The secret of ensuring the stability of the adjustable dumbbell adjustment device under dynamic load

The secret of ensuring the stability of the Adjustable Dumbbell adjustment device under dynamic load

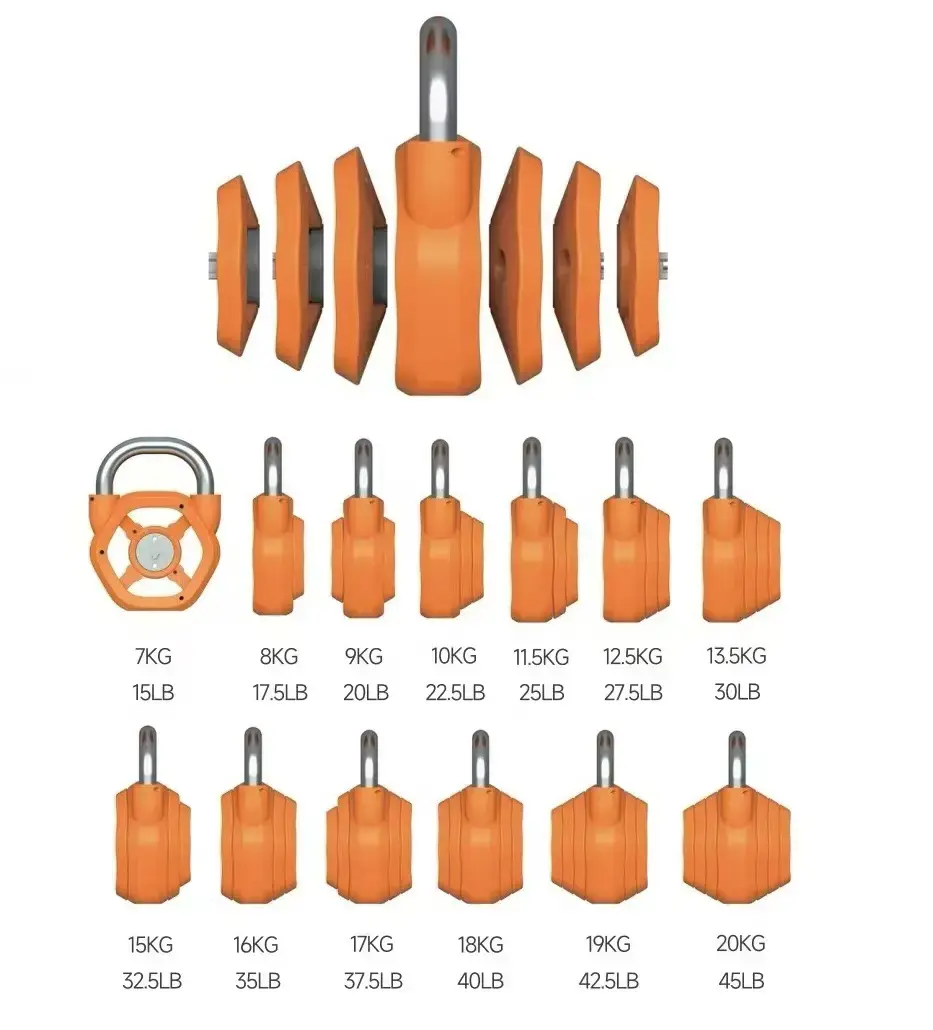

In the field of fitness equipment, Adjustable Dumbbells are gradually becoming the darling of the market. For independent stations targeting international wholesale buyers, product quality and performance are the key to attracting customers. The stability of the adjustable dumbbell adjustment device under dynamic load is undoubtedly one of the important criteria for measuring its quality. This article will explore in depth how to ensure the stability ofthe adjustable dumbbell adjustment device under dynamic load, and provide strong technical support and market competitiveness for your independent station products.

1. Common types and working principles of adjustable dumbbell adjustment devices

(I) Mechanical adjustment device

Thread locking type: By rotating the handle or knob, the threaded parts are tightened or loosened to fix or release the bell plate. Its working principle is based on the friction and mechanical locking between the threads. Under dynamic load, as long as the accuracy and tightness of the threads are appropriate, it can provide a relatively stable locking effect.

Cam locking type: The rotation of the cam is used to control the clamping and release of the bell plate. When the cam rotates to a certain angle, its raised part will press the weight plate tightly in the specified position, and the mechanical advantage and friction of the cam will keep the weight plate stable. For example, some adjustable dumbbells are equipped with cam devices on both sides of the handle. Rotating the handle can make the cam move, so as to achieve quick replacement and weight adjustment of the weight plate.

