needs of professional customers.

6. Development trend of oxidation process in adjustable dumbbell industry

Environmentally friendly oxidation process research and development: With increasingly stringent environmental protection requirements, traditional oxidation processes face challenges due to the pollution caused by waste liquid and waste gas. In the future, the adjustable dumbbell industry will increase investment in the research and development of environmentally friendly oxidation processes, such as chromium-free oxidation processes and electrolyte recycling and reuse technologies, to reduce pollutant emissions in the production process and achieve green production.

Multifunctional composite oxidation film development: In order to meet the market's high-performance demand for adjustable dumbbells, the development of composite oxidation films with multiple functions will become a trend. For example, the development of composite oxidation films with high insulation performance, good heat dissipation performance and antibacterial properties will not only improve the safety and comfort of product use, but also expand its application prospects in medical, smart fitness and other fields.

Intelligent oxidation process control: With the help of advanced sensor technology and automated control systems, real-time monitoring and precise control of oxidation process parameters are achieved. Through the intelligent control system, parameters such as oxidation time, temperature, current density, etc. can be automatically adjusted according to dumbbells of different materials and specifications to ensure the stability of the oxidation film quality and improve production efficiency and product quality consistency.

7. Conclusion

The oxidation process has a significant effect on improving the insulation performance of adjustable dumbbells. By reasonably controlling the process parameters, an oxide film with high insulation resistance, low dielectric loss, good surface discharge suppression and high breakdown voltage can be generated, which effectively protects the safety of users and extends the service life of the product. In the context of increasingly fierce market competition, adjustable dumbbell manufacturers should pay attention to the research and development and application of oxidation processes, continuously optimize process technology, and improve product quality and performance to meet the needs of international wholesale buyers for high-quality fitness equipment. At the same time, with the development of environmental protection and intelligent trends, actively exploring environmentally friendly oxidation processes and intelligent production models will bring broader development space to the adjustable dumbbell industry and promote the sustainable development of the industry.