Bayonet locking type: The bell plate is fixed or released by inserting or pulling out the bayonet from the hole on the bell plate. Under dynamic load, the bayonet needs to have sufficient strength and locking force to prevent the bayonet from loosening or falling off due to vibration or impact.

(II) Electronic adjustment device

Electronic adjustment device is usually composed of motor, gear system, electronic control system, etc. The user selects the required weight through buttons or touch screens, and the electronic control system controls the motor to drive the gear to rotate, thereby driving the internal counterweight device (such as blades, sliders, etc.) to move, so as to adjust the weight of the dumbbell. For example, some intelligent adjustable dumbbells use motors to drive the blades to rotate. When the blades move to the appropriate position, the blade position is locked by the electronic control system to determine the weight of the dumbbell.

2. Factors affecting the stability of the adjustment device under dynamic load

(I) Material quality and performance

Insufficient strength: If the key components of the adjustment device, such as threaded components, cams, bayonet pins, motor housings, gears, etc., are not strong enough, they are prone to deformation, fracture or wear when subjected to dynamic loads, resulting in failure of the adjustment device or reduced stability. For example, low-quality plastic bayonet pins may break or deform after repeated pressure and impact, and cannot properly fix the bell plate.

Poor wear resistance: Under dynamic loads, there will be relative movement and friction between the components of the adjustment device. If the material has poor wear resistance, the surface of the component will wear rapidly, increasing the possibility of clearance and looseness, affecting the accuracy and stability of the adjustment device. For example, wear between threads will lead to reduced matching accuracy, slippage or loosening.

Unstable elastic modulus: For some components that rely on elastic deformation to achieve locking or buffering (such as springs, elastic bayonet pins, etc.), unstable elastic modulus of the material will affect their normal operation. Under dynamic loads, the elastic force of the elastic component may gradually weaken or change abnormally, resulting in the inability of the adjustment device to maintain a stable locking state or buffering effect.

(II) Design defects

Irrational structure: If the overall structural design of the adjustment device is not reasonable, stress concentration and uneven force will occur under dynamic load. For example, if the design of the connection between the handle and the bell plate is too narrow or irregular in shape, it will cause excessive local stress in this part when bearing force, which will cause deformation or fracture, affecting the stability of the adjustment device.

Improper size matching: The size matching accuracy between the components is crucial to the stability of the adjustment device. If the gap between the components is too large, it will cause loosening and shaking; if the gap is too small, it may cause jamming or excessive wear. For example, if the matching gap between the bayonet and the hole of the bell plate is too large, the bayonet is easy to loosen under dynamic load and cannot firmly fix the bell plate; if the gap is too small, it will make the bayonet difficult to insert or remove, affecting the convenience of adjustment.

Lack of effective anti-loosening measures: Under dynamic load, vibration and impact are common phenomena, which can easily cause the threaded connection, bayonet connection and other parts of the adjustment device to loosen. If effective anti-loosening measures, such as anti-loosening nuts, spring washers, locking nuts, bayonet locking devices, etc., are not considered in the design, the adjustment device may gradually lose stability during use, and even cause safety hazards such as bell pieces falling off.

(III) Manufacturing process and assembly quality

Insufficient processing accuracy: If the dimensional accuracy, shape accuracy and position accuracy of the adjustment device components do not meet the design requirements during the processing, it will affect the assembly and matching between the components. For example, insufficient processing accuracy of the thread will lead to inconsistent tightness of the threaded connection, affecting the locking effect; large processing errors in the contour shape of the cam will cause uneven distribution of contact pressure between the cam and the bell piece, reducing the locking stability.

Assembly error: During the assembly process, if the assembler operates improperly or the assembly process is unreasonable, it will cause assembly errors between components. For example, large deviations in the assembly coaxiality of the motor and the gear will lead to unstable gear transmission, vibration and noise, affecting the stability of the electronic adjustment device; inaccurate assembly positions of the handle and the bell piece will cause uneven force on the adjustment device under dynamic load, making it prone to failure.

Lack of quality inspection and control: During the manufacturing and assembly process, if there are no strict quality inspection and control measures, material defects, processing errors, assembly problems, etc. cannot be discovered and corrected in time, the quality of the adjustment device will be uneven, and it will be difficult to ensure stability under dynamic loads. For example, without functional testing and load testing of the assembled adjustment device, its performance and stability in actual use cannot be ensured.

3. Strategies and methods to ensure the stability of the adjustment device under dynamic loads

(I) Optimize material selection

Select high-strength alloy materials: For key load-bearing parts of the adjustment device, such as handles, threaded rods, camshafts, bayonet pins, etc., high-strength alloy materials such as high-strength aluminum alloys, titanium alloys, high-strength steels, etc. should be preferred. These materials have high yield strength and tensile strength, and can withstand large dynamic loads without plastic deformation or fracture. For example, a bayonet made of titanium alloy can reduce weight while ensuring strength, and improve the service life and reliability of the adjustment device.

Consider the wear resistance and surface treatment of materials: Selecting materials with good wear resistance and combining them with appropriate surface treatment processes, such as electroplating, sandblasting, oxidation, spraying wear-resistant coatings, etc., can significantly improve the wear resistance of the adjustment device components. Taking threaded parts as an example, the use of carbide coating or nitriding treatment can effectively reduce the wear of threads under dynamic loads, maintain the accuracy and connection strength of threads, and extend the service life of the adjustment device. At the same time, surface treatment can also improve the corrosion resistance of materials and prevent the reduction of component strength and functional failure caused by corrosion.

Ensure the stability of the elastic properties of materials: For elastic parts, such as springs and elastic bayonet pins, materials with stable elastic modulus and good fatigue resistance, such as high carbon steel, stainless spring steel, etc., should be selected, and the heat treatment process of the materials should be strictly controlled to ensure that they can maintain stable elasticity and deformation properties under long-term dynamic loads. For example, springs made of high-quality stainless spring steel can maintain stable elastic force within a large dynamic load range after precise heat treatment and processing, ensuring the normal functioning of the locking and buffering functions of the adjustment device.

(II) Improved design

Reasonable design of structure: According to the principles of mechanics and actual working conditions, the structure of the adjustment device is optimized to avoid stress concentration and uneven force. For example, the use of rounded corner transitions and reasonable distribution of reinforcing ribs can effectively reduce the stress concentration factor and improve the strength and stability of the structure. For the connection structure between the handle and the bell, it can be designed with a gradual cross-section or increase the support part to enhance its ability to withstand dynamic loads. At the same time, the force of the adjustment device in different directions and postures should be considered to ensure its stability and reliability under various dynamic load conditions.

Precise matching of dimensions: Using advanced computer-aided design (CAD) and computer-aided engineering (CAE) technology, the dimensions of each component of the adjustment device are accurately calculated and simulated to ensure that the matching accuracy between the components is optimal. In the design process, the influence of factors such as elastic deformation and thermal expansion of the material on the size matching should be fully considered, and appropriate compensation margins should be reserved. For example, for the matching size of the bayonet and the hole of the bell, the appropriate clearance or interference should be accurately calculated according to the characteristics of different materials, the temperature changes in the use environment, and the stress of the bayonet, so as to ensure that the bayonet can firmly fix the bell under dynamic load and facilitate insertion and extraction.

Increase anti-loosening and buffering design: In the design of the adjustment device, the anti-loosening and buffering requirements under dynamic load are fully considered. For threaded connection parts, anti-loosening measures such as anti-loosening nuts, spring washers, locking nuts, and double nut locking are adopted to prevent the threads from loosening; for bayonet connections, bayonet locking devices are designed, such as locking nuts and elastic locking sheets at the tail of the bayonet, to ensure that the bayonet will not loosen and fall off under dynamic load. At the same time, adding buffer elements such as rubber pads, spring pads, elastic rubber sleeves, etc. to the key parts of the adjustment device can effectively absorb and alleviate the vibration and impact force generated by dynamic loads, reduce damage to the components of the adjustment device, and improve its stability and service life. For example, setting a rubber pad between the handle and the bell can reduce direct collision and friction between the handle and the bell, reduce vibration transmission, and improve the comfort of the user and the stability of the adjustment device.

(III) Improve manufacturing process and assembly quality

Adopt advanced processing technology: Use high-precision processing equipment and advanced processing technology, such as CNC machining center, precision grinder, laser cutting, wire cutting, etc., to ensure that the processing accuracy of each component of the adjustment device meets the design requirements. For example, using CNC machining center to process threaded parts can accurately control the pitch, tooth angle and surface roughness of the thread, improve the connection strength and matching accuracy of the thread; using precision grinder to grind the profile of the cam can ensure the shape accuracy and surface quality of the cam, so that it can smoothly contact and transmit with the bell under dynamic load.

Strict assembly process and standards: Develop detailed and strict assembly process and operation standards, and provide professional training for assembly personnel to ensure the standardization and accuracy of the assembly process. During the assembly process, use appropriate assembly tools and equipment, such as torque wrenches, presses, special fixtures, etc., to ensure the assembly accuracy and connection strength between components. For example, when assembling the motor and the gear, they must be adjusted and fixed in strict accordance with the prescribed coaxiality requirements to ensure the stability and accuracy of the gear transmission; for the assembly of the bayonet and the handle, the assembly position and insertion depth must be controlled to ensure that the bayonet can move flexibly and accurately match the hole of the bell.

Establish a complete quality inspection system: Establish a quality inspection system for the entire process from raw material procurement to product delivery, and strengthen the monitoring and management of the quality of the adjustment device. In the raw material procurement stage, the chemical composition, mechanical properties, metallographic structure, etc. of the materials are strictly inspected to ensure that the quality of the raw materials meets the requirements; in the processing process, the parts of each process are sampled or fully inspected to promptly discover and correct processing errors and defects; after assembly, the adjustment device is subjected to a series of performance tests such as function testing, load testing, fatigue testing, and stability testing to simulate the dynamic load conditions in actual use, and check whether the adjustment performance, locking stability, durability and other indicators of the adjustment device meet the design standards. For products that fail the inspection, they must be reworked, repaired or scrapped in a timely manner to prevent the outflow of products with quality hazards and ensure that the adjustment device of each adjustable dumbbell can work stably and reliably under dynamic load.

4. Actual case analysis and experience reference

(I) Case 1: Stability improvement practice of a well-known brand of adjustable dumbbells

In its adjustable dumbbell products, the brand initially used ordinary carbon steel materials to manufacture threaded adjustment parts. Under high-intensity dynamic training, problems such as thread slippage and loosening frequently occurred, resulting in instability of the adjustment device, affecting user experience and product reputation. To solve this problem, the R&D team selected high-strength stainless steel materials after repeated tests and comparisons, and carried out fine rolling processing and special anti-corrosion treatment on the threads. At the same time, the structural design of the threads was optimized, the effective meshing length and tooth depth of the threads were increased, and the connection strength and fatigue resistance of the threads were improved. During the manufacturing process, the processing accuracy and assembly quality were strictly controlled, and high-precision thread processing equipment and professional assembly tools were used to ensure that the processing accuracy of the threaded parts reached the micron level, and the threaded connection after assembly was tight and reliable. Through these improvement measures, the stability of the adjustment device of the brand's adjustable dumbbells under dynamic loads has been significantly improved, the product failure rate has been greatly reduced, and user satisfaction has been effectively improved, further consolidating its position in the market.

(II) Case 2: Design and stability assurance of a new type of electronic adjustable dumbbell

A new fitness equipment manufacturer has launched a new type of electronic adjustable dumbbell, whose adjustment device uses advanced motor drive technology and intelligent control system. During the design stage, the R&D team fully considered the impact of dynamic load on the stability of the adjustment device, and used CAE software to conduct detailed mechanical analysis and simulation optimization of key components such as the motor, gear system, and counterweight device. In terms of material selection, the motor housing is made of high-strength aluminum alloy, the gear is made of high-strength alloy steel that has undergone special heat treatment, and the counterweight blade is made of high-density, high-hardness engineering plastics, and the surface is treated with a wear-resistant coating. In terms of manufacturing technology, high-precision CNC machining centers and advanced injection molding technology are used to ensure the dimensional accuracy and shape accuracy of each component. During the assembly process, strict quality inspection and control processes are implemented, and each assembly link is carefully inspected and tested. In addition, intelligent sensors and anti-loosening devices are added to the adjustment device to monitor the operating status and load conditions of the adjustment device in real time. Once an abnormality is found, the system will automatically adjust or issue an alarm. After a series of rigorous tests and actual use verification, this new electronic adjustable dumbbell has excellent stability under dynamic load, and can maintain precise weight adjustment and stable locking state in various high-intensity training scenarios. It has been widely praised by professional fitness coaches and fitness enthusiasts, and successfully opened up the international market share.

5. Summary and Outlook

Adjustable dumbbells have broad development prospects in the international fitness equipment market due to their convenience and versatility. For independent stations facing international wholesale buyers, ensuring the stability of adjustable dumbbell adjustment devices under dynamic loads is the key to winning customer trust and market share. By deeply analyzing the working principle of the adjustment device, the factors affecting stability, and adopting strategies and methods such as optimizing material selection, improving design, and improving manufacturing processes and assembly quality, and drawing on successful experiences in actual cases, we can effectively improve the stability and reliability of the adjustable dumbbell adjustment device, and provide strong guarantees for its competition in the international market.

In the future development, with the continuous advancement of science and technology and the continuous innovation of the fitness equipment industry New, adjustable dumbbell technology and design will be more perfect. For example, the application of new intelligent materials, more advanced electronic control technology integration, further optimization of ergonomic design, etc., will bring new opportunities and challenges to the stability improvement of adjustable dumbbell adjustment devices. As a fitness equipment supplier, we need to pay close attention to industry dynamics and technological development trends, and continuously invest in R&D and innovation to meet the international market demand for high-quality adjustable dumbbells and promote the widespread application and development of adjustable dumbbell products around the world.